Penerangan

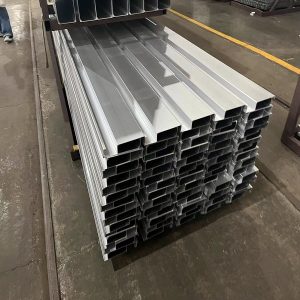

The heat sink Aluminum profiles are specially designed structures made from aluminum that are used to dissipate heat from electronic components. They are commonly used in computers, LED lights, power amplifiers, and other devices that generate a significant amount of heat.

Profil aluminium sesuai untuk pembinaan dalam pembinaan mesin dan loji. Kelebihan besar ialah berat profil yang rendah dan teknologi sambungan yang fleksibel.

Aluminum heat sink profiles manufacturer RAYIWELL MFG / TOP Metal Manufacture have advanced experiences with customized aluminum heat sink profiles, aluminum profiles, penyemperitan aluminium, dan penyemperitan struktur yang besar.

The aluminum heat sink profiles refers to its shape and design, which can vary depending on the specific application and thermal requirements.

The aluminum heat sink profiles are made by extruding aluminum through a die to create a specific shape. They typically have fins or ridges on the surface to increase the surface area, allowing for better heat dissipation.

Aluminum heat sink profiles are widely used in various industries and applications for their excellent thermal conductivity and lightweight properties. Some of the common applications of aluminum heat sinks include:

1. Electronics: Aluminum heat sink profiles are extensively used in electronic devices such as computers, laptops, smartphones, and LED lights to dissipate heat generated by electronic components like processors, graphic cards, and power transistors.

2. Power electronics: Aluminum Heat sink profiles made of aluminum are used in power electronic devices such as inverters, power supplies, and motor drives to prevent overheating and ensure optimal performance and reliability.

3. Automotive industry: Aluminum heat sink profiles are employed in automotive applications like electric vehicles, hybrid vehicles, and internal combustion engines to manage the heat generated by various components such as batteries, power electronics, and engine blocks.

4. Industrial machinery: aluminum heat profiles are used in industrial machinery and equipment, including CNC machines, laser cutting machines, and power generators, to dissipate heat generated during operation and prevent damage to critical components.

5. Lighting industry: Aluminum heat sink profiles are widely used in LED lighting fixtures to dissipate heat generated by the LED chips, ensuring longer lifespan and maintaining optimal performance.

6. Telecommunications: Heat sinks made of aluminum are used in telecommunications equipment such as routers, switches, and base stations to dissipate heat generated by high-power transmitters and processors.

7. Aerospace and aviation: Aluminum heat sink profiles find application in aerospace and aviation industries, where they are used in avionics, satellite systems, and aircraft engines to manage heat generated by electronic components and power systems.

8. Medical equipment: Aluminum heat sinks are used in medical equipment such as MRI machines, X-ray machines, and laser systems to dissipate heat generated by high-power components and ensure reliable and safe operation.

Keseluruhannya, the application of aluminum heat sinks is crucial in various industries to maintain the optimal temperature of electronic components, improve energy efficiency, and prevent overheating-related failures.

In-depth analysis of aluminum radiator profiles Aluminum radiator profiles are a common and widely used radiator material.

It is made of high-purity aluminum alloy, which is lightweight, has good thermal conductivity and has strong plasticity.

Aluminum radiator profiles are widely used in various electronic equipment, kereta, industrial equipment and other fields to provide heat dissipation and protect equipment from overheating damage.

Industrial aluminium extrusion profiles are also called industrial aluminum extrusions and industrial aluminum alloy profiles.

Industrial aluminium profiles are alloy materials with aluminum as the main component. Aluminum rods are hot-melted and extruded to obtain aluminum materials with different cross-sectional shapes, but The proportion of the added alloy is different, and the mechanical properties and application fields of the produced industrial aluminum profiles are also different.

