Deskripsi

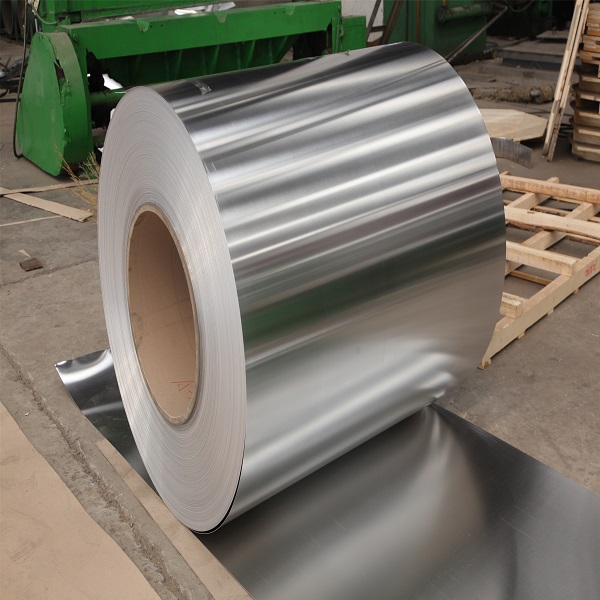

Aluminium coil adalah produk logam yang mengalami flying shear setelah digulung oleh mesin casting dan rolling dan diproses dengan menggambar dan menekuk sudut.

Kumparan aluminium banyak digunakan dalam elektronik, kemasan, konstruksi, mesin-mesin, dll. RAYIWELL MFG / RuiYi Aluminium sebagai salah satu produsen koil aluminium di China, teknologi produksi telah menyusul negara-negara maju.

According to the different metal elements contained in aluminium coil, it can be roughly divided into 9 kategori. , yang dapat dibagi menjadi 9 seri.

1000 seri

The representative 1000 series aluminium coil is also called pure aluminum plate. Among all the series, itu 1000 series belongs to the series with the most aluminum content. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in conventional industries at present. Most of the circulating in the market are 1050 dan 1060 seri.

The minimum aluminum content of the 1000 seri kumparan aluminium is determined according to the last two Arabic numerals. Sebagai contoh, the last two Arabic numerals of the 1050 seri adalah 50. Menurut prinsip penamaan merek internasional, the aluminum content must reach 99.5% or more to qualify as a product. my country’s aluminum alloy technical standard (gB/T3880-2006) also clearly stipulates that the aluminum content of 1050 should reach 99.5%. In the same way, kandungan aluminium dari 1060 series aluminum plates must reach more than 99.6%.

2000 seri plat aluminium

Representative 2A16 (LY16) 2A06 (LY6) 2000 series aluminum plate is characterized by high hardness, among which the content of copper is the highest, tentang 3-5%. Itu 2000 series aluminum plate belongs to aviation aluminum, which is not commonly used in conventional industries. There are fewer manufacturers of 2000 series aluminum sheets in my country.

3000 seri plat aluminium

Rep. 3003 3003 3A21-based. It can also be called anti-rust aluminum plate. The production process of 3000 series aluminum plate in China is relatively excellent. Itu 3000 series aluminum plate is mainly composed of manganese. The content is between 1.0-1.5. It is a series with better anti-rust function. Routinely used in humid environments such as air conditioners, lemari es, and undercars, the price is higher than the 1000 seri, and it is a more commonly used alloy series.

4000 seri plat aluminium

The aluminum plate represented by 4A01 4000 series belongs to the series with higher silicon content. Usually the silicon content is between 4.5-6.0%. It belongs to building materials, bagian mekanik, forging materials, welding materials; low melting point, good corrosion resistance Product description: Has the characteristics of heat resistance and wear resistance.

5000 seri

Represents the 5052.5005.5083.5A05 series. Itu 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy.

The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series. Karena itu, it is often used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries. The processing technology is continuous casting and rolling, which belongs to the series of hot-rolled aluminum plates, so it can be used for oxidation deep processing.

6000 seri

It means that 6061 mainly contains magnesium and silicon, so the advantages of 4000 seri dan 5000 series are concentrated. 6061 is a cold-processed aluminum forged product, suitable for applications requiring high corrosion resistance and oxidation resistance. Good workability, excellent interface characteristics, easy coating, good processability. Can be used on low pressure weapons and aircraft connectors.

