описание

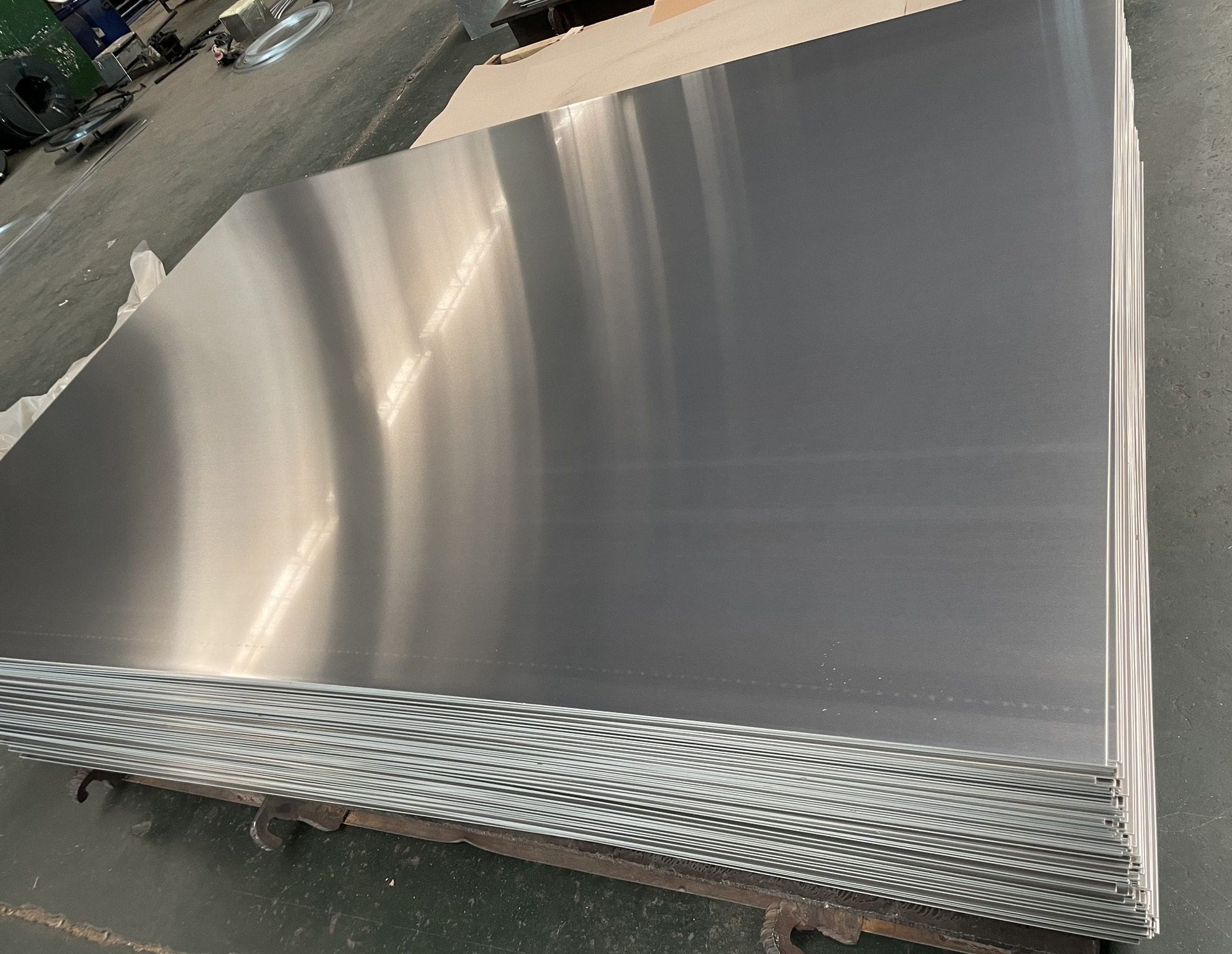

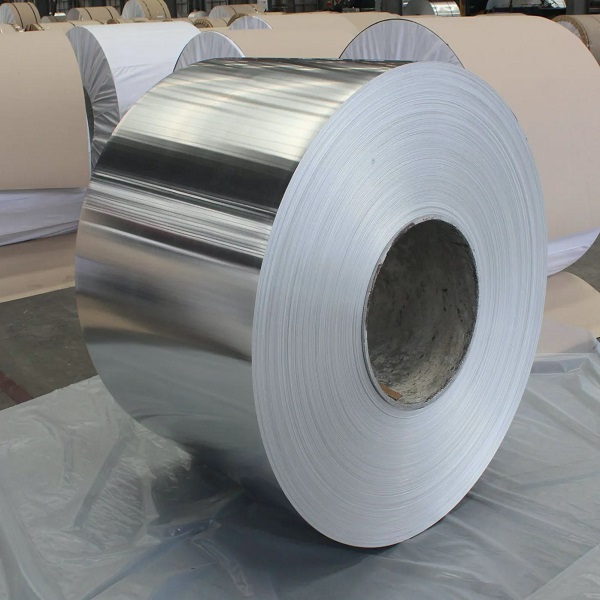

7075 aluminum sheet is a high-strength aerospace aluminum alloy that is commonly used in the manufacture of aircraft and other high-stress applications.

It has excellent strength-to-weight ratio and is resistant to stress corrosion cracking. The alloy is available in various thicknesses and sizes, and can be easily machined and formed. It is also heat treatable, which allows for further strengthening of the material.

