説明

6061 そして 6063 are two common types of aluminum profiles used in various industries.

6061 aluminum profiles are known for their strength, 耐久性, 耐食性. They are often used in applications where high strength and stiffness are required, such as aerospace, 自動車, and structural engineering. 6061 aluminum profiles have excellent machinability and can be easily welded, making them a popular choice for custom fabrication.

6063 aluminum profiles, 一方, are known for their excellent finishing properties and aesthetic appeal. They are often used in applications where appearance is important, such as architectural and decorative applications. 6063 aluminum profiles have good corrosion resistance and are easy to extrude, making them a popular choice for custom extrusions.

Both 6061 そして 6063 aluminum profiles are versatile and can be used in a wide range of applications. The choice between the two depends on the specific requirements of the application, such as strength, 耐久性, and appearance.

As a leading manufacturer of advanced and highly specialized aluminum extrusions profiles. We offer a range of customized aluminum profiles, aluminum extrusions, and large structural extrusion. The aluminum profiles are ideal for constructions in machine and plant construction. Great advantage is the low weight of the profiles and a flexible connection technology.

6061 6063 アルミニウムプロファイル manufacturer RAYIWELL MFG from China. アルミニウムプロファイル can be divided into 1024, 2011, 6063, 6061, 6082, 7075 and other alloy grades of aluminum profiles, of which 6 series is the most common. The difference between different grades is that the ratio of various metal components is different, except for commonly used aluminum profiles for doors and windows In addition to architectural aluminum profiles such as 60 シリーズ, 70 シリーズ, 80 シリーズ, 90 シリーズ, and curtain wall series, there is no clear model distinction for industrial aluminum profiles, and most manufacturers process them according to the actual drawings of customers.

アルミニウムプロファイル have such surface treatment

1. Anodized aluminum

2. Electrophoretic coating of aluminum

3. Powder coated aluminum

4. Wood grain transfer aluminum

5. Fluorocarbon sprayed aluminum

6. Polished aluminum (divided into mechanical polishing and chemical polishing, among which chemical polishing has the highest cost and the most expensive price)

アルミニウムプロファイル are products born from aluminum alloys that are transformed into shaped objects through the extrusion process. Aluminum’s unique combination of physical characteristics mostly depends on this process. Aluminum extrusions are used in several fields because this metal is: Strong and stable.

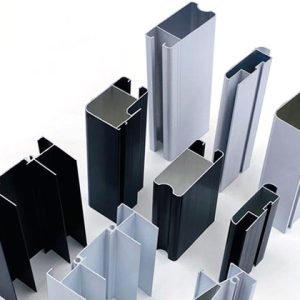

Types of aluminum profiles

- Hollow Beam.

- Square Profile.

- SD Aluminum Profile.

- RCW Profile.

- Door Section.

- Louver Profile.

- T-Section

-

合金 と 鉄 とともに マンガン マグネシウム クロム 亜鉛 チタン Impurity アル Unit 合計 6063 0.2-0.6 <0.35 <0.1 <0.1 0.45-0.9 <0.1 <0.1 <0.1 <0.05 <0.15 Surplus 6061 0.4-0.8 0.7 0.15-0.4 <0.15 0.8-1.2 0.04-0.35 <0.25 <0.15 <0.05 <0.15 Surplus 6005 0.6-0.9 <0.35 <0.1 <0.1 0.4-0.9 0.1 <0.1 <0.1 <0.05 <0.15 Surplus 6060 0.3-0.6 0.35-0.6 0.1-0.3 <0.1 <0.1 <0.15 <0.05 <0.1 <0.05 <0.15 Surplus - 典型的な用途 6061 Representative applications include aerospace fixtures, 電気器具, コミュニケーション, 自動化された機械部品にも広く使用されています, 精密加工, 金型製造, 電子機器と精密機器, SMT, PC board soldering vehicles, 等.

アルミニウム products made of aluminum and other alloying elements. It is usually processed into castings, 鍛造品, foils, プレート, ストリップ, チューブ, ロッド, profiles, 等, and then processed by cold bending, sawing, drilling, assembling, and coloring. The main metal element is aluminum, adding some alloy elements to improve the performance of aluminum

Aluminum profile extrusion is a manufacturing process that involves the creation of complex shapes and designs using aluminum as the primary material. The process involves forcing molten aluminum through a die, which is a specially designed tool that shapes the aluminum into the desired profile.

The aluminum profile extrusion process begins with the creation of a die, which is typically made from steel or some other durable material. The die is designed to produce the desired shape or profile of the finished product. Once the die is created, it is mounted on a press and heated to a temperature that is high enough to melt the aluminum.

The aluminum is then loaded into a hopper, which feeds it into the press. The press applies pressure to the molten aluminum, forcing it through the die. As the aluminum passes through the die, it is cooled and solidified, forming the desired shape or profile.

After the aluminum has been extruded, it is cut to the desired length and may undergo additional processing such as surface finishing, machining, or assembly. The resulting aluminum profiles can be used in a wide range of applications, including construction, 自動車, 航空宇宙, and consumer products.

-

-

-