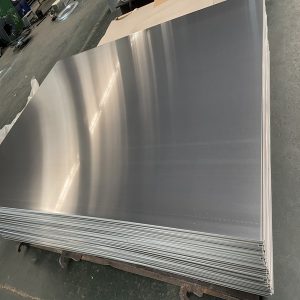

5052 aluminum sheets are a popular choice in numerous industries, ranging from aerospace and marine to automotive and construction.

These sheets are made from an aluminum-magnesium alloy, which enhances their strength and corrosion resistance. The addition of magnesium also improves the formability of 5052 Aluminiumbleche, making them highly malleable and easy to work with.

When it comes to choosing the right material for your project, aluminum is often the preferred choice due to its exceptional strength, lightweight nature, and resistance to corrosion.

Among the various aluminum alloys available in the market, 5052 aluminum sheets stand out for their remarkable versatility and durability. In this blog post, we will explore the incredible features and applications of 5052 Aluminiumbleche, as well as their counterparts, das 5052 Aluminiumplatte und 5052 aluminum coated coil.

One of the key advantages of 5052 aluminum sheets is their versatility. These sheets can be easily fabricated into various shapes and sizes, making them suitable for an extensive range of applications.

Whether you require flat panels, intricate parts, or complex structures, 5052 aluminum sheets can be customized to meet your specific needs. Außerdem, these sheets can be easily welded, allowing for seamless integration into your projects.

Another notable feature of 5052 aluminum sheets is their exceptional durability. The alloy’s corrosion resistance makes it ideal for outdoor applications where exposure to moisture and harsh weather conditions is a concern. Whether it is for marine vessels, architectural facades, or automotive components, 5052 aluminum sheets offer long-lasting performance and retain their appearance even in challenging environments.

The versatility and durability of 5052 aluminum sheets make them suitable for a wide range of applications. In the aerospace industry, these sheets are used for aircraft fuel tanks, Flügel, and fuselage components. In der Schifffahrtsindustrie, they are utilized for boat hulls, decks, and superstructures.

Zusätzlich, 5052 aluminum sheets find applications in the automotive industry for body panels, chassis components, and heat shields. Their corrosion resistance also makes them an excellent choice for architectural and decorative purposes.

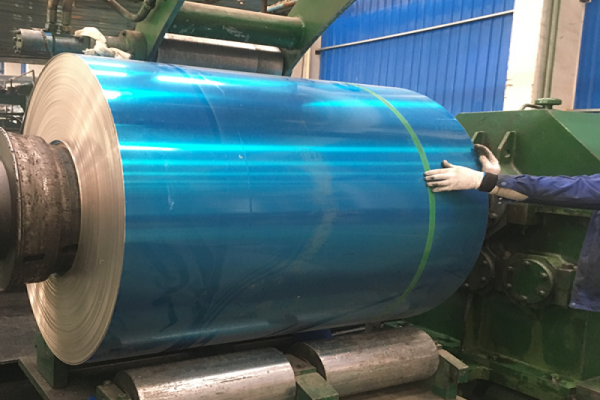

In addition to 5052 Aluminiumbleche, das 5052 aluminum plate and coated coil variants offer similar benefits and applications. Das 5052 aluminum plate is thicker and provides increased strength, making it suitable for heavy-duty applications such as truck beds and industrial equipment.

Andererseits, das 5052 aluminum coated coil is often used for roofing, Verkleidung, and insulation purposes, thanks to its enhanced resistance to weathering and UV rays.

5052 Aluminiumbleche, Platten, and coated coils are versatile and durable materials that find applications across various industries. Their exceptional strength, lightweight nature, and corrosion resistance make them an ideal choice for projects that require longevity and reliability.

Whether you are in the aerospace, Marine, Automobil, or construction industry, considering 5052 aluminum sheets will undoubtedly contribute to the success and longevity of your project.

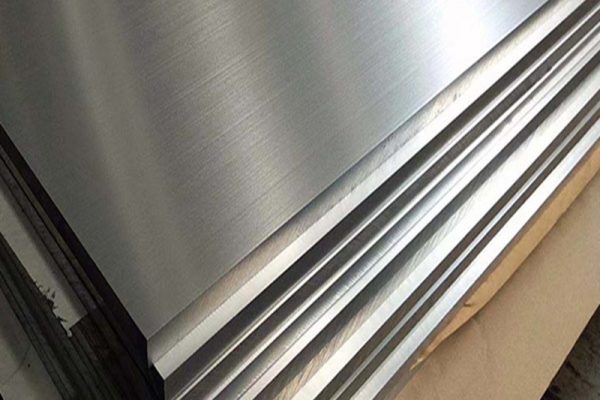

5052 aluminum sheet Vs 3003 Aluminiumblech

5052 Aluminiumblech und 3003 aluminum sheet are both popular choices for various applications due to their excellent properties. Jedoch, there are some differences between the two.

1. Composition:

– 5052 aluminum sheet is an alloy that primarily consists of aluminum, Magnesium, and chromium. It is known for its high strength and corrosion resistance.

– 3003 aluminum sheet is an alloy that primarily consists of aluminum and manganese. It is known for its good formability, Schweißbarkeit, und mäßige Stärke.

2. Strength:

– 5052 aluminum sheet has a higher tensile strength and yield strength compared to 3003 Aluminiumblech. This makes it more suitable for applications where strength is required, such as in marine environments or structural applications.

– 3003 aluminum sheet has a lower strength compared to 5052 Aluminiumblech. It is commonly used in applications where strength is not the primary concern, such as in packaging, Beschilderung, or cooking utensils.

3. Corrosion Resistance:

– Beide 5052 und 3003 aluminum sheets have good corrosion resistance. Jedoch, due to the presence of magnesium and chromium in 5052 Aluminiumblech, it offers better resistance to saltwater corrosion and atmospheric corrosion compared to 3003 Aluminiumblech.

4. Formability:

– 5052 aluminum sheet has good formability and can be easily formed into various shapes and sizes. It is suitable for applications that require complex forming or bending.

– 3003 aluminum sheet has excellent formability and can be easily formed, especially in thicker gauges. It is commonly used in applications that require deep drawing, spinning, or stamping.

In summary, while both 5052 Aluminiumblech und 3003 aluminum sheet have their own advantages, the choice between the two depends on the specific requirements of the application. If high strength and corrosion resistance are important, 5052 aluminum sheet is preferred. If good formability and moderate strength are required, 3003 aluminum sheet is a suitable choice.