وصف

5086 aluminum sheet is a rust-proof aluminum plate with medium strength, good corrosion resistance and excellent weldability. Its main chemical components include elements such as magnesium, السيليكون, نحاس, زنك, manganese and titanium.

Magnesium is the main alloying element, with a content between 3.5 و 4.5%. This kind of aluminum plate can obtain different mechanical properties through different heat treatment states, such as H116, and is suitable for different application scenarios.

The main applications of 5086 ورقة الألمنيوم include weldable parts for ships, automobiles and aircraft plates, as well as pressure vessels, refrigeration units, television towers, installation equipment, transportation equipment, missile parts, armor, إلخ. that require strict fire protection.

في هذه المناطق, 5086 aluminum sheet’s high corrosion resistance, good weldability and medium strength make it an ideal material choice.

5086 H116 aluminum sheet is an aluminum product with specific physical and chemical properties.

Here is a detailed explanation about it:

سمات: 5086 is a rust-proof aluminum with high corrosion resistance, good weldability and medium strength. This kind of aluminum plate is widely used in weldable parts of ships, automobiles and aircraft panels, as well as pressure vessels, refrigeration units, TV towers, installation equipment, transportation equipment, missile parts, armor and other occasions that require strict fire protection.

Chemical composition: التركيب الكيميائي لـ 5086 H116 aluminum plate includes magnesium (ملغ), زنك (الزنك), المنغنيز (Mn), التيتانيوم (منظمة الشفافية الدولية) and iron (Fe). بينهم, magnesium is the main alloying element, with its content ranging from 3.5 إلى 4.5%. Other elements are present in relatively low amounts to meet specific performance requirements.

Physical properties: The supply status of this aluminum plate can be O, H112, H116, H111, H321, H32, H36 or H38. Its density is 0.096 lb/cu in (2,660 kg/m3).

Mechanical properties: 5086 H116 aluminum plate has certain mechanical properties, such as conditional yield strength σ0.2 (ميغاباسكال) ≥ 95, elongation δ10 (%) ≥ 10, and elongation δ5 (%) ≥ 12.

الوضعية: Due to its excellent corrosion resistance, قابلية اللحام والقوة المتوسطة, 5086 H116 لوحة الألومنيوم is widely used in various occasions that require high corrosion resistance and medium strength, such as ships, سيارات, aircraft and other manufacturing industries, as well as those that require strict Fire prevention occasions.

In short, 5086 H116 aluminum plate is an aluminum product with excellent performance and wide range of uses. Its specific chemical composition and physical properties make it widely used in different fields.

لفائف الألمنيوم Supplier RAYIWELL MFG / RUIYI can offer ورقة الألمنيوم grade below

1000 سلسلة:1050,1060,1070,1080,1100,1145,1200,1235, إلخ.

2000 سلسلة:2014,2017,2018,2024,2025,2219, 2219,2618أ إلخ.

3000 سلسلة:3003,3004,3102,3104,3105,3005, إلخ.

4000 سلسلة:4032,4043, 4017, إلخ

5000 سلسلة: 5005,5052,5454,5754,5083,5086,5182,5082, إلخ.

6000 سلسلة:6061,6063,6262,6101, إلخ

7000 سلسلة:7072,7075,7003 إلخ

8000 سلسلة: 8011, إلخ.

سجية من صفائح الألمنيوم: ال, ح, دبليو, F, تي

ح:H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

تي: T0-T651

حجم ورقة الألمنيوم

سماكة:0.2-6.0مم

عرض:100-2400مم

الطول:200-11000مم

لفائف الأم: CC أو DC

وزن: حوالي 2mt لكل منصة نقالة للحجم العام

موك: 5طن لكل حجم

حماية: طبقة بين الورق, فيلم أبيض, فيلم أزرق, فيلم أبيض وأسود, فيلم مايكرو ملزمة, وفقا لمتطلباتكم.

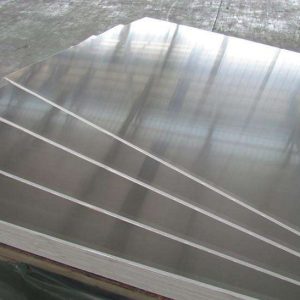

سطح - المظهر الخارجي: نظيف وسلس, لا بقعة ساطعة, تآكل, نفط, مشقوق, إلخ.

منتج قياسي: GBT3880, JIS4000, EN485, ASTM-B209

Aluminum coil refers to a rolled product rolled from pure aluminum or aluminum alloy materials. Its surface is silvery white and shiny.

This material offers several advantages, including light weight, كثافة قليلة, easy handling, المقاومة للتآكل, and long service life.

Due to these characteristics, aluminum coils are widely used in various fields, such as sheet metal parts and instrument casings for aircraft, automobiles and other transportation vehicles, as well as decorative components such as building doors, شبابيك, والجدران الستارية.

Aluminum coils can be classified according to thickness, width, alloy composition and surface treatment. According to thickness, aluminum coils can be divided into different specifications of 0.1-6mm; according to width, the common size is 600*2000mm.

According to alloy composition, aluminum coils can be divided into various grades, such as 1050, 1060, 1065, 1070, 1100, 1200, 1300, 1450, 1250, 1275a1, 1500, إلخ.

بالإضافة الى, the surface treatment methods of aluminum coils can also be divided into two methods: anodizing and electrophoretic coating. The color of anodizing can be sprayed according to user needs.

-

-

-