Description

1085 aluminum sheet plate is a kind of industrial pure aluminum with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity.

The 1085 aluminum content must reach more than 99.85%, and also contain small amounts of copper, magnesium, zinc and other elements. The content of these elements has clear standard limits.

The Physical properties of 1085 aluminum sheet have low density, good electrical conductivity, high thermal conductivity, melting point of about 660 degrees Celsius, good ductility and formability. In the air, its surface can form a dense oxide film, which has good corrosion resistance.

Due to its good formability, surface treatment and corrosion resistance, 1085 aluminum plate is widely used in the production of daily necessities, lighting fixtures, reflective panels, decorations, chemical industry containers, heat sinks and other products.

Alloy: 1085

Temper: H18 H12 H14 H16 H18 H112 H22 H24 H26 O

Thickness: 0.2mm-6mm

Width: 900mm-1300mm

Application: bottle caps, industrial equipment, containers etc.

1085 aluminum sheet is a 1000-series aluminum alloy. It is considered commercially pure, just as 1050 aluminum coil, and is formulated for primary forming into wrought products.

1085 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-1085. Additionally, the EN chemical designation is Al99,85. And the UNS number is A91085.

Aluminium 1085 is featured by high conductivity, good corrosion resistance, high latent heat, high reflectivity, good welding performance, low strength etc.

Aluminum grade 1085 chemical composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | AL |

| 0.10 | 0.12 | 0.03 | 0.02 | 0.02 | – | 0.03 | 99.85 + |

1085-H112 Aluminum

1085-H112 aluminum is 1085 aluminum in the H112 temper. This temper is actually just a variation on F (as-fabricated) that allows for the possibility of very limited strain hardening or heat treatment, under certain conditions.

It has the second lowest strength and second highest ductility compared to the other variants of 1085 aluminum.

1085-H12 aluminum is 1085 aluminum in the H12 temper. To achieve this temper, the metal is strain hardened to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H18).

1085-H14 aluminum is 1085 aluminum in the H14 temper. To achieve this temper, the metal is strain hardened to a strength that is roughly halfway between annealed (O) and full-hard (H18).

1085-H16 aluminum is 1085 aluminum in the H16 temper. To achieve this temper, the metal is strain hardened to a strength that is roughly 3/4 of the way between annealed (O) and full-hard (H18).

1085-H18 aluminum is 1085 aluminum in the H18 temper. This is the strongest temper normally produced through the action of only strain hardening. It has the highest strength compared to the other variants of 1085 aluminum.

1085-H22 aluminum is 1085 aluminum in the H22 temper. To achieve this temper, the metal is strain hardened, and then partially annealed, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H28).

1085-H24 aluminum is 1085 aluminum in the H24 temper. To achieve this temper, the metal is strain hardened, and then partially annealed, to a strength that is roughly halfway between annealed (O) and full-hard (H28).

1085-H26 aluminum is 1085 aluminum in the H26 temper. To achieve this temper, the metal is strain hardened, and then partially annealed, to a strength that is roughly 3/4 of the way between annealed (O) and full-hard (H28).

1085-O aluminum is 1085 aluminum in the annealed condition. It has the lowest strength and highest ductility compared to the other variants of 1085 aluminum.

