기술

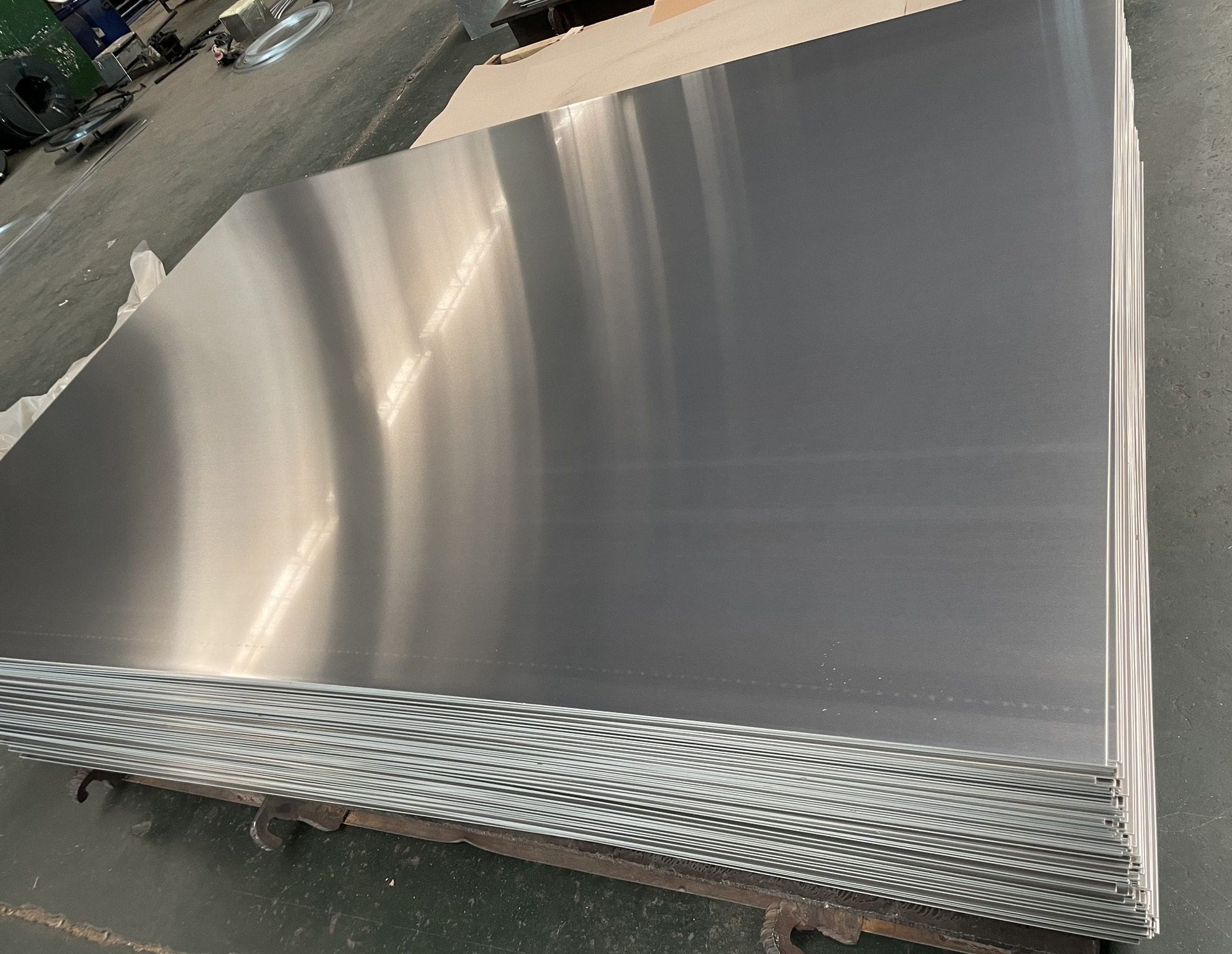

7075 aluminum sheet is a high-strength aerospace aluminum alloy that is commonly used in the manufacture of aircraft and other high-stress applications.

It has excellent strength-to-weight ratio and is resistant to stress corrosion cracking. The alloy is available in various thicknesses and sizes, and can be easily machined and formed. It is also heat treatable, which allows for further strengthening of the material.

7075 알루미늄 시트 is typically used in the construction of aircraft wings, 동체 프레임, and other structural components. It is also used in the manufacturing of high-performance sporting equipment, such as bicycle frames and rock climbing gear.

