기술

ASTM B221 표준으로 제조됨 6061 6063 알루미늄 그레이팅 바는 가볍습니다., 내식성, 그리고 완전히 재활용 가능. 이 제품은 산업 및 건축 응용 분야 모두에 이상적입니다..

알루미늄 바 격자, Swagged 알루미늄 바 창살이라고도 함, 무게가 가볍다, 높은 내식성을 필요로 하는 모든 하중 지지 응용 분야에 강력하고 내구성이 있습니다..

알루미늄 그레이팅 바는 다양한 베어링 바 간격으로 제공됩니다., 용도 및 하중 요구 사항에 따른 두께 및 높이. 미끄러짐 방지 기능을 추가하기 위해 매끄러운 상단 또는 톱니 모양으로 제공됩니다..

알루미늄 그레이팅 바 생산 방법?

다수의 천공 알루미늄 스트립 배열 ( 로드 바) 일정한 거리에서, 알루미늄 사각 막대를 삽입 ( 크로스로드) 배열된 로드 바 구멍에, 로드 바 사이의 크로스 로드 부분을 눌러 확장합니다., 로드 바를 조이고 고정하십시오., 그리고 교차하는 막대와 함께 격자판을 형성하십시오.

로드 바는 직사각형일 수 있습니다., I자형과 T자형. 6061 과 6063- T6 알루미늄 합금은 알루미늄 격자판에 가장 일반적으로 사용되는 재료입니다..

알루미늄 그레이팅 바 부식 방지 시 이상적인 선택입니다., 하중 용량과 기계적 강도에 영향을 주지 않는 경량 재료가 필요합니다..

ASTM B221로 제작됨, 6063 또는 6061 합금, 알류미늄 그레이팅 바는 다용도성과 내구성이 뛰어나며 주로 플랫폼 천장과 옥외 커튼월에 사용됩니다..

알루미늄 격자 막대는 저렴한 알루미늄 합금으로 만들어졌습니다., 경제적이고 실용적인. 강철 그레이팅보다 가볍고 내하력이 높습니다..

알루미늄 격자 바 안전 보호를 위한 우수한 미끄럼 방지 성능을 갖춘 매끄럽고 톱니 모양의 표면입니다.. 내부식성, 녹방지성이 우수하여 내구성이 뛰어납니다.. 다양한 애플리케이션 환경을 충족시키기 위해 다양한 사양과 스타일을 사용할 수 있습니다..

알루미늄 그레이팅 바의 주요 부분 중 하나인 크로스 바는 베어링 바 내에 완전히 고정되어 있습니다., 윗면 약간 아래. 깔끔하고 산뜻한 라인을 가지고 있어요. 거의 80% 열린 공간, 이는 공공 장소에서 일반적으로 사용되며 산업 응용 분야에서 업계에서 인정하는 표준입니다.. 미끄럼 방지가 필요한 경우, 톱니 모양의 표면을 가진 형철 모양의 직사각형 알루미늄 격자는 요청 시 제공됩니다..

크로스바는 베어링 바 내에 영구적으로 잠겨 고유한 압출 크로스바를 통해 압력을 고정합니다.. 스웨이지 플러시 탑 알루미늄 그레이팅은 지속적인 보행자 통행이 있는 지역에 향상된 보행 표면을 제공합니다.. 미끄럼 방지가 필요한 경우, 우리는 톱니 모양의 표면을 가진 스웨이지 플러시 탑 알루미늄 격자를 제공할 수 있습니다. 주로 공공장소에 사용됩니다..

일부 알루미늄 격자 막대 사양

베어링 바 크기: 1″ x 1/8″ ~ 2–1/2″ x 3/16″, 1/4″ 증분;

베어링 바 간격 (중심에서 중심으로): 1-3/16″, 15/16″, 11/16″ 및 7/16″;

크로스바 간격 (중심에서 중심으로): 4″ 또는 2″.

I자형 압출 베어링 바에 의해 지지됨, 스웨이지 I-바 알루미늄 격자는 더 가벼운 무게와 더 적은 비용으로 스웨이지 직사각형 알루미늄 격자와 동일한 하중을 전달합니다..

게다가, I바 상하단면의 줄무늬로 마찰력 증가 및 높은 미끄럼 방지 성능 제공.

사양

베어링 바 크기: 1″ x 1/4″ ~ 2–1/2″ x 1/4″(1/4″ 증분);

베어링 바 간격 (중심에서 중심으로): 1-3/16″, 15/16″, 11/16″ 및 7/16″;

크로스바 간격 (중심에서 중심으로): 4″또는 2″.

알루미늄 그레이팅 바는 부식 방지에 이상적인 선택입니다., 하중 용량과 기계적 강도에 영향을 주지 않는 경량 재료가 필요합니다..

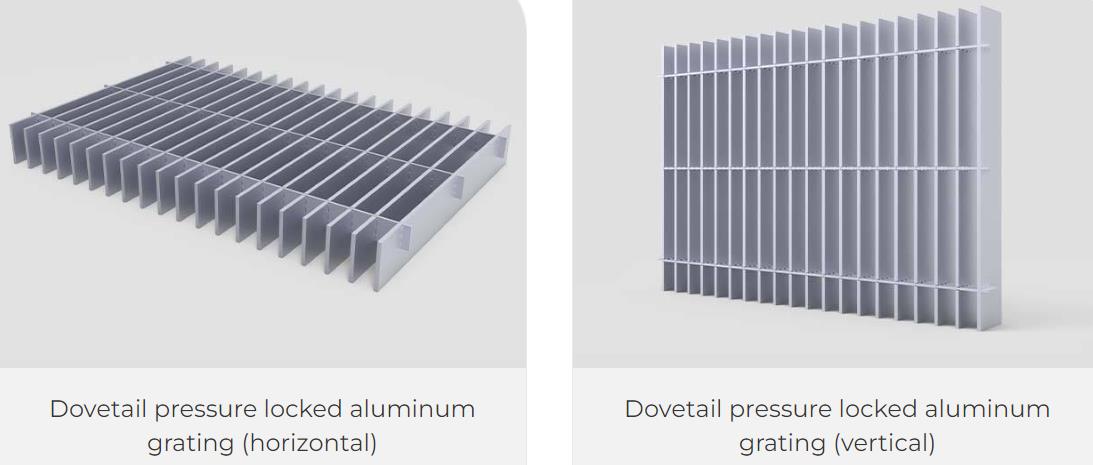

알루미늄 격자판은 일반적으로 네 가지 유형으로 제공됩니다.: 형철로 만든 직사각형 알루미늄 격자판, 스웨이지 I-바 알루미늄 격자, 스웨이지 플러시 탑 알루미늄 격자, 더브테일 압력 고정 알루미늄 격자.

우리는 냉간압연강판 등 철강재 전문 금속재료 제조 및 공급업체입니다., 아연도금강판, 알루미늄 시트, 알루미늄 격자 바, 알루미늄 천공 시트, 강철 메시, 익스펜디드 메탈, 안전바, 금속 격자판 및 와이어 메쉬.

우리는 모든 고객 및 공장과 협력하여 모든 처리 세부 사항을 제어하며 우리의 목표는 소중한 고객을 만족시키는 것입니다..

우리는 OEM 주문을 받고 있으며 고객은 대부분 북미 출신입니다., 남아메리카, 서유럽, 동유럽, 동아시아, 동남아시아, 중동, 아프리카, 오세아니아,

-

-

-