Beschreibung

6061 Aluminiumteller Hersteller RAYIWELL MFG supply aluminum-silicon-magnesium alloy, strengthened by precipitation hardening. This alloy has medium strength, Formbarkeit, Schweißbarkeit, Zerspanbarkeit und Korrosionsbeständigkeit.

Aluminiumteller 6061 T6 temper has an ultimate tensile strength of at least 42,000 psi (290 MPa) and yield strength of at least 35,000 psi (241 MPa). In thicknesses of 0.250 Zoll (6.35 Millimeter) or less, it has elongation of 8% oder mehr; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties.

Legierung 6061 alumium plate has a relatively high strength, easily welded and is widely used not only for making bicycle frames, but also in construction, Flugzeug, shipbuilding.

Die wichtigsten Legierungselemente in 6061 Aluminiumteller are magnesium and silicon, mit mäßiger Stärke, gute Korrosionsbeständigkeit, weldability and oxidation effect. Widely used in various industrial structures requiring certain strength and high antibiotic corrosion resistance.

The main chemical components are: Kupfer 0.15-0.4%, Silizium 0.4-0.8%, Eisen 0.7%, Mangan 0.15%, Magnesium 0.8-1.2%, Zink 0.25%, chromium 0.04-0.35%, Titan 0.15%.

The difference between 6061 Aluminiumteller T6 and T651 is that, under normal circumstances, the internal stress of T6 will be relatively large, and it will be deformed during processing. The most suitable state for processing should be T651, stretched on the basis of T6, and eliminate internal stress.

6061-T6 : cooling after solution heat treatment to achieve high strength, no cold working;

6061-T651 : Cooling after solution heat treatment to achieve high strength, and then cold stretching by stretching machine to eliminate residual internal stress after heat treatment, so as to ensure the precision of machined products without deformation after deep processing.

6061 T6 Aluminium Plate is a commonly used aluminum alloy. Unless otherwise specified, it is generally in the 6061 T6, und 6061 T651 is the best feature of the 6-series aluminum alloy, and it is a fighter in the 6000-series Aluminium Legierung. It has excellent processing performance, excellent welding characteristics and electroplating performance, gute Korrosionsbeständigkeit, high toughness, no deformation after processing, dense material without defects, easy polishing, easy coloring and film formation and excellent oxidation effect.

Since 6061-T651 is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process, although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, excellent processing performance and excellent welding Features and electroplating, gute Korrosionsbeständigkeit, hohe Zähigkeit und keine Verformung nach der Bearbeitung, compact material without defects and east to polish, leicht zu färben film, ausgezeichnete Oxidationswirkung und andere hervorragende Eigenschaften. The representative applications of 6061-T651 include aerospace fixtures, elektrische armaturen, und Kommunikationsfelder, und werden auch häufig in automatisierten mechanischen Teilen verwendet, Präzisionsbearbeitung, Formenbau, Elektronik und Präzisionsinstrumente, SMT, Lötträger für Leiterplatten, etc.

The states of 6061 Aluminiumplatten are O temper, T4, T6, T651, etc. For different states, the application fields are different. 6061 aluminum plate has high strength, good anti-corrosion and anti-oxidation effects, and is widely used in automatic mechanical parts, Präzisionsbearbeitung, automobile chassis, cake molds, usw., and is deeply loved by users.

Both the 6061-T6 Aluminiumteller and the 6061-T651 aluminum plate are commonly used. The difference between the T6 state of the 6061 aluminum plate and the T651 is:

The internal pressure of T6 is high, and the processing deformation is more suitable for processing. The state is T651, which eliminates internal stress on the basis of T6 extension. The main alloy elements of 6061 aluminum plate are magnesium and silicon, die eine mittlere Stärke haben, hohe Festigkeit, weldability and good oxidation effect.

