Descrizione

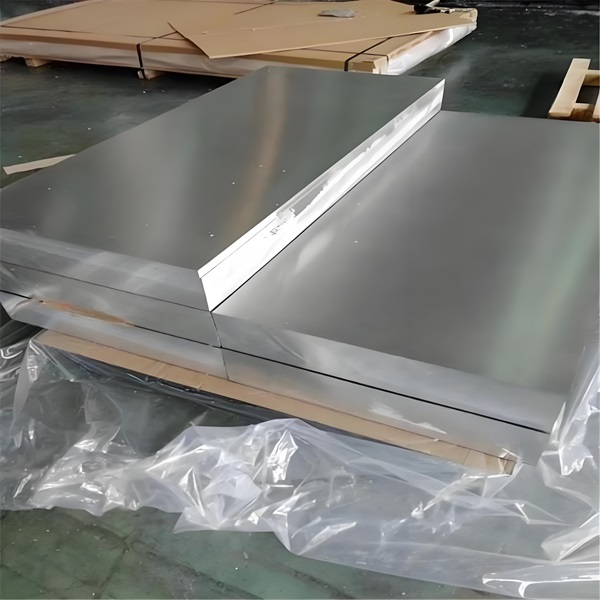

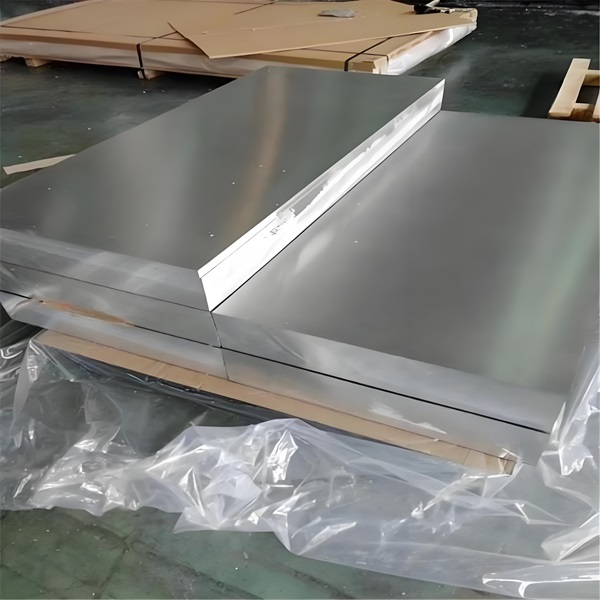

5454 aluminum sheet is widely used in ships, marine engineering, oil tankers, recipienti a pressione, automobile bodies and other fields. Its high strength and excellent corrosion resistance make it an ideal material for manufacturing ship structures, oil tank vehicle fuel tanks, chemical equipment containers and other components.

5454 lamiera di alluminio is a high-performance aluminum alloy material with many excellent properties.

5454 aluminum plate is mainly composed of alluminio, magnesium and a small amount of chromium, of which the magnesium content is approximately between 4.5% e 5.5%.

5454 aluminum sheet has high strength. The tensile strength is generally between 200-260 MPa, the compressive strength is about 180 MPa, and the yield strength is generally within the range of 140-200 MPa.

This enables it to meet engineering applications that require high material strength, such as ship structures, recipienti a pressione, eccetera.

5454 piastra di alluminio has good corrosion resistance and is highly resistant to corrosion in seawater and chloride environments.

This makes it widely used in shipbuilding, marine engineering, oil tank vehicles, chemical equipment and other fields.

The aluminum plate has good welding performance and can be connected and processed by common welding methods (such as argon arc welding, arc welding, eccetera.)

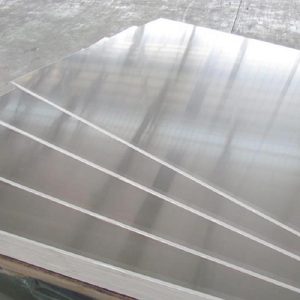

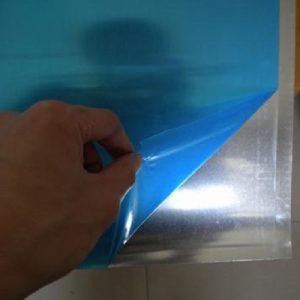

5454 aluminum sheet has good plasticity and processing performance, can be cold and hot processed, and is easy to be formed and processed into various complex shapes.

Il piastra di alluminio has good low-temperature performance and is suitable for use under low-temperature working conditions, such as cryogenic storage tanks, liquefied natural gas (LNG) serbatoi di stoccaggio, eccetera.