Fields of application Generally speaking, industrial aluminum profiles refer to all aluminum profiles except for building doors and windows, dinding langsir, interior and exterior decoration, and aluminum profiles for building structures.

Aluminum products made of aluminium and other alloying elements. Ia biasanya diproses menjadi tuangan, penempaan, kerajang, plat, jalur, tiub, batang, profil, dan lain-lain., dan kemudian diproses dengan lenturan sejuk, menggergaji, menggerudi, berhimpun, dan mewarna. Unsur logam utama ialah aluminium, menambah beberapa unsur aloi untuk meningkatkan prestasi aluminium

Elektroforesis profil aluminium

1. Rintangan kakisan yang kuat: permukaan mempunyai prestasi anti-karat yang tinggi, yang berkesan boleh menghalang asid, kakisan alkali dan garam. Ia adalah varieti terbaik untuk anti-karat mortar bangunan.

2. Hayat prestasi yang memuaskan, walaupun dalam persekitaran yang keras dan keras, ia boleh memastikan jangka hayat lebih daripada 50 tahun tanpa kakisan, penuaan, pudar, atau jatuh.

3. Rasa tangan licin dan halus, dan penampilannya cerah dan cantik. Hebat. Pelbagai warna boleh didapati.

4. Kekerasan filem cat adalah tinggi. Ia boleh menahan kekerasan pen aluminium melebihi 3H untuk lukisan dan ukiran

Profil aluminium pengoksidaan

Substrat digunakan sebagai anod, diletakkan dalam elektrolit untuk elektrolisis, dan filem oksida pelindung dibentuk secara buatan pada permukaan substrat untuk membentuk bahan alumina.

Ciri utama bahan alumina:

