기술

Aerospace aluminum plate is an ultra-high-strength deformed aluminum alloy currently widely used in the aviation industry.

Aerospace grade aluminum refers to aluminum alloys that are specifically designed and tested for use in the aerospace industry. These alloys are chosen for their high strength, 낮은 밀도, 및 부식에 대한 내성, making them ideal for aircraft and spacecraft components

통상 알루미늄 합금과 비교해, the aluminum alloys used in aircraft have higher requirements for strength, 경도, 인성, 피로 저항, and plasticity.

Aviation aluminum alloy has good mechanical and processing properties, good plasticity after solution treatment, and good heat treatment strengthening effect. It generally has high strength and good toughness below 150°C (or even higher), making it an ideal aviation structural material.

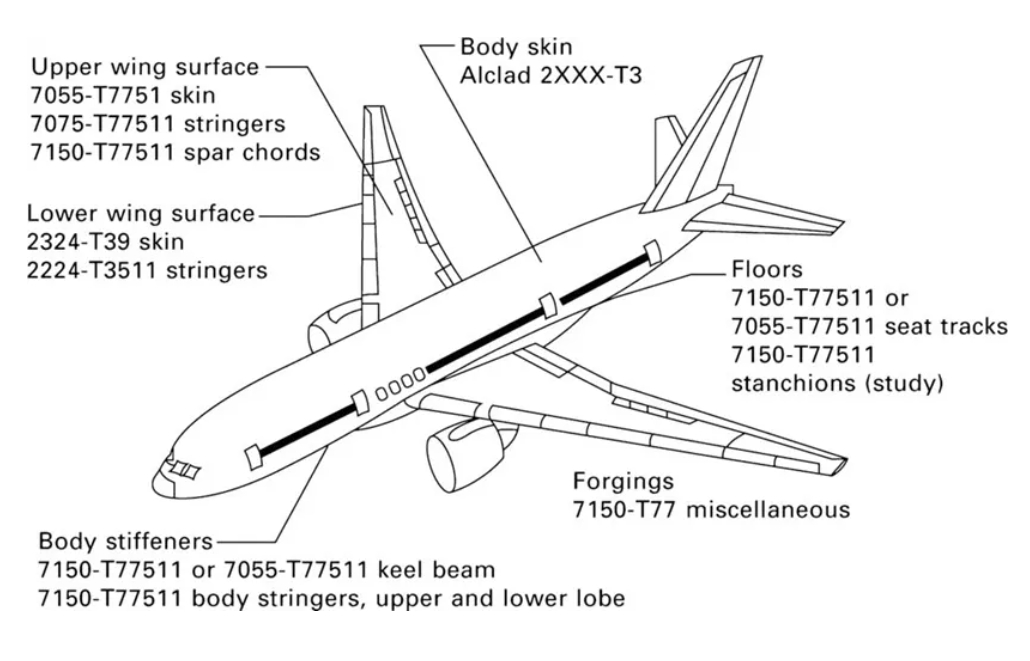

Some popular aerospace aluminum alloy are 2024, 2324, 2524 과 7050, 7055, 7075, 7475 과 6061 sometimes was used for non-structural parts.

| Item | 학년 | 기질 | 신청 |

| 1 | 2024 | 영형,T351,T851 | Fuselage structure, wing tensile component, shear web, stiff structure section |

| 2 | 2014 | T851,T351 | Fuselage machining component, bulkhead, wing skins and other structure component for high performance military aircraft |

| 3 | 2324 | T39 | Lower wing skins and wing box component for commercial aircraft |

| 4 | 7050 | T7651,T7451 | fuselage ring, frame |

| 5 | 7150 | T6151,T7751 | Upper wing skins for large commercial airplane which requires resistant to high pressure, upper wing reinforce plate and lower horizontal stabilizer panel for civil and military aircraft |

| 6 | 7055 | T7751 | Upper wing structure, horizontal stabilizer, keel beam, seat track, freight slide track |

| 7 | 7075 | T651, T7651,O,T7351 | Airplane structure component required high strength, moderate toughness and moderate corrosion resistance |

| 8 | 7475 | T651,T7351 | Fuselage skin, wing skin, wing spar, fuselage bulkhead |

항공우주 알루미늄판

Typical Products of Aluminum Sheet

| 상품명 | 합금 | 폭 | 두께 | 기질 |

| 1050 알루미늄 시트 | 1050 | 30mm-2600mm | 0.1mm-60mm | O/H |

| 1060 알루미늄 시트 | 1060 | 30mm~2600mm | 0.2mm~200mm | O/H |

| 1070 알루미늄 시트 | 1070 | 20mm-2650mm | 0.1mm-100mm | O/H |

| 1100 알루미늄 시트 | 1100 | 100mm-2600mm | 0.2mm-250mm | O/H |

| 2014 알루미늄 시트 | 2014 | 300mm-2600mm | 0.1mm-300mm | O/H/T |

| 2024 알루미늄 시트 | 2024 | 300mm-2650mm | 0.3mm-300mm | O/H/T/F |

| 2A12 Aluminum Sheet | 2A12 | 100mm-2650mm | 0.1mm-300mm | O/H/T/F |

| 3003 알루미늄 시트 | 3003 | 100mm-2650mm | 0.1mm-500mm | F/O/H |

| 3004 알루미늄 시트 | 3004 | 100mm-2650mm | 0.2mm-400mm | F/O/H |

| 3005 알루미늄 시트 | 3005 | 100mm-2650mm | 0.2mm-400mm | F/O/H |

| 3104 알루미늄 시트 | 3104 | 100mm-2650mm | 0.1mm-400mm | F/O/H |

| 3105 알루미늄 시트 | 3105 | 20mm-2650mm | 0.2mm-400mm | F/O/H |

| 3A21 Aluminum Sheet | 3A21 | 20mm-2650mm | 0.2mm-400mm | F/O/H |

| 5005 알루미늄 시트 | 5005 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5052 알루미늄 시트 | 5052 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5083 알루미늄 시트 | 5083 | 20mm-3000mm | 0.4mm-500mm | F/O/H |

