Beskrivelse

6061 aluminiumsplade Fabrikant RAYIWELL MFG supply aluminum-silicon-magnesium alloy, strengthened by precipitation hardening. This alloy has medium strength, formbarhed, svejsbarhed, bearbejdelighed og korrosionsbestandighed.

aluminiumsplade 6061 T6 temper has an ultimate tensile strength of at least 42,000 psi (290 MPa) and yield strength of at least 35,000 psi (241 MPa). In thicknesses of 0.250 tomme (6.35 mm) or less, it has elongation of 8% eller mere; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties.

Legering 6061 alumium plate has a relatively high strength, easily welded and is widely used not only for making bicycle frames, but also in construction, fly, shipbuilding.

The main alloying elements in 6061 aluminiumplade are magnesium and silicon, med moderat styrke, god korrosionsbestandighed, weldability and oxidation effect. Widely used in various industrial structures requiring certain strength and high antibiotic corrosion resistance.

The main chemical components are: kobber 0.15-0.4%, silicium 0.4-0.8%, jern 0.7%, mangan 0.15%, magnesium 0.8-1.2%, zink 0.25%, chromium 0.04-0.35%, Titanium 0.15%.

The difference between 6061 aluminiumplade T6 and T651 is that, under normal circumstances, the internal stress of T6 will be relatively large, and it will be deformed during processing. The most suitable state for processing should be T651, stretched on the basis of T6, and eliminate internal stress.

6061-T6 : cooling after solution heat treatment to achieve high strength, no cold working;

6061-T651 : Cooling after solution heat treatment to achieve high strength, and then cold stretching by stretching machine to eliminate residual internal stress after heat treatment, so as to ensure the precision of machined products without deformation after deep processing.

6061 T6 Aluminium Plate is a commonly used aluminum alloy. Unless otherwise specified, it is generally in the 6061 T6, og 6061 T651 is the best feature of the 6-series aluminum alloy, and it is a fighter in the 6000-series aluminium legering. It has excellent processing performance, excellent welding characteristics and electroplating performance, god korrosionsbestandighed, high toughness, no deformation after processing, dense material without defects, easy polishing, easy coloring and film formation and excellent oxidation effect.

Since 6061-T651 is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process, although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, excellent processing performance and excellent welding Features and electroplating, god korrosionsbestandighed, høj sejhed og ingen deformation efter behandling, compact material without defects and east to polish, Let at farve film, Fremragende oxidationseffekt og andre fremragende egenskaber. The representative applications of 6061-T651 include aerospace fixtures, elektriske armaturer, and communication fields, og er også meget brugt i automatiserede mekaniske dele, præcisionsbearbejdning, fremstilling af forme, elektronik og præcisionsinstrumenter, SMT, PC board solder carriers, etc.

The states of 6061 aluminiumsplader are O temper, T4, T6, T651, etc. For different states, the application fields are different. 6061 aluminum plate has high strength, good anti-corrosion and anti-oxidation effects, and is widely used in automatic mechanical parts, præcisionsbearbejdning, automobile chassis, cake molds, etc., and is deeply loved by users.

Both the 6061-T6 aluminiumplade and the 6061-T651 aluminum plate are commonly used. The difference between the T6 state of the 6061 aluminum plate and the T651 is:

The internal pressure of T6 is high, and the processing deformation is more suitable for processing. The state is T651, which eliminates internal stress on the basis of T6 extension. The main alloy elements of 6061 aluminum plate are magnesium and silicon, which have medium strength, høj styrke, weldability and good oxidation effect.

Temperament: T1,T2,T3, T4, T6, T651

Tykkelse:0.2-350mm

Bredde:30-2600mm

Længde:200-11000mm

Moder spole: CC eller DC

Vægt: Ca. 2mt pr. palle for generel størrelse

MOQ: 5-10ton pr størrelse

Beskyttelse: papir mellemlag, hvid film, blå film, sort-hvid film, mikrobundet film, henhold til dine krav.

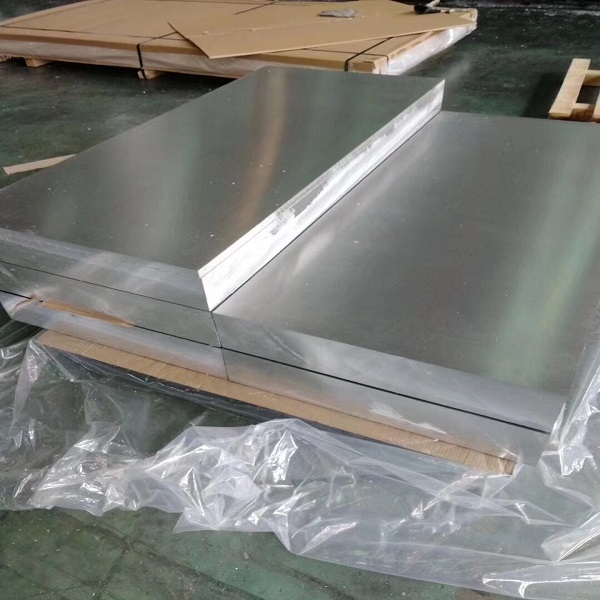

Overflade: ren og glat, ingen lys plet, korrosion, olie, slidset, etc.

Standard produkt: GBT3880, JIS4000, EN485, ASTM-B209, EN573, ASTMB221, AMS-QQ-A-200/8, ASMESB221

Leveringstid: omkring 30 dage efter modtagelse af depositum

Betaling: T/T, L/C til syne

Handelsbetingelser: FOB, CIF, CFR

Andet aluminiumplade alloy available

1000 serie:1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 serie:2014,2017,2018,2024,2025,2219, 2219,2618en osv.

3000 serie:3003,3004,3102,3104,3105,3005, etc.

4000 serie:4032,4043, 4017, etc

5000 serie: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 serie:6061,6063,6262,6101, etc

7000 serie:7072,7075,7003 etc

8000 serie: 8011, etc.

Aluminium ark or aluminum plate is used in construction material and building material. Inklusive: tagplade, loft, i væg, skillevæg, skodder, vinduesgardin, Port,

altan, væg, vejafmærkning, gadeskilte, vejbeskyttelsesplade, motorvejs beskyttelsesplade, brobærervæg, stillads, skibsplade, etc.

Aluminiumsplade bruges i elektriske maskinkomponenter. Inklusive: beskyttelsesplade, beskyttelsesboks, kondensator boks, tank med strømkondensator, elektrolytisk kondensator, batterivariabel, volumen skaft, højttalerramme, skifteplade, halvleder radiator, magnetisk disk, motorramme, fan blade, el-komfur, kølefinne, køleplade, etc

-

-

-