Deskripsi

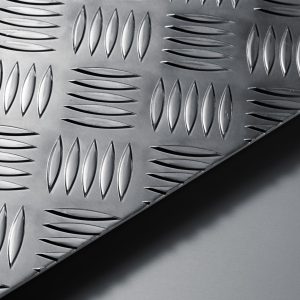

Checkered plates/tread aluminum sheet with distinct design and highly slip resistance can be easily configured into a variety of designs and patterns as per the client’s requirement. Aluminum checkered plates can be supplied in different forms of finished products including diamond plates, pelat kotak-kotak aluminium, tread plates and stair tread.

Checkered plates/tread aluminum sheet with distinct design and highly slip resistance can be easily configured into a variety of designs and patterns as per the client’s requirement. Aluminum checkered plates can be supplied in different forms of finished products including diamond plates, pelat kotak-kotak aluminium, tread plates and stair tread.

Aluminum checkered/tread plate is a product where quality and functionality meet beauty. It is used in air-conditioning, cable, exchanger, rokok, food, medicine, dekorasi, kemasan, electrical, electric products and etc.

Checkered patterns: one bar, two bar, 3 bar, 5 bar, berlian, timbul, dekoratif

Pengobatan permukaan: Mill finish, PE coated, mirror finished

Bahan: Cold rolling aluminum coil\sheet

Tipe Paduan: 1050/1060/1070/1100/1200/1350/3003/3004/3105/5005/5052/5754/5083

Ketebalan: 0.2–20.0mm

Roll Width: 500-1500mm

Melunakkan: O/H12/H22/H14/H24/H16/H26/H18

1100 aluminium Lembar: Low strength aluminum alloy has excellent corrosion resistance and satisfactory anodizing and conversion coating finishing characteristics. It is unmatched by any other commercial aluminum alloy in workability. Readily to welding, brazing, and soldering. Machinability is poor and tends to be “gummy”. Non-heat treatable. Typical applications include chemical storage, processing equipment, kitchen utensils, dan pekerjaan lembaran logam umum.

3003 aluminium Lembar: Approx. 20% higher strength than the 1100 seri, but retaining an excellent workability rating. May show some slight discoloration when anodized, but reacts well to mechanical and organic finishings. 3003 is easily welded and brazed, but solder is limited to the torch method. Suka 1100, tends to be “gummy” when machined. Non-heat treatable. Typical applications include food and chemical equipment, appliance components, truck and trailer roofing, penukar panas, and lawn furniture components.

5083 aluminium Lembar: With excellent corrosion resistance and weldability, together with high strength, this alloy was designed for welded structures requiring maximum joint strength and efficiency. Can be anodized for increased corrosion resistance, but does not lend itself to decorative applications. Not meant to be a machining alloy, but can be machined fairly well with proper preparations. Because of its relatively high magnesium content, the workability rating would only be fair. Non-heat treatable. Typical applications include large marine craft, wadah, railroad cars, structurals and elevator cars.

5454 aluminium Lembar: Excellent corrosion resistance and, unlike the other magnesium alloys, it maintains that rating when functioning in the 150-300 degrees F range where the others would be prone to stress corrosion. Not a decorative alloy but well adapted to the applied finishing processes. High strength, excellent weldability, fair formability, and poor machinability. Non-heat treatable. Typical applications include dump bodies, exhaust stacks, komponen kelautan, and chemical handling vessels.

-

-

-