Description

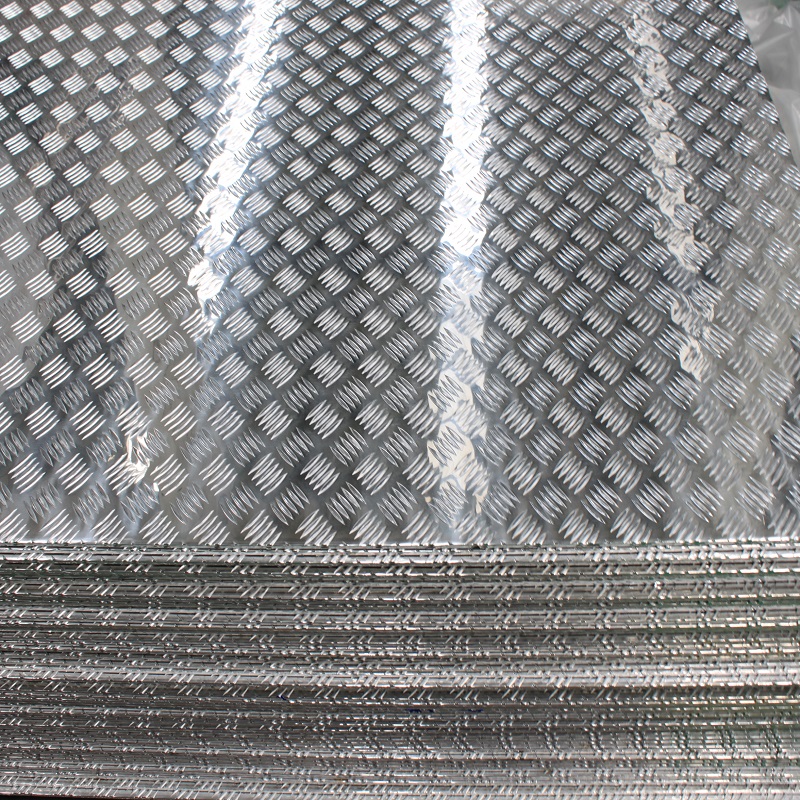

3003 h22 aluminum diamond plate always shows features like lightweight, highly polished surface, concise, durability, as well as better formability, weldability, skid & corrosion resistance, no low-temperature brittleness, etc.

We mostly supply variety of aluminum tread plate in both 3003 and 6061 alloys. Commonly referred to as “Diamond aluminum tread plate” due to its raised diamond-shaped pattern, And tread aluminum plate exhibits strength, durability, ease of welding, corrosion resistance and skid resistance. Aluminum Tread plate is available in 3003 with the typical H22/24 temper where welding is readily accomplished. For the highest strength applications, Tread plate

aluminum Diamond plate

is in 6061, frequently heat treated and aged to T6 temper.

Aluminum Tread Plate Applications

- Loading Ramps

- Stair Tread

- Flooring

- Dock Plate

- Dock Board

- Decorative purposes

- Fire Trucks

- Ambulances

- Recreational Vehicles

Aluminum diamond plate pattern helps minimize the risk of slipping making it an excellent use in industrial settings like stairs, ramps and walkways.

| ALLOY/TEMP | SIZE(FT) | SIZE(IN) | SIZE(MM) |

| 3003 H22/24 | .0525*4*8 | .063×48×96 | 1.6×1219×2438 |

| 3003 H22/24 | .525*4*10 | .063×48×120 | 1.6×1219×3048 |

| 3003 H22/24 | .02*4*10 | .250×48×120 | 6.35×1219×3048 |

| 3003 H22/24 | .01*4*8 | .125×48×96 | 3.175×1219×2438 |

| 3003 H22/24 | .02*4*16 | .250×48×192 | 6.35×1219×4876 |

Aluminum Brite tread plate aslo was called Diamond aluminum plate,and mostly popular used alloy is 3003 ,4017 and 5052.

Aluminum Tread Plate 3003 is a textured plate of 3003 aluminum alloy.

3003 Aluminum alloy is the most widely used of all aluminum alloys. It is essentially commercially pure aluminum with the addition of Manganese which increases strength some 20% over 1100. With excellent corrosion resistance and workability it can be deep drawn or spun, welded or brazed.

3003, 4017 and 5052 aluminum tread plate is available in full size and custom cut lengths in our factory.

The 3003 h22 aluminum tread plate is made of rust-proof 3000 series AL-MN aluminum alloy and other billets through equipment rolling.

3003 H22 aluminum has better properties, with highly cost-effective and practical. As for the h22 of 3003 h22 aluminum, refers to the H22 tempering state and the 2 hardening degree obtained, after processing hardening and incomplete annealing of 3003 aluminum. Meanwhile, the strength of 3003 h22 is between annealed (O) and full-hard (H28).

3003 h22 aluminum properties also show excellent formability, ductility, processability, surface handling, weldability, corrosion resistance, etc. So aluminium 3003 h22 sheet alloy is widely used for architectural decoration, marine, vehicle transportation, manufacturing, and other fields.

3003 alloy aluminum have equivalent name like A3003, 3003a, aa3003, 3003aa, al3003, al3003a, a 3003, aa 3003, jis a3003p, al3003 class, aw3003, en3003 grade etc.

Thickness:0.2-350mm

Width:30-2600mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5-10ton per size

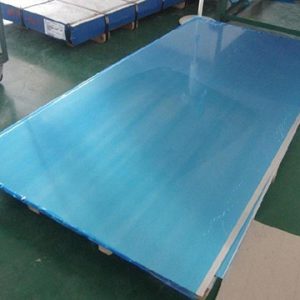

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209, EN573

4017 aluminum tread plate as new alloy in many parts is equivalent to a 3003 aluminum tread plates. for example, the corrosion resistance of the 4017 tread plate is the same as 3003 Grade, and with a bright finish tread surface also similar to 3003 aluminum tread plate,etc., although the 4017 is registered in EN 573-3 as 4017.

Aluminium alloy 5052 in H32 temper has very good corrosion resistance to seawater and marine and industrial atmosphere. It also has very good weldability and good cold formability. But it higher cost than 3003 and 4017.

–

–

–