알루미늄 시트 / 플레이트 7075-T6/T651은 일반적으로 항공우주 분야에 사용됩니다., 군, 및 자동차 애플리케이션. 7075 알류미늄 가장 강한 알루미늄이다, 많은 강철의 힘으로, 알루미늄의 경량성과 내식성을 유지하면서.

| 합금 | 기질 | 두께 | 폭 |

| 7075 | T651 | 4-260mm | 1200-3800mm |

| 7075 | T7651 | 4-260mm | 1200-3800mm |

| 7075 | T7351 | 4-260mm | 1200-3800mm |

기계적 성질

| 합금 상태 | 방향 | 두께 (mm) | 인장강도 | 항복 강도 | 파괴 신장 | 표준 |

| 7075-T651 | LT | 6-260 | 570-590MPA | 495-515MPA | 10-13.5 | GB/T3880 |

| 7075-T7651 | LT | 6-102 | 550-560MPA | 480-490MPA | 10.5-12.5 | AMS4045K |

| 7075-T7351 | LT | 6-102 | 500-520MPA | 420-435MPA | 10-12.5 | AMS4078 |

알류미늄 7075 의 회원입니다 7000 시리즈, 아연을 주요 합금 성분으로 함유하고 있으며 매우 높은 강도로 잘 알려져 있습니다.. 템퍼링 처리를 하면 높은 기계적 강도를 더욱 향상시킬 수 있습니다.. 이 속성은 합금을 만듭니다 7075 항공 우주 및 방위 산업에서 매우 인기가 있습니다..

| 전형적인 기계적 성질 7075 알루미늄 판 | ||||

| 기질 | 두께

(mm) |

인장 강도

(MPA) |

항복 강도

(MPA) |

연장

(%) |

| T6 | 1~3.2 | 540 | 470 | 8 |

| T6 | 3.2~6.3 | 540 | 475 | 8 |

| T651 | 6.3~12.5 | 540 | 460 | 9 |

| T651 | 25~50 | 530 | 460 | — |

| T651 | 60~80 | 495 | 420 | — |

| T651 | 90~100 | 460 | 370 | |

그 강도는 여러 종류의 강철과 비슷합니다., 하지만 밀도가 훨씬 낮습니다. 이 합금은 고응력 응용 분야에서 강철을 대체할 수 있는 훌륭한 재료입니다.. 피로 스트레스에도 잘 견딘다., 매우 신뢰할 수 있게 만드는 것, 위에 언급된 산업에서 많이 요구되는 품질.

합금 7075 평균적인 내부식성만 제공합니다., 화학 성분에 포함된 소량의 구리로 인해 발생하는 결과. 또한 가공성이 적당하고 성형 및 용접성이 좋지 않습니다.. 이 합금의 또 다른 단점은 매우 높은 강도로 인해 다른 알루미늄 합금에 비해 상대적으로 가격이 높다는 것입니다..

레이웰 MFG or RuiYi Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Quality could full meet AMS aviation standard.

표준

Bare: AMS QQ-A-250/12, 학사 2 L95, AMS 4038, AMS 4045, AMS 4039, AMS 4049, AMS 4044, AMS 4045, AMS 4078, QQ-A-250/24, AIR 9048.690, AIR 9048.700, AIR 9048.710, AIR 9049, 기타.

AlClad: AMS QQ-A-250/13, 학사 2 L88, AMS 4046, AMS 4048, AMS 4049, QQ-A-250/18, QQ-A-250/25, QQ-A-250/26, 기타.

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

In what application scenarios can 7075 aluminum alloy not replace other materials?

7075 알루미늄 시트와 aluminum rods are important members of aluminum alloy materials. They are widely used in many fields due to their high strength, good mechanical properties, excellent corrosion resistance and wear resistance.

First of all, 7075 aluminum alloy is a high-strength heat-treatable alloy. Its strength is far greater than that of ordinary hard aluminum, and it has excellent weldability and corrosion resistance. This makes it irreplaceable in aerospace, 자동차 제조, shipbuilding and other fields.

항공우주 분야에서는, 7075 aluminum sheet plate and aluminum rods are often used to manufacture aircraft parts, such as wings, fuselages, engine casings, 기타, because they can significantly reduce the weight of aircraft and improve flight performance and fuel economy.

In automobile manufacturing, they are used to make body parts, 바퀴, suspension systems, 기타, aiming to improve the overall performance and fuel economy of the car.

둘째로, 7075 aluminum plates or aluminum sheets and aluminium rods also have good processing performance and wear resistance, which makes them useful in the fields of electronic products and sports equipment manufacturing.

In the field of electronic products, they are used to manufacture electronic equipment casings, heat sinks and other components to improve the heat dissipation efficiency and protection performance of the equipment.

In the manufacturing of sports equipment, 7075 aluminum sheets and aluminum rods are often used to make sports equipment such as hiking poles, bicycle frames, poles, and ski poles due to their lightweight and durable properties.

7075 aluminum alloy is widely used in many fields due to its high strength, wear resistance, 우수한 내식성, and good electrical and thermal conductivity.

Especially in situations where high material performance requirements are required, 7075 aluminum alloy shows its unique advantages.

구체적으로, in the aerospace field, which has extremely high requirements for the strength and corrosion resistance of the material, 7075 aluminum alloy has become an ideal choice due to its excellent performance.

예를 들면, 7075 aluminum alloy plays an irreplaceable role in the manufacturing of key components such as aircraft parts, wings, fuselages and engine casings.

Similarly, in the field of automobile manufacturing, 7075 aluminum alloy materials are often used in components such as high-strength bolts, aluminum alloy cylinders, and automobile bodies.

-

-

-