Beschrijving

6061 aluminum plate is a heat-treated reinforced alloy sheet with good formability, lasbaarheid, machinability, and moderate strength, which can maintain good operability after annealing.

Magnesium-aluminum 6061-T651 is the main alloy of the 6-series alloy, and it is a high-quality aluminum alloy product that has undergone heat treatment and pre-stretching. Het heeft uitstekende eigenschappen zoals een gemakkelijke kleurfilm en een uitstekend oxidatie-effect.

6061 aluminium plaat is Widely used in various industrial structural parts that require a certain strength and high corrosion resistance, zoals het maken van vrachtwagens, toren gebouwen, schepen, trams, railway vehicles.

6061 aluminium profiel is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Hoewel de sterkte niet kan worden vergeleken met 2xxx -serie of 7xxx -serie, De magnesium- en siliciumlegeringen hebben veel kenmerken, Uitstekende verwerkingsprestaties en uitstekende laskenmerken. En elektropleren, goede weerstand tegen corrosie, hoge taaiheid en geen vervorming na verwerking, dicht materiaal zonder defecten en gemakkelijk te polijsten, Makkelijk te kleuren film, Uitstekend oxidatie -effect en andere uitstekende kenmerken.

The main alloying elements of 6061 aluminiumlegering zijn magnesium en silicium, and form Mg2Si. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; there is still a small amount of conductive material. copper to offset the adverse effects of titanium and iron on electrical conductivity; zirconium or titanium can refine grains and control recrystallization; in order to improve machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial aging hardening function. De belangrijkste legeringselementen in 6061 aluminiumlegering zijn magnesium en silicium, die een gemiddelde sterkte hebben, goede weerstand tegen corrosie, lasbaarheid, en goed oxidatie-effect.

The general purpose 6061 Aluminium Plate is heat treatable, bestand tegen scheuren als gevolg van stress, and is easy to weld and machine, maar beperkt op vormbaarheid.

6061 Aluminum plate is ideal for structural framing, basis platen, gussetts, vliegtuig, marine and automotive parts, enz

Because 6061 aluminium alloy is easy to extrude, it can provide a variety of product forms such as sheet, strip, bord, rod, smeedstukken, tubes, pijpen, wires, extruded parts and structural shapes. Aluminium 6061 heeft een goede corrosieweerstand;, mechanical properties, vervormbaarheid, lasbaarheid, and machinability.

It belongs to 6000 serie (Al-Mg-Si) alloy aluminum sheet and has good weldability. Tegelijkertijd, 6061 aluminum coil sheet has excellent aluminum-magnesium composition ratio and strong corrosion resistance. The hardness is 95HB (Brinell), easy to process and form, non-stick knife

6061 Aluminium Aging 6061 platen van aluminiumlegering, platen, rolled or cold-rolled wire, staven, bars, and drawn tubing are aged to a metal temperature of 160 °C (320 °F) and maintaining it for 18h. Extruded rods, staven, shapes and tubes; dies and hand forgings, rolled rings are aged to a metal temperature of 175 °C (345 °F) and held for 8 uur

