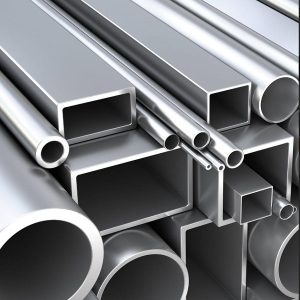

Aluminium Extrusion Profiles

Aluminium extrusion profiles are a popular manufacturing option for industries that require strong and durable materials for their products. Extrusion is a process by which a metal or plastic material is pushed through a die, which shapes it into a continuous, uniform cross-sectional profile. Aluminium extrusion profiles are used in a wide range of applications, including construction, وسائل النقل, electrical, and industrial.

aluminium extrusion profile

The Advantages of Aluminium Extrusion Profiles

One of the primary advantages of aluminium extrusion profiles is their strength-to-weight ratio. Aluminium is a lightweight metal, but it is also strong and durable. Extruded aluminium profiles can be designed to be very strong while maintaining a low weight, making them ideal for applications that require both strength and lightness. بالإضافة إلى ذلك, aluminium is resistant to corrosion and rust, which makes it suitable for outdoor applications.

Aluminium extrusion profiles can be designed to a wide range of shapes and sizes, depending on the requirements of the application. The flexibility of the extrusion process allows manufacturers to create complex shapes with tight tolerances, which can be difficult or impossible to achieve with other manufacturing methods. This makes الألومنيوم extrusion profiles an excellent choice for applications where precision and accuracy are essential.

Another advantage of aluminium extrusion profiles is their versatility. They can be finished in a wide range of ways, including anodising, لوحة, powder coating, or polishing. This allows manufacturers to achieve the desired aesthetic appearance for their products while also providing additional protection against corrosion and wear.

anodized aluminum extrusion profile

Applications of Aluminium Extrusion Profiles

Aluminium extrusion profiles have a wide range of applications in many industries. In the construction industry, they are commonly used for building facades, window frames, door frames, and curtain walls. The lightweight nature of aluminium makes it an ideal choice for large-scale construction projects, where the weight of the building materials is a critical factor.

In the transportation industry, aluminium extrusion profiles are used for body panels, frame components, and other structural elements in vehicles. The lightweight nature of aluminium makes it an excellent choice for improving fuel efficiency in cars and trucks, while its strength and durability ensure that it can withstand the stresses and strains of transportation.

In the electrical industry, aluminium extrusion profiles are used for heat sinks, enclosures, and other components that require excellent thermal conductivity. The high thermal conductivity of aluminium allows it to dissipate heat efficiently, making it an ideal material for components that generate heat during operation.

Aluminium extrusion profiles are available in various grades of aluminium, بما فيها 6061, 6063, و 6082. These grades offer varying levels of strength, المقاومة للتآكل, والقابلية للماكينة, making them suitable for different applications. فمثلا, 6061 is a high-strength alloy that is suitable for structural applications, في حين 6063 is more commonly used for architectural applications due to its excellent finishing properties.

The extrusion process also allows manufacturers to incorporate features such as slots, grooves, and holes into the profile. This eliminates the need for additional machining, reducing the production time and cost of the component. The design flexibility of aluminium extrusion profiles also enables manufacturers to create complex shapes that may not be possible with other manufacturing methods.

Aluminium extrusion profiles are also a sustainable manufacturing option. Aluminium is a highly recyclable material, and the extrusion process generates minimal waste. بالإضافة إلى ذلك, extruded aluminium profiles can be cut to the exact length required for the application, reducing material waste further.

In the industrial sector, aluminium extrusion profiles are used for conveyor systems, machinery frames, and other components that require high strength and durability. The lightweight nature of aluminium also makes it an ideal choice for applications that require high mobility or manoeuvrability, such as robotics or aerospace.

CONCLUSION

Aluminium extrusion profiles offer many advantages over other manufacturing methods, including their strength-to-weight ratio, versatility, and flexibility in design. They have a wide range of applications in many industries, including construction, وسائل النقل, and electrical. With their durability, المقاومة للتآكل, and ability to be finished in a range of ways, aluminium extrusion profiles are an excellent choice for many applications.