Penerangan

6061 dan 6063 are two common types of aluminum profiles used in various industries.

6061 aluminum profiles are known for their strength, ketahanan, and corrosion resistance. They are often used in applications where high strength and stiffness are required, such as aerospace, automotif, and structural engineering. 6061 aluminum profiles have excellent machinability and can be easily welded, making them a popular choice for custom fabrication.

6063 aluminum profiles, selain itu, are known for their excellent finishing properties and aesthetic appeal. They are often used in applications where appearance is important, such as architectural and decorative applications. 6063 aluminum profiles have good corrosion resistance and are easy to extrude, making them a popular choice for custom extrusions.

Both 6061 dan 6063 aluminum profiles are versatile and can be used in a wide range of applications. The choice between the two depends on the specific requirements of the application, such as strength, ketahanan, and appearance.

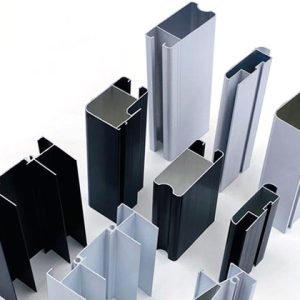

As a leading manufacturer of advanced and highly specialized aluminum extrusions profiles. Kami menawarkan rangkaian profil aluminium yang disesuaikan, penyemperitan aluminium, dan penyemperitan struktur yang besar. Profil aluminium sesuai untuk pembinaan dalam pembinaan mesin dan loji. Kelebihan besar ialah berat profil yang rendah dan teknologi sambungan yang fleksibel.

6061 6063 Profil aluminium pengilang RAYIWELL MFG dari China. Profil aluminium can be divided into 1024, 2011, 6063, 6061, 6082, 7075 dan gred aloi lain bagi profil aluminium, yang mana 6 siri adalah yang paling biasa. Perbezaan antara gred yang berbeza ialah nisbah pelbagai komponen logam adalah berbeza, except for commonly used aluminum profiles for doors and windows In addition to architectural aluminum profiles such as 60 siri, 70 siri, 80 siri, 90 siri, dan siri dinding tirai, tiada perbezaan model yang jelas untuk profil aluminium perindustrian, dan kebanyakan pengeluar memprosesnya mengikut lukisan sebenar pelanggan.

Profil aluminium mempunyai rawatan permukaan sedemikian

1. Aluminium anodized

2. Salutan elektroforetik aluminium

3. Aluminium bersalut serbuk

4. Aluminium pemindahan bijirin kayu

5. Aluminium yang disembur fluorokarbon

6. Aluminium yang digilap (dibahagikan kepada penggilap mekanikal dan penggilap kimia, antaranya penggilap kimia mempunyai kos tertinggi dan harga paling mahal)

Profil aluminium are products born from aluminum alloys that are transformed into shaped objects through the extrusion process. Gabungan unik ciri fizikal aluminium kebanyakannya bergantung pada proses ini. Penyemperitan aluminium digunakan dalam beberapa bidang kerana logam ini adalah: Kuat dan stabil.

Jenis profil aluminium

- Rasuk Berongga.

- Profil Segi Empat.

- Profil Aluminium SD.

- Profil RCW.

- Bahagian Pintu.

- Profil Louver.

- Bahagian-T

-

aloi dan Fe dengan Mn mg Cr Zn Ti Impurity Al Unit Total 6063 0.2-0.6 <0.35 <0.1 <0.1 0.45-0.9 <0.1 <0.1 <0.1 <0.05 <0.15 Surplus 6061 0.4-0.8 0.7 0.15-0.4 <0.15 0.8-1.2 0.04-0.35 <0.25 <0.15 <0.05 <0.15 Surplus 6005 0.6-0.9 <0.35 <0.1 <0.1 0.4-0.9 0.1 <0.1 <0.1 <0.05 <0.15 Surplus 6060 0.3-0.6 0.35-0.6 0.1-0.3 <0.1 <0.1 <0.15 <0.05 <0.1 <0.05 <0.15 Surplus - Typical uses of 6061 Representative applications include aerospace fixtures, electrical fixtures, communications, and are also widely used in automated mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board soldering vehicles, dan lain-lain.

aluminium products made of aluminum and other alloying elements. Ia biasanya diproses menjadi tuangan, penempaan, kerajang, plat, jalur, tiub, batang, profil, dan lain-lain., dan kemudian diproses dengan lenturan sejuk, menggergaji, menggerudi, berhimpun, dan mewarna. Unsur logam utama ialah aluminium, menambah beberapa unsur aloi untuk meningkatkan prestasi aluminium

Aluminum profile extrusion is a manufacturing process that involves the creation of complex shapes and designs using aluminum as the primary material. The process involves forcing molten aluminum through a die, which is a specially designed tool that shapes the aluminum into the desired profile.

The aluminum profile extrusion process begins with the creation of a die, which is typically made from steel or some other durable material. The die is designed to produce the desired shape or profile of the finished product. Once the die is created, it is mounted on a press and heated to a temperature that is high enough to melt the aluminum.

The aluminum is then loaded into a hopper, which feeds it into the press. The press applies pressure to the molten aluminum, forcing it through the die. As the aluminum passes through the die, it is cooled and solidified, forming the desired shape or profile.

After the aluminum has been extruded, it is cut to the desired length and may undergo additional processing such as surface finishing, machining, or assembly. The resulting aluminum profiles can be used in a wide range of applications, including construction, automotif, aeroangkasa, and consumer products.

-

-

-