5454 Aluminum plate Chemistry Composition & Proprietà meccaniche & Caratteristiche:

| Element | e | Fe | con | Mn | mg | Cr | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| Standard Value | ≤0.25 | ≤0.40 | ≤0.10 | 0.50-1.0 | 2.4-3.0 | 0.05-0.20 | ≤0.20 | ≤0.25 | Resto |

| Actual Value | 0.06 | 0.28 | 0.03 | 0.87 | 2.77 | 0.09 | 0.02 | 0.02 | Resto |

Mechanical Property of 5454 H32 aluminum Plate

| Lega & Temperare | Tensile Strength Mpa | Elongation(%) | Yield Strength Mpa | Superficie |

|---|---|---|---|---|

| 5454 H32 | 250-305 | >8 | >180 | Qualified |

| 5454 il | 215-275 | >18 | 109 | Qualifie |

What are the specific applications of 5454 aluminum sheets in ship manufacturing?

L'applicazione di 5454 lastre di alluminio in ship manufacturing is specifically reflected in the following aspects:

Hull structure fabrication:

Perché 5454 aluminum sheet has high strength and good corrosion resistance, it is particularly suitable for manufacturing ship hull structures.

Per esempio, hull frames, hull plates and other parts can be manufactured using 5454 aluminum plates to ensure the solidity and durability of the hull structure.

Manufacturing of decks, bulkheads and other components:

As an important part of the ship, the deck needs to bear the weight of a large number of people and cargo, so it requires the use of high-strength materials. The high strength properties of 5454 lamiera di alluminio make it ideal for manufacturing decks.

Allo stesso tempo, since ships will encounter problems such as seawater corrosion when sailing at sea, the excellent corrosion resistance of 5454 aluminum plates can also effectively protect the deck from erosion.

Bulkheads also need to have a certain level of strength and corrosion resistance.

5454 aluminumsheets can be used to manufacture cabin partitions, inner walls and other parts to ensure the integrity and safety of the cabin.

Excellent welding performance:

A lot of welding work goes into the shipbuilding process. 5454 aluminum plates have good welding properties and can be connected and processed through common welding methods, making the hull structure stronger and more reliable.

Good formability and plasticity:

Ship manufacturing requires components of various complex shapes. 5454 aluminum plate has good formability and plasticity, and can be formed and processed into various complex shapes through cold working and hot working methods to meet various needs in ship manufacturing.

Resistance to seawater corrosion:

Ships sailing at sea for a long time will face the problem of seawater corrosion. 5454 aluminum plate has high resistance to corrosion in seawater and chloride environments, and can effectively protect ship structures from seawater erosion.

In summary, the application of 5454 aluminum plates in ship manufacturing is mainly reflected in the manufacturing of hull structures, mazzi, bulkheads and other components.

Its high strength, eccellente resistenza alla corrosione, good welding performance and formability make it an ideal choice for ships. One of the indispensable materials in manufacturing.

| piastra in alluminio technical parameters (commonly used models) | ||||

| Aluminum Plate model | Temperare | Spessore(mm) | Larghezza(mm) | Lunghezza(mm) |

| 1050 piastra in alluminio | H111, H112, H14, H18, H19, H22, H24, H26, H28 | 0.2mm-500 mm | 20mm-2630mm | personalizzato |

| 1060 piastra in alluminio | H111, H112, H14, H18, H19, H22, H24, H26, H28, eccetera. | 0.1-500mm | 20mm-2640mm | 500-10000mm |

| 1100 piastra in alluminio | il, H14, H16, H24, H22, H112, H111, H26, H12, H28, eccetera. | 0.1-500mm | 0.1-500mm | 500-16000mm |

| 2024 piastra in alluminio | T3, T4, T6, T72, T81, T351, T861, T3511, T8611, HO | 0.1mm-550mm | 700mm-2650 mm | 500-11000mm |

| 3003 piastra in alluminio | HO, H12, H14, H16, H18, H19, H22, h24, h26, H28, H112, eccetera. | 0.2mm-450mm | 50mm-2650 mm | 500-12000mm |

| 5005 piastra in alluminio | H12, H14, H16, H18, H22, h24, h26, H28, H36, H38, eccetera. | 0.2mm-600mm | 30mm-2650 mm | 500-12000mm |

| 5052 piastra in alluminio | H12, H14, H16, H18, H22, h24, h26, H28, H36, H38, eccetera. | 0.2mm-500 mm | 60mm-2650 mm | 500-10000mm |

| 5083 piastra in alluminio | H111, H114, H116, H321, H22, H24, H26, H32, H16, H12, HO, eccetera. | 0.15mm-500 mm | 30mm-2600 mm | 500-9000mm |

| 6061 piastra in alluminio | HO, F, T4, T6, T651 | 0.35mm-500 mm | 500mm-2600 mm | 600-11000mm |

| 6063 piastra in alluminio | il,T6,T651,T4 | 0.15-600mm | 500mm-2800mm | 500-16000mm |

| 7050 piastra in alluminio | HO, F, T112, T651, T6, T7451 | 1.0mm-600mm | 600mm-2500mm | 600-8000mm |

| 7075 piastra in alluminio | HO, T651, T7451, T6, eccetera | 15.0mm-600mm | 500mm-2600 mm | 600-8000mm |

-

-

-