General characteristics of 6061: excellent interface characteristics, easy coating, kekuatan tinggi, kemampuan kerja yang baik, and strong corrosion resistance.

Kegunaan khas dari 6061 aluminium: aircraft parts, camera parts, couplers, marine accessories and hardware, electronic accessories and joints, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts .

7000 seri

On behalf of 7075 mainly contains zinc. It also belongs to the aviation series. It is an aluminum-magnesium-zinc-copper alloy. It is a heat-treatable alloy. It belongs to superhard aluminum alloy and has good wear resistance.

The thick 7075 aluminum plate is all ultrasonically detected, which can ensure no blisters and impurities.

The high thermal conductivity of the 7075 aluminum plate can shorten the forming time and improve work efficiency.

The main feature is that the hardness is high. 7075 is a high-hardness, high-strength aluminum alloy, which is often used in the manufacture of aircraft structures and futures. It requires high-stress structural parts with high strength and strong corrosion resistance, and mold manufacturing.

8000 seri

The more commonly used is 8011 which belongs to other series. In my memory, the aluminum plate is mainly used as a bottle cap, and it is also used in radiators, most of which are aluminum foil. Not very commonly used.

9000 seri

It belongs to the spare series, and the technology is so advanced. In order to cope with the emergence of aluminum plates containing other alloying elements, the International Aluminum Strip Federation specifically indicated that the 9000 series is a spare series, waiting for another new variety to fill the gap of the 9000 seri.

Kumparan aluminium was called aluminum plates or sheets, dengan ketebalan 0.2 mm ke 500 mm, lebar dari 2600 mm, dan panjang 16 meter. semakin banyak strip).

Pelat aluminium mengacu pada pelat persegi panjang yang digulung dari ingot aluminium, yang dibagi menjadi pelat aluminium murni, paduan plat aluminium, plat aluminium tipis dan plat aluminium tebal sedang.

Pelat aluminium banyak digunakan dalam konstruksi, kemasan, AC, lemari es, energi matahari, kosmetik dan industri lainnya, dan juga dapat digunakan untuk anti korosi dan pelestarian panas di pembangkit listrik, pabrik kimia dan petrokimia.

The raw materials of kumparan aluminium are mainly pure aluminum, hot-rolled aluminum or aluminum alloy cast-rolled aluminum coils. Bahan baku ini dimasukkan ke dalam cold rolling mill dan digulung menjadi gulungan aluminium tipis dengan ketebalan dan lebar berbeda, dan kemudian gulungan aluminium dimasukkan ke dalam mesin slitting untuk menggorok. Strip aluminium dengan lebar berbeda yang terbentuk setelah pemotongan dapat memainkan peran mereka sendiri dalam operasi yang sebenarnya.

There are many classifications of aluminium coil, seperti 1050, 1060, 1070, 1100, 3003, 3004, dll. Ada dua keadaan utama strip aluminium: keadaan lunak dan keadaan keras. Keadaan lunak diwakili oleh huruf O, dan keadaan keras diwakili oleh huruf H. Angka dapat ditambahkan setelah dua huruf untuk menunjukkan tingkat kekerasan atau anil dari kumparan aluminium.

Besides, RAYIWELL can also supply prepainted aluminium coil or color coated aluminium coils with higher quality and competitive price.

What is color coated aluminium coil?

Aluminium berlapis warna (color coated aluminium coil), seperti namanya, adalah melakukan pelapisan permukaan dan pewarnaan pada pelat aluminium atau (aluminium coil). Biasanya aluminium berlapis warna fluorocarbon (koil aluminium berlapis warna) dan aluminium berlapis warna poliester (koil aluminium berlapis warna) banyak digunakan dalam panel aluminium-plastik, veneer aluminium, panel sarang lebah aluminium, langit-langit aluminium, permukaan atap, rongsokan, kaleng dan elektronik. Performanya sangat stabil dan tidak mudah berkarat. Setelah perlakuan khusus, permukaan dapat dicapai 30 tahun jaminan kualitas. Berat volume satuan adalah yang paling ringan di antara bahan logam. Ini adalah profil berlapis warna aluminium baru yang populer.

-

-

-