Description

Aluminum sheet is a popular product for aerospace applications, and we produce and stock a dedicated range of aerospace-grade material which is available for immediate supply. We carry aviation aluminum plate or aerospace aluminum sheet or aircraft aluminium plate in alloy 2014 2024T3 2124 2219 6013 6061T6 7050 7075 7475.

2024 aluminum coil are considered the “aircraft” alloy because of its strength. It is readily formed in the annealed condition and may be subsequently heat treated. 2024 aluminum sheets possess good machinability and can be machined to a high finish

2024 aluminum plate is heat-treatable aluminum alloy with copper as the primary alloying element. It is malleable when in the fully soft, annealed temper and can be heat-treated to high strength levels after forming. Due to its high strength to weight ratio, it is widely used in aerospace application.

6061 aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2XXX series or 7XXX series, its magnesium and silicon alloys have many characteristics, excellent processing performance and excellent welding characteristics. And electroplating, good corrosion resistance, high toughness and no deformation after processing, dense material without defects and easy to polish, easy to color film, excellent oxidation effect and other excellent characteristics.

7075 aluminum alloy (AA7075) is an aluminum alloy with zinc as the primary alloying element. It has excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It has moderated formability when in the fully soft, annealed temper and can be heat-treated to strength levels that are comparable to many steel alloys. In fact, grade 7075 aluminum is stronger than many types of mild steel.

7075-T6 aluminum has nearly double the strength-to-weight of grade 2 titanium

the 7075 Al alloy is most preferred by the aircraft industry. The composition of this specific Al alloy is 5.1–6.1% zinc, 2.1–2.9% magnesium, 1.2–2.0% copper and less than 0.5% of silicon, iron, manganese, titanium, chromium and other trace metals

One of the key reasons to consider 7075 aluminum is for its high strength. Alloyed with zinc, it is one of the strongest alloys available and stronger than 6061. But it offers a lower level of corrosion resistance than 6061 and is also more difficult to weld. 7075 is used in marine, automotive, and aerospace applications where strength is a very high priority. It is also used in a firearms manufacturing and is even used in hang glider frames

Aluminum Sheet / Plate 7075-T6/T651 is normally used for aerospace, military, and automotive applications. 7075 aluminum is the strongest aluminum, with the strength of many steels, while retaining aluminum’s lightweight qualities and corrosion resistance.

Size of aluminum sheet

Thickness:0.2-6.0mm

Width:100-2400mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5ton per size

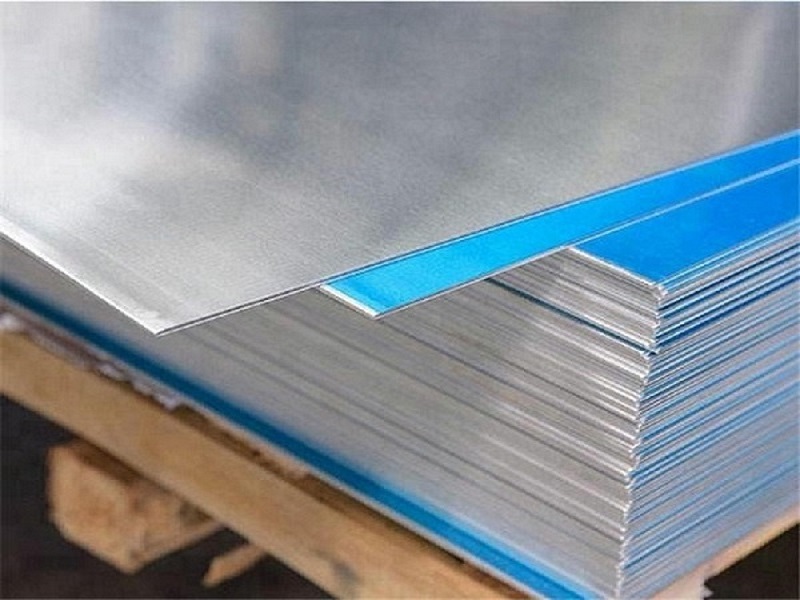

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209

Delivery time: about 30days after receiving the deposit.

–

–

–