Description

Beverage cans Aluminum 3004 is a medium strength aluminum alloy with manganese and magnesium as its primary alloying elements. It has higher strength than 3003 alloy but lower ductility. 3004 aluminum is a 3000-series aluminum alloy: the main alloying addition is manganese, and it is formulated for primary forming into wrought products. 3004 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-3004. AlMn1Mg1 is the EN chemical designation

Aluminium cans are also fully recyclable, so they have a low environmental impact. Aluminium is light, durable and 100% recyclable, making it the perfect material for beverage cans. Aluminium cans are used for a variety of beverages, including soda, beer, energy drinks and more.

The bodies of beverage cans are made of aluminum alloy (Al) 3004, while the ends are made of Al 5182, making it the largest volume alloy combination in the industry.

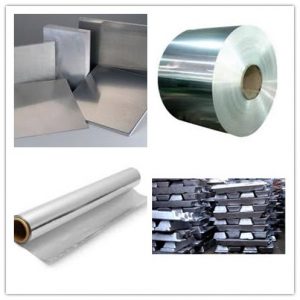

The Al 3004 aluminum plate alloy is a variant of the 3003 aluminum plate. It has good formability, weldability and corrosion resistance. It is mostly used for processing and requires good formability and high corrosion resistance. Good solderability products. Because aluminum itself has good oxidation resistance, it is used in the can body to prevent the oxidation and corrosion of carbonated beverages on the can body.

aluminum is easier to handle and less expensive to ship. From custom aluminum bottles and aerosol cans to other types of Al packaging, Aluminum also offers an unmatched combination of high strength, lighter weight and corrosion resistance.

UNS A93004 Aluminum Alloy plate and strips are widely used in decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and other industries. Aluminum materials are used in aircraft skins, fuselage frames, etc.

Aluminum 3004 sheet has many uses due to good strength, excellent corrosion resistance, good formability, good workability and drawing characteristics. This includes beverage cans, chemical equipment, hardware, storage tanks, and lamp bases

Aluminum 3004 is very similar to 3003 aluminum in its composition and end-uses. However, 3004 shows more strength due to a 1% addition of magnesium. As with all 3xxx aluminum alloy series, 3004 aluminum is non-heat treatable. Just a slight addition of magnesium gives 3004 strength approaching that of 5052 aluminum

Composition of 3004 aluminum alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others

Each |

Others

Total |

Al |

| 3004 | 0.30 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | – | 0.25 | 0.25 | 0.05 | 0.15 | Remainder |

Mechanical properties of 3003 aluminium alloy plate

| Alloy | 3004 |

| Tensile strength | 215 MPa |

| Yield strength | 170 MPa |

| Shear strength | 115 MPa |

| Fatigue strength | 105 MPa |

| Elastic modulus | 70-80 GPa |

| Poisson’s ratio | 0.33 |

| Elongation | 10% |

| Hardness | 52 |

Edible aluminum is also called food-grade aluminum, which is 3004 aluminum alloy. It is a metal packaging material, mainly used to make cans, lids, bottles, barrels, packaging foil, etc., in beverages, food, cosmetics, pharmaceuticals, industries Products and other packaging industries are widely used.

Aluminium Coil Supplier RAYIWELL MFG / RUIYI can offer aluminum sheet grade below

1000 series:1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series:2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series:3003,3004,3102,3104,3105,3005, etc.

4000 series:4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series:6061,6063,6262,6101, etc

7000 series:7072,7075,7003 etc

–

–

–