| 5086 알루미늄 시트 | 5086 | 20mm-2650mm | 0.5mm-500mm | F/O/H |

| 5182 알루미늄 시트 | 5182 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5454 알루미늄 시트 | 5454 | 20mm-2650mm | 0.4mm-500mm | F/O/H |

| 5754 알루미늄 시트 | 5754 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5A03 Aluminum Sheet | 5A03 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5A06 Aluminum Sheet | 5A06 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5A02 Aluminum Sheet | 5A02 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5252 알루미늄 시트 | 5252 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 5A05 Aluminum Sheet | 5A05 | 20mm-2650mm | 0.1mm-500mm | F/O/H |

| 6005 알루미늄 시트 | 6005 | 20mm-2650mm | 0.2mm-500mm | F/O/H/T |

| 6060 알루미늄 시트 | 6060 | 20mm-2650mm | 0.2mm-500mm | F/O/H/T |

| 6061 알루미늄 시트 | 6061 | 20mm-2650mm | 0.2mm-500mm | F/O/H/T |

| 6063 알루미늄 시트 | 6063 | 20mm-2650mm | 0.2mm-500mm | F/O/H/T |

| 6082 알루미늄 시트 | 6082 | 20mm-2650mm | 0.2mm-500mm | F/O/H/T |

| 6101 알루미늄 시트 | 6101 | 20mm-2650mm | 0.2mm-500mm | F/O/H/T |

| 6005-A Aluminum Sheet | 6005에이 | 20mm-2650mm | 0.2mm-500mm | F/O/H/T |

| 7075 알루미늄 시트 | 7075 | 20mm-2550mm | 0.8mm-500mm | F/O/H/T |

| 7005 알루미늄 시트 | 7005 | 20mm-2500mm | 0.8mm-500mm | F/O/H/T |

| 7050 알루미늄 시트 | 7050 | 20mm-2500mm | 0.8mm-500mm | F/O/H/T |

| 7A09 Aluminum Sheet | 7A09 | 20mm-2500mm | 0.8mm-500mm | F/O/H/T |

| 7A04 Aluminum Sheet | 7A04 | 20mm-2500mm | 0.8mm-500mm | F/T/H |

| 8011 Aluminum Sheet/Coil | 8011 | 10mm-2500mm | 0.1mm-20mm |

Aluminum alloys are widely used in launch vehicles in the aerospace field. The main grades are 7075, 20X4, 2219, 기타. The engine device, main components, rotary table, remote control parts, 기타. are mainly aluminum alloy 7075. 예를 들면, the liquid oxygen tank is mainly 2219. 20X4 is mainly used for satellite streamlined outer covers and temperature control valve components. 게다가, the frame of the manned aircraft is made of 2024 과 7075 aluminum alloys because these two aluminum alloys have high strength, light weight and thin thickness. Aluminum alloy sheets are also frequently used in these objects, such as protective panels, safety devices, 프로펠러, 기타.

How is Aerospace Aluminum Plate Different from Regular Aluminum?

Aerospace aluminum plate is different from regular aluminum in several ways:

1. 합금 조성: Aerospace aluminum plate is typically made from high-strength aluminum alloys that are specifically designed for aerospace applications. These alloys usually have a higher content of elements like copper, 아연, 마그네슘, 및 망간, which enhance the strength and durability of the material. Regular aluminum, 다른 한편으로는, may have a lower alloy content and is often used for general-purpose applications.

2. Strength and toughness: Aerospace aluminum plate is engineered to have superior strength and toughness compared to regular aluminum. It undergoes various heat treatment processes to enhance its mechanical properties, making it capable of withstanding high stress and loads experienced in aerospace applications. Regular aluminum may not possess the same level of strength and toughness.

3. 무게: Aerospace aluminum plate is lightweight compared to regular aluminum. The aerospace industry emphasizes the importance of reducing weight to improve fuel efficiency and increase payload capacity. 따라서, aerospace aluminum plate is designed to be lightweight while maintaining its structural integrity. Regular aluminum may have a higher weight due to lower strength requirements.

4. Quality control: Aerospace aluminum plate undergoes stringent quality control processes to ensure its performance and reliability. It needs to meet various industry standards and specifications, such as those set by the International Aerospace Quality Group (IAQG). Regular aluminum may not be subjected to the same level of quality control measures.

5. 비용: Aerospace aluminum plate is generally more expensive than regular aluminum due to its specialized composition, manufacturing processes, and quality requirements. The aerospace industry demands high-performance materials, which often come at a higher cost. Regular aluminum, being more widely used and less specialized, tends to be more affordable.

-

-

-