opis

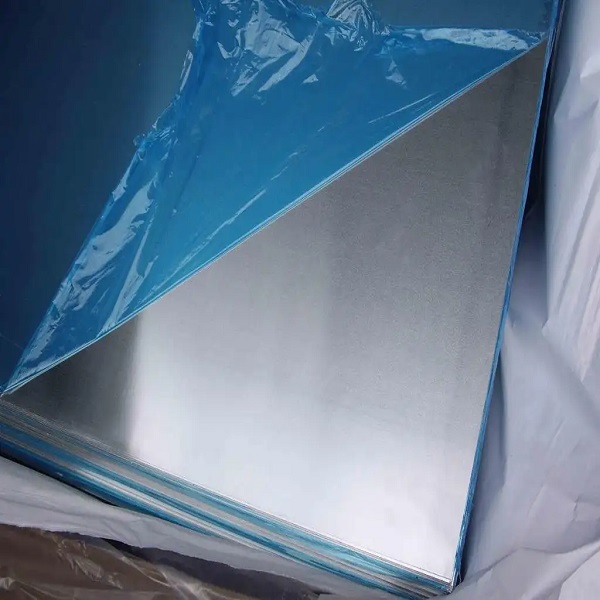

Aluminum pad printing cliches is a technique used in the pad printing process, što je metoda prenošenja slike ili dizajna na površinu.

Aluminum pad printing cliches is a plate or pad that is made from aluminum and has the desired image or design etched or engraved onto its surface. Kliše se zatim premazuje mastilom, a na kliše se pritisne silikonski jastučić, pokupi mastilo sa urezanih područja.

Silikonska podloga se zatim utiskuje na površinu koja se štampa, prenošenje mastila na željeni predmet. Ovaj proces omogućava precizno i detaljno štampanje na različitim materijalima, uključujući aluminijum.

Aluminum pad printing cliches are preferred in pad printing due to their durability, jer mogu izdržati višekratnu upotrebu bez trošenja ili gubitka oblika. Takođe pružaju odličan prenos mastila, što rezultira visokokvalitetnim otiscima.

To create an aluminum cliche, dizajn ili slika se prvo kreiraju digitalno ili crtaju rukom. Dizajn se zatim prenosi na fotoosjetljivi premaz koji se nanosi na aluminijskih ploča. Ova obložena ploča je izložena UV zračenju, koji stvrdnjava premaz u područjima gdje je slika prisutna.

Nakon izloženosti, neočvrsli premaz se ispere, ostavljajući iza sebe reljef dizajna na aluminijskoj ploči. Ploča se zatim tretira rastvorom za jetkanje kako bi se produbio reljef i osigurao pravilan prenos mastila.

Aluminum pad printing plates play an important role in the printing industry and are favored mainly for their unique material properties and wide range of applications.

Characteristics of Aluminum pad printing cliches / aluminum pad printing plates

Good thermal conductivity: aluminijum, as a metal, has good thermal conductivity, which is particularly important in the pad printing process.

During the pad printing process, the pad printing oil needs to be dried before it can be completely transferred to the surface of the printed matter. The aluminum pad printing plate can speed up the drying speed of the pad printing oil through its efficient thermal conductivity, thereby improving pad printing efficiency.

High strength and stability: The aluminum pad printing plate / Aluminum pad printing cliches is not only light in weight, but also has high strength and stability, which allows it to maintain excellent performance in high-speed, large-volume printing production and reduce defects caused by material deformation or wear. Printing quality issues.

Flexible surface treatment: Aluminum pad printing plates have various surface treatments, which facilitate engraving and etching. This provides printing companies with a wider creative space and can produce more exquisite and complex prints.

Economical and practical: Compared with other materials such as stainless steel, aluminum pad printing plates are more economical in price. U isto vrijeme, their excellent performance can meet most printing needs, so they are very cost-effective.

Application of aluminum pad printing plate

Aluminum pad printing plates / Aluminum pad printing cliches are widely used in various printing fields, including but not limited to:

Logo and trademark printing: Pad printing technology is often used to print corporate logos, trademarks and other patterns on the surface of products. The aluminum pad printing plate ensures the clarity and consistency of the printed pattern with its high precision and stability.

Electronic product printing: In the manufacturing process of electronic products, aluminum pad printing plates are used to print text, symbols and other identification information on printed circuit boards. This information is of great significance for product assembly, testing and maintenance.

Packaging and decorative printing: Aluminum pad printing plates are also widely used in the printing of packaging materials and decorations, such as food packaging, cosmetic packaging, gift boxes, itd, to enhance the added value and attractiveness of products through exquisite printing patterns

What are the advantages and disadvantages of using Aluminum pad printing cliches in the printing industry?

Advantages

High precision: Aluminum pad printing cliches can transfer images and text to printing materials with high precision, ensuring the exquisiteness and clarity of printed matter. This is especially important for prints that require fine patterns and text, such as electronic product logos, cosmetic packaging, itd.

Stability and durability: Aluminum material has high strength and stability, which allows aluminum pad printing plates to maintain excellent performance in high-speed, large-volume printing production and reduce printing quality problems caused by material deformation or wear. U isto vrijeme, the service life of the aluminum pad printing plate is relatively long, reducing the frequency and cost of replacement.

