Description

Aluminum 1100 is a commercially pure aluminum. 1100 aluminum sheet has excellent welding characteristics; it is also soft and ductile , so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 aluminum sheet is however non-heat treatable. As 1100 aluminum sheet has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications where eye appeal is important.

Aluminum 1100 can be shaped into many different products and most frequently appears in railroad tank cars, fin stock, dials, cooking utensils, name plans, chemical equipment, dials, and more. The plumbing and lighting industries also make frequent use of 1100 aluminum sheet, in addition to many other industries

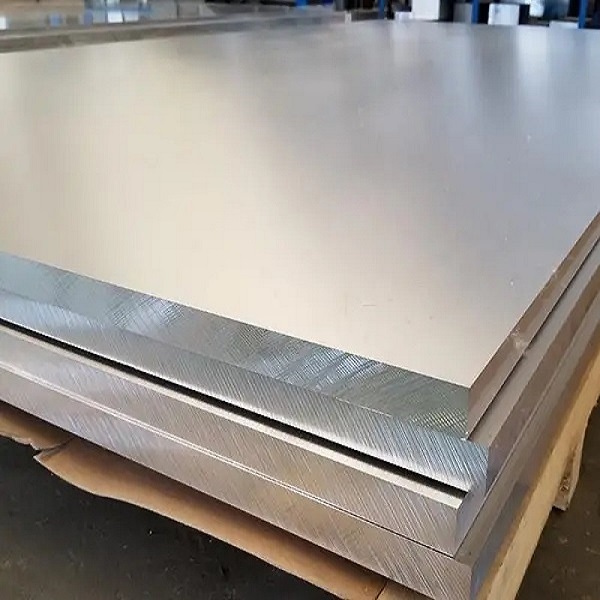

aluminum plate 1100 is a shiny smooth plate used in a variety of applications. Our aluminum plate 1100 range in thickness from 0.6mm to 6mm, or cut-to-length aluminum sheet is acceptable too.

Aluminum 1100 is just one of several common aluminum alloys and is soft, low strength and, at 99% min aluminum, is the commercially pure aluminum. Copper, iron, magnesium, manganese, silicon, titanium, vanadium and zinc comprise the remaining elements

Temper: F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Thickness:0.2-350mm

Width:100-2600mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5ton per size

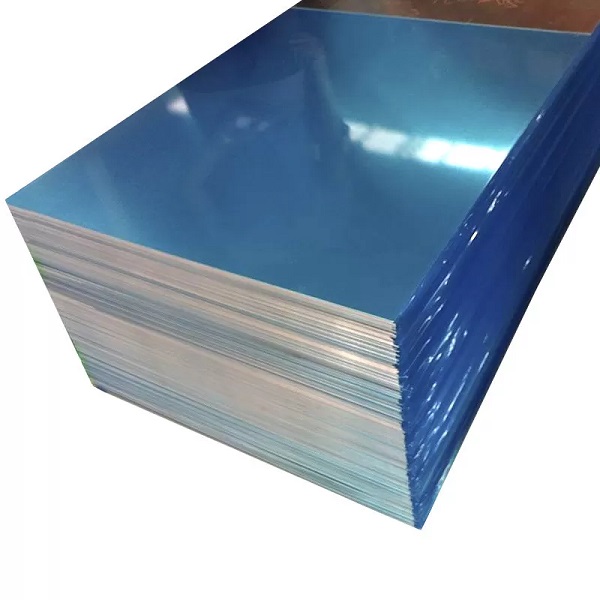

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209

Aluminum sheet 1100 alloy is widely used in fin stock, heat exchanger fins, spun hollowware, dials and name plates, decorative parts

1100 Aluminum Sheet of packaging meet the export standard. Plastic film and brown paper can be covered at customers’ need. wooden case or wooden pallet is adopted to protect products from damage during the delivery

–

–

–