Temperament: T1, T2, T3, T4, T6, T651

Dicke:0.2-350Millimeter

Breite:30-2600Millimeter

Länge:200-11000Millimeter

Mutterspule: CC oder DC

Gewicht: Ungefähr 2mt pro Palette für allgemeine Größe

MOQ: 5-10Tonne pro Größe

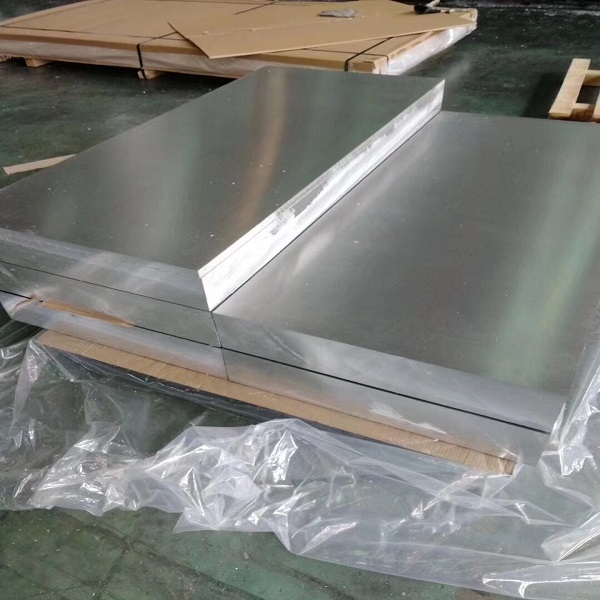

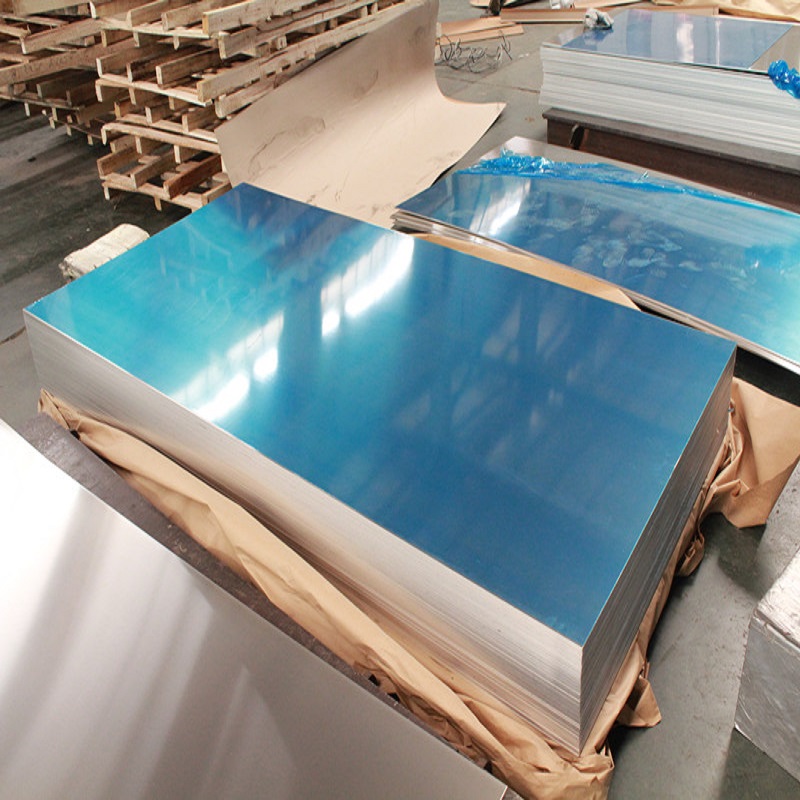

Schutz: Papierzwischenlage, weiße Folie, blaue Folie, Schwarz-Weiß-Film, mikrogebundener Film, entsprechend Ihrer Anforderung.

Oberfläche: sauber und glatt, kein heller Fleck, Korrosion, Öl, geschlitzten, etc.

Standardprodukt: GBT3880, JIS4000, EN485, ASTM-B209, EN573, ASTMB221, AMS-QQ-A-200/8, ASMESB221

Lieferzeit: ungefähr 30 Tage nach Erhalt der Anzahlung

Zahlung: T/T, L/C auf Sicht

Handelsbedingungen: FOB, CIF, CFR

Andere Aluminiumteller alloy available

1000 Serie:1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 Serie:2014,2017,2018,2024,2025,2219, 2219,2618ein usw.

3000 Serie:3003,3004,3102,3104,3105,3005, etc.

4000 Serie:4032,4043, 4017, etc

5000 Serie: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 Serie:6061,6063,6262,6101, etc

7000 Serie:7072,7075,7003 etc

8000 Serie: 8011, etc.

Aluminiumblech or aluminum plate is used in construction material and building material. Einschließlich: Dachplatte, Decke, Unterputz, Trennwand, Fensterläden, Rollo, Tor,

Balkon, Mauer, die Straßenmarkierung, Straßenschilder, Straßenschutzplatte, Autobahnschutzplatte, Brückenträgerwand, Gerüst, Schiffsplatte, etc.

Aluminiumblech wird in elektrischen Maschinenkomponenten verwendet. Einschließlich: Schutzplatte, Schutzbox, Kondensatorbox, Tank des Leistungskondensators, Elektrolytkondensator, Variable der Batterie, Volumenschacht, Lautsprecherrahmen, Schalterplatte, Halbleiterstrahler, Magnetplatte, Motorrahmen, die Hölle geht, Elektroherd, Kühlrippe, Kühlkörper, etc

-

-

-