شرح

6061 aluminum plate is a heat-treated reinforced alloy sheet with good formability, جوش پذیری, ماشین کاری, and moderate strength, which can maintain good operability after annealing.

Magnesium-aluminum 6061-T651 is the main alloy of the 6-series alloy, and it is a high-quality aluminum alloy product that has undergone heat treatment and pre-stretching. دارای ویژگی های عالی مانند فیلم رنگ آمیزی آسان و اثر اکسیداسیون عالی است.

6061 ورق آلومینیوم is Widely used in various industrial structural parts that require a certain strength and high corrosion resistance, مانند تولید کامیون, ساختمان های برج, کشتی ها, تراموا, railway vehicles.

6061 آلیاژ آلومینیوم is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2XXX series or 7XXX series, its magnesium and silicon alloys have many characteristics, excellent processing performance and excellent welding characteristics. And electroplating, مقاومت به خوردگی خوب, چقرمگی بالا و بدون تغییر شکل پس از پردازش, dense material without defects and easy to polish, easy to color film, excellent oxidation effect and other excellent characteristics.

عناصر آلیاژی اصلی 6061 آلیاژ آلومینیوم منیزیم و سیلیکون است, and form Mg2Si. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; there is still a small amount of conductive material. copper to offset the adverse effects of titanium and iron on electrical conductivity; zirconium or titanium can refine grains and control recrystallization; in order to improve machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial aging hardening function. عناصر آلیاژی اصلی در 6061 آلیاژ آلومینیوم منیزیم و سیلیکون است, که استحکام متوسطی دارند, مقاومت به خوردگی خوب, جوش پذیری, و اثر اکسیداسیون خوب.

The general purpose 6061 آلومینیوم Plate is heat treatable, در برابر ترک خوردن در اثر استرس مقاومت می کند, and is easy to weld and machine, اما محدود به شکل پذیری.

6061 Aluminum plate is ideal for structural framing, صفحات پایه, گوست ها, هواپیما, marine and automotive parts, و غیره

زیرا 6061 aluminium alloy is easy to extrude, it can provide a variety of product forms such as sheet, strip, صفحه, میله, آهنگری, لوله ها, لوله های, سیم ها, extruded parts and structural shapes. آلومینیوم 6061 مقاومت در برابر خوردگی خوب, mechanical properties, شکل پذیری, جوش پذیری, and machinability.

It belongs to 6000 سلسله (آل گرم-سی) alloy aluminum sheet and has good weldability. همزمان, 6061 aluminum coil sheet has excellent aluminum-magnesium composition ratio and strong corrosion resistance. The hardness is 95HB (برینل), easy to process and form, non-stick knife

6061 Aluminium Aging 6061 aluminium alloy sheets, صفحات, rolled or cold-rolled wire, میله ها, کافه, and drawn tubing are aged to a metal temperature of 160 درجه سانتی گراد (320 °F) and maintaining it for 18h. Extruded rods, میله ها, shapes and tubes; dies and hand forgings, rolled rings are aged to a metal temperature of 175 درجه سانتی گراد (345 °F) and held for 8 ساعت ها

