apibūdinimas

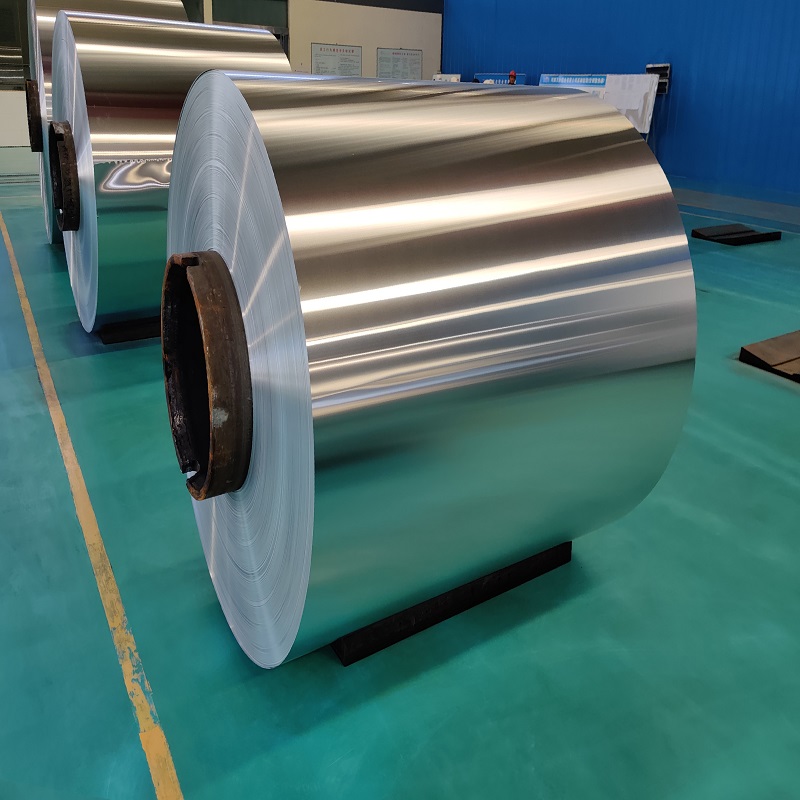

6061 aluminum coil made in China is a heat-treated reinforced alloy sheet with good formability, suvirinamumas, machinability, and moderate strength, which can maintain good operability after annealing.

Magnesium-aluminum 6061-T651 is the main alloy of the 6-series alloy, and it is a high-quality aluminum alloy product that has undergone heat treatment and pre-stretching. Jis pasižymi puikiomis savybėmis, tokiomis kaip lengvai dažanti plėvelė ir puikus oksidacijos efektas.

6061 aliuminio ritė is Widely used in various industrial structural parts that require a certain strength and high corrosion resistance, pavyzdžiui, gamybos sunkvežimiai, bokštiniai pastatai, laivai, tramvajų, railway vehicles.

6061 aliuminio lydinys is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2XXX series or 7XXX series, its magnesium and silicon alloys have many characteristics, excellent processing performance and excellent welding characteristics. And electroplating, geras atsparumas korozijai, didelis tvirtumas ir po apdorojimo nėra deformacijos, dense material without defects and easy to polish, easy to color film, excellent oxidation effect and other excellent characteristics.

The main alloying elements of 6061 aliuminio lydiniai yra magnis ir silicis, and form Mg2Si. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; there is still a small amount of conductive material. copper to offset the adverse effects of titanium and iron on electrical conductivity; zirconium or titanium can refine grains and control recrystallization; in order to improve machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial aging hardening function. Pagrindiniai legiravimo elementai 6061 aliuminio lydiniai yra magnis ir silicis, kurios yra vidutinio stiprumo, geras atsparumas korozijai, suvirinamumas, ir geras oksidacinis poveikis.

