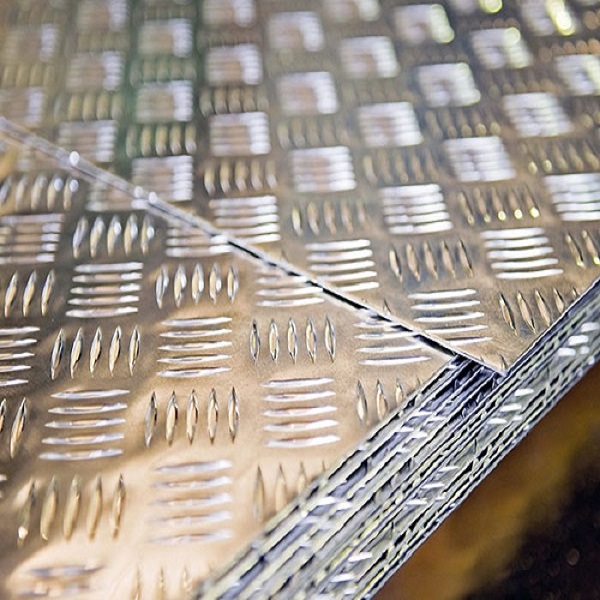

Aluminum checker plate, sometimes called aluminum tread plate, aluminum floor plate, or aluminum diamond plate.

Diamond aluminium tread plate or floor plate is widely used for a variety of structural, architectural and cosmetic applications.

A method has been developed to roll metal plates with an upraised “lug” pattern, providing the customer with several choices to best meet the needs of the project, with specific qualities of cleanability, impact resistance, support strength, and corrosion resistance.

Aluminum checker plates 3003 and 5052 are two common alloy aluminum plates. They have certain differences in chemical composition, mechanical properties, common specifications, scope of application and price.

Aluminum chequered plate 3003: It belongs to the AL-Mn series alloy. The main alloy element is manganese, and the aluminum content is slightly higher than that of 5052 aluminum plate.

Aluminum tread plate 5052: It belongs to Al-Mg series alloy, and the main alloy element is magnesium.

Mechanical properties

Tensile strength: The tensile strength of aluminum checker plate 3003 is between 145~195Rm/MPa, while the tensile strength of 5052 aluminum checker plate is as high as 230~280Rm/MPa, which is much higher than 3003 aluminum plate.

Elongation strength: The elongation strength of pattern aluminum plate 3003 is 115Rm/MPa, while the elongation strength of 5052 aluminum tread plate is 150Rm/MPa.

3003 aluminum checker plates are Mainly used in humid environments, such as product packaging, refrigerators, air conditioners, cold storages, ventilation ducts, etc.

It has good corrosion resistance, good weldability, and high plasticity, and is suitable for making low-load parts working in liquid or gas media.

5052 aluminum tread plates are commonly used in electrical casings, transportation vehicles, pressure vessels, etc. It is a common material for manufacturing automobiles and aircraft fuel tanks and oil pipes.

It has high fatigue strength and corrosion resistance, and cannot be strengthened by heat treatment. It has good weldability with resistance welding and atomic hydrogen welding.

Aluminum sheet 5052 is used in many types of industrial applications, including: Fuel tanks

Comparing with alloy 3003, In general, 3003 is fairly soft and has good corrosion resistance, good drawing, good workability, moderate strength, and is weldable, while 5052 is stronger and has better corrosion resistance, good drawing, good formability, higher strength, and also is weldable.

When annealed, aluminium alloy 5052 is stronger than 1100 and 3003 alloys. It is one of the higher strength, non-heat-treatable alloys and has good workability. It also has very good corrosion resistance, especially to salt water

Size of aluminum sheet

Thickness:0.2-6.0mm

Width:100-2400mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5-15 ton per size

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for .063 aluminum diamond plate,1050 1060 1100 aluminum diamond/checker plate sheets manufacture,1050 1060 3003 Aluminum Diamond Sheet Plate for Anti-Slip Floor Manufacturer, We warmly welcome customers from all over the world for any kind of cooperation with us to build a mutual benefit future. We are devoting ourselves wholeheartedly to offer customers the best service.