1. Ia mempunyai rintangan haus yang kuat, rintangan cuaca dan rintangan kakisan.

2. Ia boleh membentuk pelbagai warna pada permukaan substrat, yang paling sesuai untuk keperluan anda.

3. Kekerasan yang kuat, sesuai untuk pengeluaran pelbagai bahan binaan dan perindustrian.

(1) Aluminium untuk pembinaan

1. bumbung: 1050, 1100, 3105, 5052

2. Kediaman, gudang, kilang, pejabat, kedai: 1050, 1100, 3003, 5005, 5052, 6063 papan, profil

3. Papan lantai, dinding dalam, petak: 1100, 5005, 6063 papan, profil

4. Lubang pengudaraan, susur tangan, penerang: 1080, 5052, 5N01, 6063 profil, plat

5. pintu: 1050, 1100, 5005, 5052, 6063 papan dan profil

6. Pengatup: 5052, 5182 papan

7. Rel tingkap langsir: 5052, 6063 pinggan berbentuk, plat

8. Pintu kekisi dan daun pintu: 5052, 6063 papan, bentuk, paip

9. Tingkap astringen: 1100, 5052, 6063 bentuk, plat

10. Bingkai tingkap: 6063 profil

11. dinding: 5052, 6061, 6N01, 6063, 5056 papan, profil, wayar

12. Balkoni: 5052, 6063, 6profil N01

(2) Aluminium untuk kegunaan industri

1. Pengenalan laluan: 5052, 6061, 6063 plat dan profil

2. Pagar tinggi untuk jalan persendirian: 6061, 6N01, 6063, 5083 bentuk, plat, paip

3. Lajur pencahayaan: 5052, 5083, 6063 tiub

4. Jambatan, jambatan langkah demi langkah: 5083, 6061, 6N01, 7003, 7profil N01, plat, kepingan tiub, profil

5. Dinding penebat bunyi 1100, 5052, 6063 bentuk, plat, tiub

6. Struktur kecil yang menonjol: 2014, 5052, 5083, 6061 6N01, 6063, 7003, 7profil N01, plat, paip

7. Troli: 5083, 6101, 6063, 7003 profil

8. Struktur atas talian yang tidak berkaitan: 5052, 5083, 6061, 6N01, 7003, 7bentuk N01, plat, paip

9. Plat belakang untuk kejuruteraan pertanian: 7N01, 7003 profil

10. Perancah (untuk pembinaan dan pembinaan kapal): 5052, 6N01, 6063 plat dan profil

11. Gerbang: 5052, 5083 papan, bentuk

12. Meliputi: 6063 profil

(3) Bahan aluminium untuk komponen mesin elektrik

1. Tujuan hiasan biasa: 1080, 1070, 1050, 6063 papan dan profil

2. Tempat duduk atas elektrik yang kuat dan papan penyelenggaraan: 1100, 5052, 5082 papan

3. Kotak penyelenggaraan, kotak kapasitor: 1100, 1050 papan

4. Kapasitor elektrik: 1085, 1070, 1050 kerajang

5. Bateri boleh ubah: 1100, 1050, 1070, 5052 plat, kerajang

6. galas: 2011, 2017 batang, tiub

7. Bingkai pembesar suara: 1100, 5052 papan

8. Tombol: 2011, 5052, 5056, 6063, 6262 batang, plat

9. Terima kasih kerana menutup papan: 1100, 5052 papan

10. Jantung Logam Zao Han Light Cannon: 3004 Papan

11. Jantung logam bercahaya: 1100 plat

12. Pemanas sarung: 1100, 3003, 6063 tiub

13. Tiub konduktif: 1050, 3003, 6063 bentuk, tiub

14. Pengumpul haba semikonduktor: 1050, 6063 plat, bentuk

15. wayar tanah TV: 1100, 3003, 6063 tiub

16. kabinet TV: 5052 papan

17. silinder VTR: 2018, 2618 batang

18. Panduan tali pinggang VTR: 5052, 5056, 6063, 7003 bentuk, tiub

19. Plat persegi magnetik: 5086 plat

20. Drum magnet: 2025, 2218, 4032 produk palsu

21. Kawat tanah radar dan antena hidangan: 6061, 6N01, 6063 profil

22. Rangka motor: 1050, 6063 plat, bentuk

23. Gegelung Pusing: 1060, 6101 profil, 2024, 7profil N01, 1060, 6101, 6061, 6063 profil, plat, tiub

24. Salutan kabel: 1050 tiub, plat

25. Bilah kipas pengudaraan: 1100, 3003, 5052 papan

26. Periuk elektrik: 1100, 3003, 3004, 5plat N01

27. Lembaran sejuk poli: 1100, 1200, 1050, 3003, 7072 plat

28. Drum mesin penyalin: 1050, 3003, 6063 tiub

Profil aluminium yang diekstrusi (profil penyemperitan aluminium ) is used for a wide range of purposes, including components of the International Space Station. With its pliability, lightweight and strength, extruded aluminum offers endless application opportunities in Architecture & Construction, Energy, Pengangkutan & Vehicles, Electronics, Industrial Design and General Engineering.

These diverse applications are possible due to the advantageous attributes of aluminum, its particular blend of strength and ductility to its conductivity, its non-magnetic properties and its ability to be recycled repeatedly without loss of integrity. All of these capabilities make extruded aluminum a viable and adaptable solution for an growing number of manufacturing needs.

Industrial aluminium extrusion profiles are widely used and highly versatile. It is famous for its environmental protection, convenient assembly and disassembly, time saving and long service life.

There are many varieties and complete specifications of industrial aluminum profiles, which are suitable for various types of mechanical devices; no welding is required, the size is convenient to adjust, and the structure is easy to change; the dimensional tolerance is strict and the surface finish is high; the assembly work is convenient and fast, and the productivity is high; the surface is anodized Treatment, anti karat, spray-free, beautiful and generous, can increase the added value of products.

Applicable scope of application: production lines, assembly line operation workbenches, office partitions, screens, industrial fences and various frames, tempat paparan, shelves, mechanical dustproof seal covers, dan lain-lain.

-

-

-