Temperen: T1,T2,T3, T4, T6, T651

Dikte:0.2-350mm

Breedte:30-2600mm

Lengte:200-11000mm

moeder spoel: CC of DC

Gewicht: Ongeveer 2mt per pallet voor algemene maat

MOQ: 5-10ton per maat

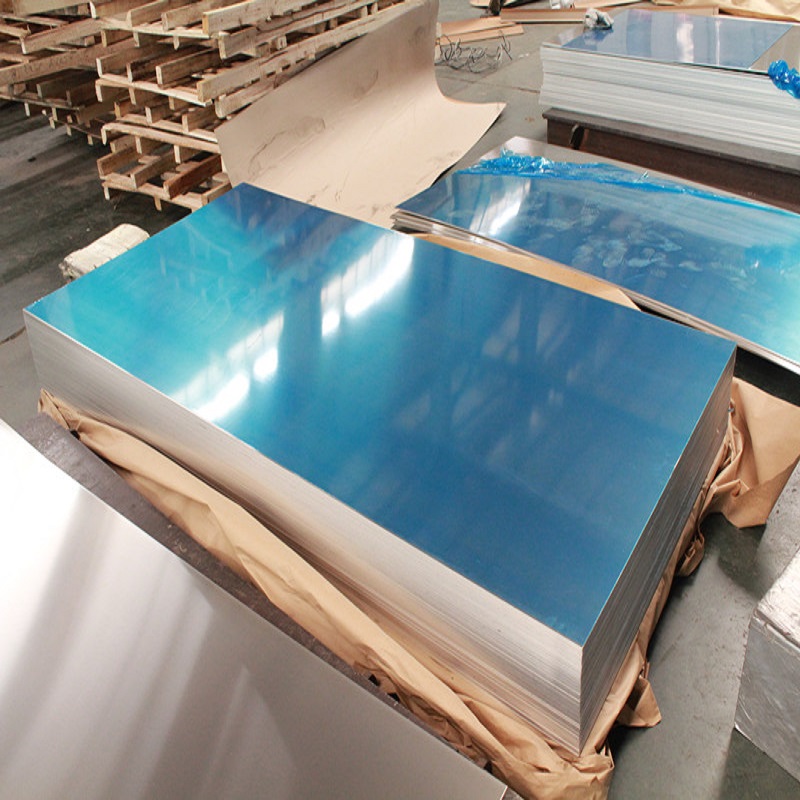

Bescherming: papier tussenlaag, witte film, blauwe film, zwart-wit film, microgebonden film, volgens uw vereiste.

Oppervlakte: schoon en glad, geen heldere vlek, corrosie, olie-, sleuven, enz.

Standaard product: GBT3880, JIS4000, EN485, ASTM-B209, EN573

Tijd om te bezorgen: ongeveer 30 dagen na ontvangst van de aanbetaling;

Betaling: T/T, L/C op zicht

Handelsvoorwaarden:: FOB, CIF, CFR

De 6061 alloy is one of the most common for extrusion, but you may be considering other options for your particular application. Below are some other common alloys that are often considered as alternatives.

6061 en 6063 are the two most popular extrusion alloys. 6063 aluminum occupies the number one spot and 6061 occupies spot number two. As alloys in the 6000 serie, they both have magnesium and silicon as their primary alloying elements. Dus, they have many similar properties. 6061 offers higher strength, echter. Als zodanig, it is often used for more structural applications. 6063, anderzijds, is used for applications such as railing or trim, ramen, and doors, due to its better appearance and corrosion resistance.

Leuk vinden 6061, 5052 aluminum has magnesium as a primary alloying element. In the case of 5052, it is the only primary alloying element. 6061 has silicon as well. One of the key benefits of this alloy is its high level of weldability compared to other alloys. For projects where weldability is key, it is worth considering. One downside to 5052, though, is that it is not heat treatable. It is good for a variety of welding applications and it works well in marine applications due to its high corrosion resistance.

Primarily used in aerospace applications, de 2024 alloy is known for high strength. Its main alloying element is copper, and although it is strong and has good fatigue resistance, it is less machinable and more difficult to weld than 6061. It also offers poor corrosion resistance and is often used in wing and fuselage structures which come under high tension.

A member of the 6000 serie, 6061 aluminum’s main alloying elements are magnesium and silicon, and it’s a great example of a jack of all trades. The alloy is somewhat universal, seeing some exposure in structural and building products as well as the aerospace and recreation industries.

Legering 6061 aluminum plate displays good tensile strength, which can be improved by temper treatment, and good corrosion resistance, lasbaarheid, and workability. Its workability makes it the right choice for many extrusion projects, as it is easy to form.

The alloy is widely available at a relatively low cost and is a great option to produce varied and precise components in different shapes. Although alloy 6061 doesn’t rank first in any aluminum properties tier list, it’s a great and reliable all-around aluminum alloy to work with.

-

-

-