Advantages

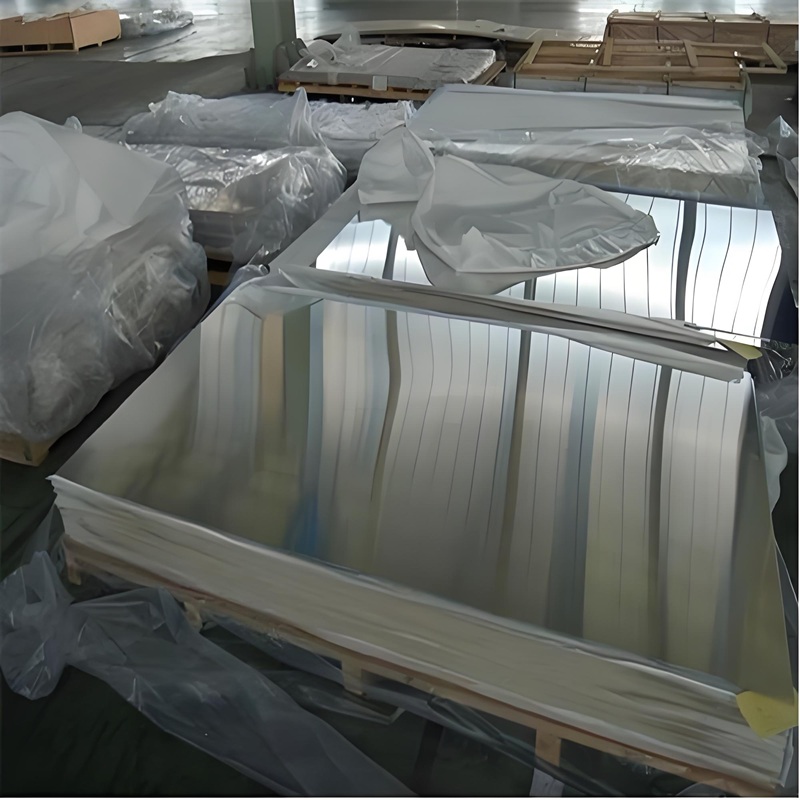

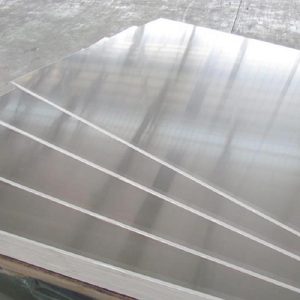

(1) Flat and smooth surface, no scratches, no foam on the surface

(2) Excellent optical performance

(3) Stable chemical stability

(4) Airworthy wooden box packaging and competitive price

What is the difference in application fields between 1085 aluminum plate and aluminum coil?

There are obvious differences in the application fields of 1085 aluminum sheet plates and aluminum coils, which are mainly determined by their shapes, processing characteristics and performance characteristics.

1. Application fields of 1085 aluminum sheet

1085 aluminum plate is widely used in many fields due to its good formability, surface treatment and corrosion resistance.

Manufacturing of daily necessities: such as kitchen utensils, tableware, etc., using the light weight, corrosion resistance and easy processing characteristics of 1085 aluminum plates, daily necessities that are both beautiful and practical can be produced.

Manufacturing of lighting fixtures: such as reflectors, lamp casings, etc. The high reflectivity and good formability of 1085 aluminum plates make it an ideal material for lighting fixtures.

Decoration manufacturing: such as artwork, decorative panels, etc., 1085 aluminum sheets can be subjected to a variety of surface treatment processes, such as polishing, spraying, etc., to produce decorations with unique aesthetics.

Chemical industry containers: Taking advantage of its corrosion resistance, 1085 aluminum plates can be used to make containers for storing chemical substances.

Electronic equipment heat sink: In electronic equipment, 1085 aluminum plate is often used as a heat sink, using its good thermal conductivity to dissipate heat.

2. Application areas of 1085 aluminum coils

Compared with 1085 aluminum plates, the application areas of 1085 aluminum coils are mainly concentrated in situations where continuous processing and large area coverage are required.

Here usage Specifically:

Building materials: 1085 aluminum coils are often used to make curtain walls, ceilings, window frames and other building materials. Its lightweight, corrosion-resistant and easy-to-process properties make it one of the preferred materials in modern construction.

At the same time, aluminum coils can also undergo a variety of surface treatment processes, such as spraying, anodizing, etc., to increase their aesthetics and weather resistance.

Electronic components: In the manufacturing of electronic components, 1085 aluminum coils are often used as radiators, battery casings and other components.

Using its good thermal conductivity and electromagnetic shielding properties, electronic components can be effectively protected from interference and damage by the external environment.

Environmentally friendly packaging: With the continuous improvement of environmental protection requirements, 1085 aluminum coils have gradually replaced traditional packaging materials and become an ideal choice for packaging food, medicine, etc. Its light weight, easy processing and corrosion resistance make it one of the preferred materials in the packaging industry.

In addition, 1085 aluminum coils are also widely used in billboards, license plates, building exterior decoration and other fields. Its good processing properties and beautiful appearance make it one of the preferred materials in these fields.

–

–

–