7075 алуминиев лист is typically used in the construction of aircraft wings, рамки на фюзелажа, and other structural components. It is also used in the manufacturing of high-performance sporting equipment, such as bicycle frames and rock climbing gear.

Алуминиев лист / Табела 7075-T6/T651 обикновено се използва за космическото пространство, военен, и автомобилни приложения. 7075 алуминий е най-здравият алуминий, със здравината на много стомани, като същевременно запазва лекотата на алуминия и устойчивостта на корозия.

| сплав | нрав | дебелина | широчина |

| 7075 | T651 | 4-260mm | 1200-3800mm |

| 7075 | T7651 | 4-260mm | 1200-3800mm |

| 7075 | T7351 | 4-260mm | 1200-3800mm |

Механични свойства

| Състояние на сплавта | Посока | дебелина (mm) | Издръжливост на опън | Провлачване | Удължение при скъсване | стандарт |

| 7075-T651 | LT | 6-260 | 570-590МРа | 495-515МРа | 10-13.5 | GB/T3880 |

| 7075-T7651 | LT | 6-102 | 550-560МРа | 480-490МРа | 10.5-12.5 | AMS4045K |

| 7075-T7351 | LT | 6-102 | 500-520МРа | 420-435МРа | 10-12.5 | AMS4078 |

алуминий 7075 е член на 7000 серия, който има цинк като основен легиращ компонент и е добре известен със своята изключително висока якост. След това темперирането може допълнително да подобри неговата висока механична якост. Това свойство прави сплав 7075 много популярен в космическата и отбранителната промишленост.

| Типични механични свойства на 7075 алуминиева пластина | ||||

| нрав | дебелина

(mm) |

Издръжливост на опън

(МРа) |

Провлачване

(МРа) |

Удължение

(%) |

| T6 | 1~3.2 | 540 | 470 | 8 |

| T6 | 3.2~6.3 | 540 | 475 | 8 |

| T651 | 6.3~12.5 | 540 | 460 | 9 |

| T651 | 25~50 | 530 | 460 | — |

| T651 | 60~80 | 495 | 420 | — |

| T651 | 90~100 | 460 | 370 | |

Неговата здравина е сравнима с тази на много видове стомана, но има много по-ниска плътност. Сплавта е отличен заместител на стоманата при приложения с високо напрежение. Той също така отлично издържа на стрес от умора, което го прави много надежден, качество, много търсено в индустриите, споменати по-горе.

сплав 7075 предлага само средна устойчивост на корозия, резултат от малкото количество мед, включено в неговия химичен състав. Той също така се характеризира с разумна обработваемост и лошо формоване и заваряемост. Друг недостатък на тази сплав е, че има сравнително висока цена в сравнение с други алуминиеви сплави поради изключително високата си якост.

РАЙУЕЛ MFG or RuiYi Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Quality could full meet AMS aviation standard.

стандарт

Bare: AMS QQ-A-250/12, BS 2 L95, AMS 4038, AMS 4045, AMS 4039, AMS 4049, AMS 4044, AMS 4045, AMS 4078, QQ-A-250/24, AIR 9048.690, AIR 9048.700, AIR 9048.710, AIR 9049, и т.н..

AlClad: AMS QQ-A-250/13, BS 2 L88, AMS 4046, AMS 4048, AMS 4049, QQ-A-250/18, QQ-A-250/25, QQ-A-250/26, и т.н..

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

In what application scenarios can 7075 aluminum alloy not replace other materials?

7075 алуминиев лист и aluminum rods are important members of aluminum alloy materials. They are widely used in many fields due to their high strength, добри механични свойства, excellent corrosion resistance and wear resistance.

На първо място, 7075 aluminum alloy is a high-strength heat-treatable alloy. Its strength is far greater than that of ordinary hard aluminum, and it has excellent weldability and corrosion resistance. This makes it irreplaceable in aerospace, автомобилостроенето, shipbuilding and other fields.

В космическата сфера, 7075 aluminum sheet plate and aluminum rods are often used to manufacture aircraft parts, such as wings, fuselages, engine casings, и т.н., because they can significantly reduce the weight of aircraft and improve flight performance and fuel economy.

In automobile manufacturing, they are used to make body parts, wheels, suspension systems, и т.н., aiming to improve the overall performance and fuel economy of the car.

на второ място, 7075 aluminum plates or aluminum sheets and aluminium rods also have good processing performance and wear resistance, which makes them useful in the fields of electronic products and sports equipment manufacturing.

In the field of electronic products, they are used to manufacture electronic equipment casings, heat sinks and other components to improve the heat dissipation efficiency and protection performance of the equipment.

In the manufacturing of sports equipment, 7075 aluminum sheets and aluminum rods are often used to make sports equipment such as hiking poles, bicycle frames, полюси, and ski poles due to their lightweight and durable properties.

7075 aluminum alloy is widely used in many fields due to its high strength, wear resistance, отлична устойчивост на корозия, and good electrical and thermal conductivity.

Especially in situations where high material performance requirements are required, 7075 aluminum alloy shows its unique advantages.

Specifically, in the aerospace field, which has extremely high requirements for the strength and corrosion resistance of the material, 7075 aluminum alloy has become an ideal choice due to its excellent performance.

Например, 7075 aluminum alloy plays an irreplaceable role in the manufacturing of key components such as aircraft parts, wings, fuselages and engine casings.

по същия начин, in the field of automobile manufacturing, 7075 aluminum alloy materials are often used in components such as high-strength bolts, aluminum alloy cylinders, and automobile bodies.

-

-

-