خوی: T1,T2,T3, T4, T6, T651

ضخامت:0.2-350میلی متر

عرض:30-2600میلی متر

طول:200-11000میلی متر

کویل مادر: CC یا DC

وزن: حدود 2 متر در هر پالت برای اندازه عمومی

MOQ: 5-10تن در هر اندازه

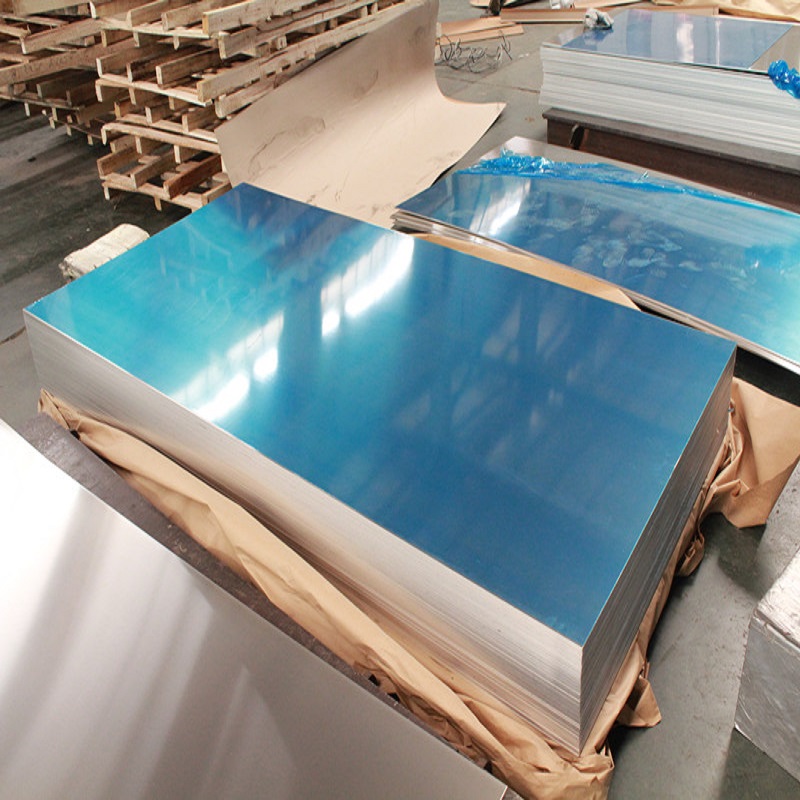

حفاظت: کاغذ بین لایه, فیلم سفید, فیلم آبی, فیلم سیاه و سفید, فیلم میکرو باند, با توجه به نیاز خود را.

سطح: تمیز و صاف, بدون لکه روشن, خوردگی, روغن, شکاف دار, و غیره.

محصول استاندارد: GBT3880, JIS4000, EN485, ASTM-B209, EN573

زمان تحویل: حدود 30 روز پس از دریافت سپرده

پرداخت: T/T, L/C در دید

شرایط معامله: FOB, CIF, CFR

The 6061 alloy is one of the most common for extrusion, but you may be considering other options for your particular application. Below are some other common alloys that are often considered as alternatives.

6061 و 6063 are the two most popular extrusion alloys. 6063 aluminum occupies the number one spot and 6061 occupies spot number two. As alloys in the 6000 سلسله, they both have magnesium and silicon as their primary alloying elements. بدین ترتیب, they have many similar properties. 6061 offers higher strength, با این حال. As such, it is often used for more structural applications. 6063, از سوی دیگر, is used for applications such as railing or trim, پنجره ها, and doors, due to its better appearance and corrosion resistance.

پسندیدن 6061, 5052 aluminum has magnesium as a primary alloying element. In the case of 5052, it is the only primary alloying element. 6061 has silicon as well. One of the key benefits of this alloy is its high level of weldability compared to other alloys. For projects where weldability is key, it is worth considering. One downside to 5052, though, is that it is not heat treatable. It is good for a variety of welding applications and it works well in marine applications due to its high corrosion resistance.

Primarily used in aerospace applications, را 2024 alloy is known for high strength. Its main alloying element is copper, and although it is strong and has good fatigue resistance, it is less machinable and more difficult to weld than 6061. It also offers poor corrosion resistance and is often used in wing and fuselage structures which come under high tension.

A member of the 6000 سلسله, 6061 aluminum’s main alloying elements are magnesium and silicon, and it’s a great example of a jack of all trades. The alloy is somewhat universal, seeing some exposure in structural and building products as well as the aerospace and recreation industries.

آلیاژ 6061 aluminum plate displays good tensile strength, which can be improved by temper treatment, and good corrosion resistance, جوش پذیری, and workability. Its workability makes it the right choice for many extrusion projects, as it is easy to form.

The alloy is widely available at a relatively low cost and is a great option to produce varied and precise components in different shapes. Although alloy 6061 doesn’t rank first in any aluminum properties tier list, it’s a great and reliable all-around aluminum alloy to work with.

-

-

-