The general purpose 6061 Aliuminio ritė is heat treatable, ASTM B209, and is easy to weld and machine, ASTM B209. 6061 Aluminum coil and aluminum Plate are ideal for structural framing, ASTM B209, ASTM B209, lėktuvas, marine and automotive parts, ir tt

Because 6061 aluminium alloy is easy to extrude, it can provide a variety of product forms such as sheet, strip, plokštė, strypas, kaltiniai, vamzdžiai, vamzdžiai, laidai, extruded parts and structural shapes. aliuminis 6061 has good corrosion resistance, mechanical properties, formavimo savybėmis, suvirinamumas, and machinability.

It belongs to 6000 serija (Al-Mg-Si) alloy aluminum sheet and has good weldability. Tuo pačiu metu, 6061 aluminum coil sheet has excellent aluminum-magnesium composition ratio and strong corrosion resistance. The hardness is 95HB (Brinell), easy to process and form, non-stick knife

6061 Aluminium Aging 6061 aliuminio lydinio lakštai, plokštės, rolled or cold-rolled wire, strypai, barai, and drawn tubing are aged to a metal temperature of 160 °C (320 °F) and maintaining it for 18h. Extruded rods, strypai, shapes and tubes; dies and hand forgings, rolled rings are aged to a metal temperature of 175 °C (345 °F) and held for 8 valandos

nuotaika: T1,T2,T3, T4, T6, T651

storis:0.2-350mm

plotis:30-2600mm

ilgis:200-11000mm

Motinos ritė: CC arba DC

svoris: Apie 2 mt vienam padėklui bendram dydžiui

MOQ: 5-10tonų vienam dydžiui

Apsauga: popieriaus tarpsluoksnis, balta plėvelė, mėlyna plėvelė, juodai balta plėvelė, mikro surišta plėvelė, pagal jūsų reikalavimą.

Paviršius: švarus ir lygus, jokios ryškios dėmės, korozija, Alyva, su grioveliu, ir tt.

Standartinis produktas: GBT3880, JIS4000, EN485, ASTM-B209, EN573

Pristatymo laikas: apie 30 dienų nuo indėlio gavimo

mokėjimas: T/T, L/C matant

Prekybos sąlygos: FOB, CIF, CFR

The 6061 alloy is one of the most common for extrusion, but you may be considering other options for your particular application. Below are some other common alloys that are often considered as alternatives.

6061 ir 6063 are the two most popular extrusion alloys. 6063 aluminum occupies the number one spot and 6061 occupies spot number two. As alloys in the 6000 serija, they both have magnesium and silicon as their primary alloying elements. taip, they have many similar properties. 6061 offers higher strength, tačiau. As such, it is often used for more structural applications. 6063, iš kitos pusės, is used for applications such as railing or trim, langai, and doors, due to its better appearance and corrosion resistance.

Kaip 6061, 5052 aluminum has magnesium as a primary alloying element. In the case of 5052, it is the only primary alloying element. 6061 has silicon as well. One of the key benefits of this alloy is its high level of weldability compared to other alloys. For projects where weldability is key, it is worth considering. One downside to 5052, though, is that it is not heat treatable. It is good for a variety of welding applications and it works well in marine applications due to its high corrosion resistance.

Primarily used in aerospace applications, the 2024 alloy is known for high strength. Its main alloying element is copper, and although it is strong and has good fatigue resistance, it is less machinable and more difficult to weld than 6061. It also offers poor corrosion resistance and is often used in wing and fuselage structures which come under high tension.

A member of the 6000 serija, 6061 aluminum’s main alloying elements are magnesium and silicon, and it’s a great example of a jack of all trades. The alloy is somewhat universal, seeing some exposure in structural and building products as well as the aerospace and recreation industries.

lydinys 6061 displays good tensile strength, which can be improved by temper treatment, and good corrosion resistance, suvirinamumas, and workability. Its workability makes it the right choice for many extrusion projects, as it is easy to form.

The alloy is widely available at a relatively low cost and is a great option to produce varied and precise components in different shapes. Although alloy 6061 doesn’t rank first in any aluminum properties tier list, it’s a great and reliable all-around aluminum alloy to work with.

-

-

-