Περιγραφή

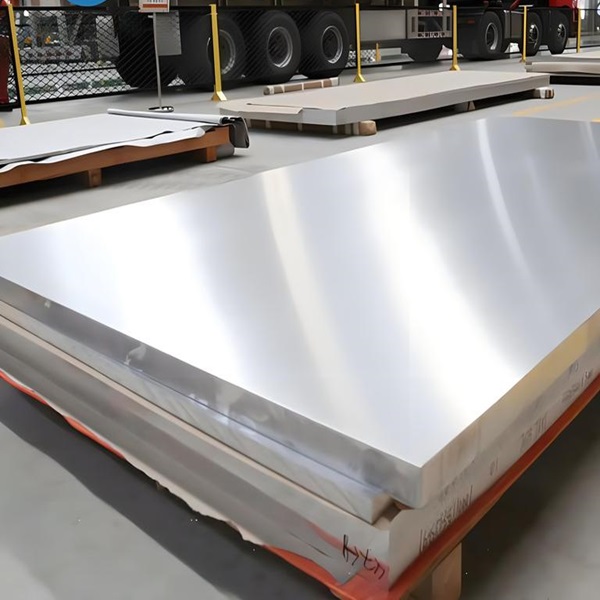

5454 H32 aluminum sheet is an aluminum alloy sheet that has been strain hardened and stabilized. It is commonly used in the aerospace industry for its high strength and corrosion resistance properties.

ο “H32” designation refers to the tempering process, which involves heating the φύλλο αλουμινίου and then cooling it rapidly to achieve the desired hardness

5454 aluminum alloy is an aluminum-magnesium alloy with high strength, good plasticity and excellent corrosion resistance. Its tensile strength and yield strength are higher than other aluminum alloy materials, while maintaining good formability and welding performance.

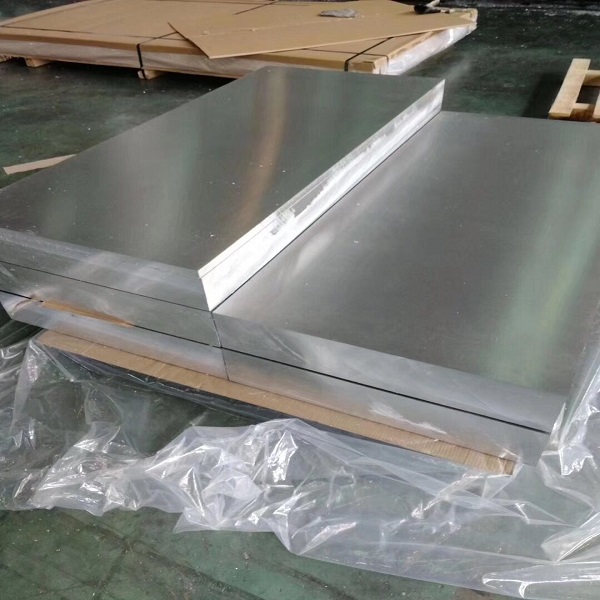

After heat treatment in the H32 state, the hardness of 5454 aluminum alloy can reach 70~80HB, significantly improving its strength and hardness.

The surface of the alloy is not easy to form an oxide layer and has good resistance to corrosive media such as seawater and chloride. It is suitable for special applications such as marine environments and chemical equipment.

Επιπλέον, 5454 aluminum alloy also has good low-temperature properties and is suitable for use under low-temperature working conditions, such as cryogenic storage tanks, liquefied natural gas (LNG) δεξαμενές αποθήκευσης, και τα λοιπα.

5454 H32 aluminum plate is widely used in ships, θαλάσσια μηχανική, oil tankers, δοχεία πίεσης, automobile bodies and other fields. Σε αυτές τις περιοχές, it meets the high requirements for material strength, corrosion resistance and processability.

5454 πλάκα αλουμινίου can be heat treated in various states, including O, H32, H34, και τα λοιπα., to change its mechanical properties and organizational structure.

5454 H32 aluminum sheet has good plasticity and processing performance, can be cold and hot processed, and can be easily formed and processed into various complex shapes.

Standard of 5454 Φύλλο αλουμινίου H32:

- ASTM B209

- ASTM B221

- ASTM B234

- ASTM B241

- ASTM B404

- ASTM B547

- ASTM B548

- QQ A-200/6

- QQ A250/10

- SAE J454

5454 Aluminum Sheet Chemistry Composition & αλλά δεν μπορεί να υπερβεί το μέγιστο βάθος ελαττωμάτων 0,5 mm & Χαρακτηριστικά:

| Element | και | Fe | με | Mn | mg | Cr | Ti | Zn | al |

|---|---|---|---|---|---|---|---|---|---|

| Standard Value | ≤0,25 | ≤0.40 | ≤0.10 | 0.50-1.0 | 2.4-3.0 | 0.05-0.20 | ≤0.20 | ≤0,25 | Υπόλοιπο |

| Actual Value | 0.06 | 0.28 | 0.03 | 0.87 | 2.77 | 0.09 | 0.02 | 0.02 | Υπόλοιπο |

| Κράμα & Ιδιοσυγκρασία | Tensile Strength Mpa | Elongation(%) | Yield Strength Mpa | Επιφάνεια |

|---|---|---|---|---|

| 5454 H32 | 250-305 | >8 | >180 | Qualified |

| 5454 ο | 215-275 | >18 | 109 | Qualifie |

| Κράμα | Ιδιοσυγκρασία | Πάχος | Πλάτος | Μήκος |

| 5454 | φά, ο, H12, Η14, H16, H18,H19,

H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321 |

0.3-600 | 20-2650 | 500-16000 |

5052 aluminum plate is commonly used in architecture, vehicles, και γενικά μεταλλουργία. 5454 aluminum plate has better weldability than 5052 πλάκα αλουμινίου, which makes it more suitable for applications that require welding.

The magnesium content of 5052 aluminum plate is between 2.2-2.8%, and the tensile strength is 170-305MPa. Compared with 5454 φύλλο αλουμινίου, it has a wider range of uses, especially in the construction industry.

Κράμα αλουμινίου 5454 έχει πολύ καλή αντοχή στη διάβρωση, ιδίως στο θαλασσινό νερό και στις γενικές περιβαλλοντικές συνθήκες. Η αντοχή είναι μέτρια προς υψηλή και παρόμοιο κράμα 5754 με καλή αντοχή στο εύρος θερμοκρασίας 65 προς την 170 βαθμούς Κελσίου. Έχει υψηλή αντοχή στην κόπωση. It is not suitable for complex or fine extrusions.

εφαρμογές 5454 χρησιμοποιείται συνήθως σε:

~ Road Transport Body-Building

~ Cemical and Process Plant

~ Pressure Vessels, Δοχεία, Boilers

~ Cryogenics

~ Marine & Off-shore incl. Masts,

~ Pylons, poles & masts

-

-

-