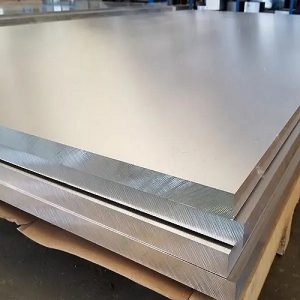

Aluminum sheets are commonly used in a variety of applications, from construction to transportation. To achieve the desired properties for specific applications, aluminum sheets are often made using different alloys.

3003 Aluminum Alloy

The 3003 aluminum alloy is one of the most commonly used alloys in the production of aluminum sheets. It is known for its excellent corrosion resistance, good formability, and high strength-to-weight ratio. This alloy is often used in the production of kitchenware, food and chemical handling equipment, and storage tanks.

5052 Aluminum Alloy

The 5052 aluminum alloy is another popular choice for the production of aluminum sheets. It is known for its high strength and excellent corrosion resistance, making it suitable for marine applications and outdoor construction. This alloy is often used in the production of fuel tanks, flooring, and wall panels.

6061 Aluminum Alloy

The 6061 aluminum alloy is a high-strength alloy commonly used in the production of structural components, such as aircraft parts, automotive parts, and bicycle frames. This alloy has excellent weldability, good corrosion resistance, and good formability.

7075 Aluminum Alloy

The 7075 aluminum alloy is a high-strength alloy that is often used in the production of aerospace components, such as aircraft wings and fuselage frames. It has excellent fatigue resistance and good machinability, but it is less corrosion-resistant than other aluminum alloys.

2024 Aluminum Alloy

The 2024 aluminum alloy is a high-strength alloy that is often used in the production of aircraft structures and other aerospace components. It has excellent fatigue resistance and good machinability, but it is not as corrosion-resistant as other aluminum alloys.

5086 Aluminum Alloy

The 5086 aluminum alloy is a high-strength alloy that is commonly used in the production of marine applications, such as boat hulls and decks. It has excellent corrosion resistance and good weldability.