Flexible surface treatment: Aluminum pad printing plates have various surface treatments, which facilitate engraving and etching. This provides printing companies with a wider creative space and can produce more exquisite and complex prints. dodatno, the aluminum pad printing plate can also be coated as needed to improve its corrosion resistance, wear resistance and other properties.

Economical and practical: Compared with other materials such as stainless steel, aluminum pad printing plates are more economical in price. U isto vrijeme, their excellent performance can meet most printing needs, so they are very cost-effective.

Environmental protection: Aluminum pad printing plates can be recycled and reused, which is in line with the current trend of environmental protection and sustainable development. During the printing process, using aluminum pad printing plates also helps reduce waste generation and environmental pollution.

Disadvantages

High skill requirements for operators: The printing process of aluminum pad printing plates requires operators to have high skills and experience to ensure printing quality and efficiency. If the operator’s skills are insufficient or the operation is improper, the quality of the printed matter may be reduced or the production efficiency may be reduced.

Maintenance cost: Although the aluminum pad printing plate has a long service life, it still requires regular maintenance and upkeep during use, such as cleaning, inspection, itd. These maintenance tasks require a certain amount of manpower, material and financial resources, which increases maintenance costs.

Limited scope of application: Although aluminum pad printing plates are used in many fields, their scope of application is still limited. Na primjer, on some special materials or printed materials with special requirements, other types of printing plates or printing technologies may need to be used.

Adaptability to inks and solvents: The adaptability of aluminum pad printing plates to inks and solvents may be subject to certain limitations. Different inks and solvents may have different effects on aluminum pad printing plates, such as corrosion, discoloration, itd. stoga, when choosing inks and solvents, you need to consider their adaptability to aluminum pad printing plates.

Anodizirani aluminijski lim je poseban metalni proizvod proizveden elektrohemijskom reakcijom. Tokom procesa proizvodnje, aluminijumski lim se stavlja u odgovarajući elektrolit (kao što je sumporna kiselina, hromna kiselina, oksalne kiseline, itd) kao anoda, a elektroliza se vrši pod specifičnim uslovima i dejstvom spoljne struje.

Nakon elektrolize, na površini aluminijumske ploče će se formirati film od aluminijum oksida. Njegova debljina je obično između 5 i 20 mikrona, a tvrdi anodizirani film može doprijeti 60 u 200 mikrona. Ovaj oksidni film ne samo da poboljšava tvrdoću i otpornost na habanje aluminijske ploče, ali i daje dobru otpornost na toplinu, izolacija i otpornost na koroziju.

Anodizirana aluminijumski lim se široko koriste u mnogim oblastima, uključujući gradnju, opremanje doma, elektronika, mehanički dijelovi, dijelovi za avione i automobile, precizni instrumenti i radio oprema, kućišta mašina, osvetljenje lampe, potrošačka elektronika, rukotvorine, kućanskih aparata, unutrašnja dekoracija, Signage, namještaj, auto dekoracija, itd.

|

razred

|

1050, 1060, 1070, 1100, 5050, 5052

|

|

Završna obrada

|

Boja anodizirana Reflective Mirror (Puder) Premazan brušeni (Anodizirana) Peskareno (Anodizirana) |

|

boja

|

Ecru, crn, Plava, Zlato, Sliver, crven, Ružičasto zlato, običaj

|

|

Veličina lista(mm)

|

330*625, 610*406, 1220*2440, Prilagođeno

|

|

debljina(mm)

|

0.3-10mm, standard: 0.5mm, 0.6mm, 0.8mm, 1.0mm, 2.0mm, itd

|

Anodizirani aluminijski lim nudi niz karakteristika i prednosti. Kao prvo, ima jaku otpornost na koroziju i može efikasno produžiti svoj radni vek. drugo, kao osnovni materijal, sama aluminijumska ploča ima dobru otpornost na vatru i može efikasno sprečiti širenje plamena.

dodatno, anodiziranog aluminijskih pločatakođe imaju karakteristike dobre obradivosti, otpornost na vremenske uslove, jak metalni osećaj, jaka otpornost na mrlje i snažna primjena. Lako se savija i oblikuje i izvodi brzo štancanje, i mogu se direktno prerađivati u proizvode, što uvelike smanjuje ciklus proizvodnje proizvoda i troškove.

U isto vrijeme, njegova površina ima veliku tvrdoću, dobra otpornost na ogrebotine, bez pokrivanja boje, zadržava metalnu boju aluminijumske ploče, i povećava ocjenu i dodanu vrijednost proizvoda.

Mi smo vodeći dobavljač ploča za tampon štampu (klišeji) za sve mašine za tampon štampu. Isporučujemo nekoliko vrsta ploča za tampon štampu:

- Lasersko gravirane ploče za tampon štampanje

- Polimerne ploče za tampon štampanje koje se mogu prati alkoholom

- Polimerne ploče za tampon štampanje koje se mogu prati u vodi

- Čelične ploče za tampon štampanje od tankog i debelog čelika

Sve naše ploče se mogu isporučiti u bilo kojoj željenoj veličini. i, ako je potrebno, opremljen sa izbušenim rupama za bilo koju mašinu za tampon štampu na tržištu.

-

-

-