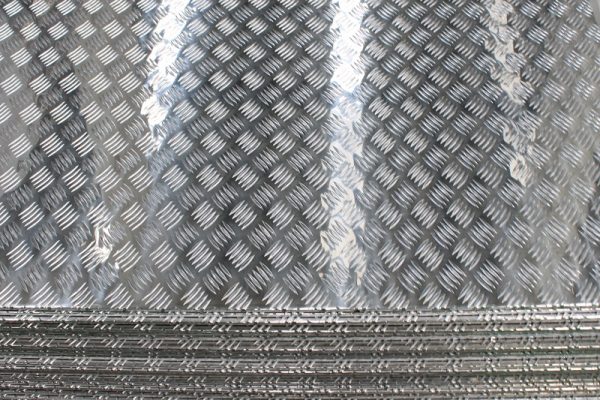

Aluminum 3003 H14 bare sheet for fabrication | decorative architectural uses 3003 5052 aluminum plate alloy factory

Aluminum Sheet 3003 H14 Bare is an excellent choice for chemical equipment and general sheet metal projects due to its superior corrosion resistance and good workability. Aluminum 3003 H14 bare sheet works well in fabrication and decorative architectural uses because it is highly workable, formable, and weldable, while being capable of withstanding outdoor weather

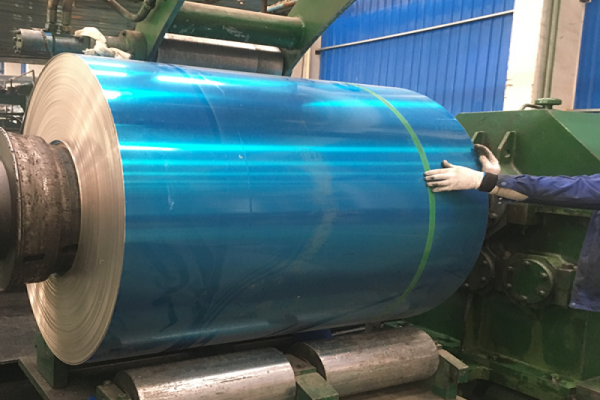

3003 aluminum plates react well to mechanical finishing and organic finishes. our aluminum sheet has a wide range of sizes readily available to the AMS 4008 for H14

3003 Aluminum Alloy has good machinability and welding is readily accomplished by means of conventional welding methods. Commonly used in chemical equipment, ductwork, and in general sheet metal work. 3003 Aluminum is typically used in stampings and the manufacturing of pressure vessels, builder’s hardware, garage doors, awning slats, refrigerator panels, gas lines, gasoline tanks, heat exchangers, drawn and spun parts, and storage tanks. All of our 3003 Aluminum Sheet is protected on one side with a protective vinyl film.

Chemistry of 3003 aluminum sheet

| Chemistry | |

| Iron (FE) | 0.70% max |

| Aluminum (Al) | 96.7 – 99% |

| Copper (Cu) | 0.05 – 0.20% |

| Chromium (Cr) | 0.10% max |

| Manganese (Mn) | 1.0 – 1.5% max |

| Silicon (Si) | 0.60% max |

Aluminum sheet metal is great for most custom metal fabrication.

The following are the most commonly used aluminum grades that our customers require.

1104-H14

Commercially pure aluminum, chemical and weather resistant. Ductile, with good weldability, but it is weak. RuiYi customers use it in jewelry and chemical applications.

2024-T3

2024 fabrication typically revolves around aerospace applications. This type of aluminum alloy has great machinability, fair corrosion resistance, is heat treatable and has good workability and appearance.

3003-H14

3003-H14 maintains good weldability and formability, and is corrosion resistant. customers use 3003-H14 in mail boxes, cabinets, tanks, stampings, spun and drawn parts, and fan blades.

5052 alloy has a higher strength and greater corrosion resistance (including to salt water). Its major alloying element is magnesium. Magnesium overcomes the corrosive effects of the iron present in the alloy. It also has better finishing characteristics than the 3003 alloy. These attributes make aluminum 5052 a great fit for food processing equipment and truck trailers as well as marine and aquatic feature

5052-H32

5052-H32 has been great for customer use in electronic chassis, tanks, and pressure vessels. While stronger than 3003 it is still formable and has high corrosion resistance and weldability.

6061-T6

6061-T6 is a head treatable structural alloy. customers like the great weldability, corrosion resistance, and great strength.