Description

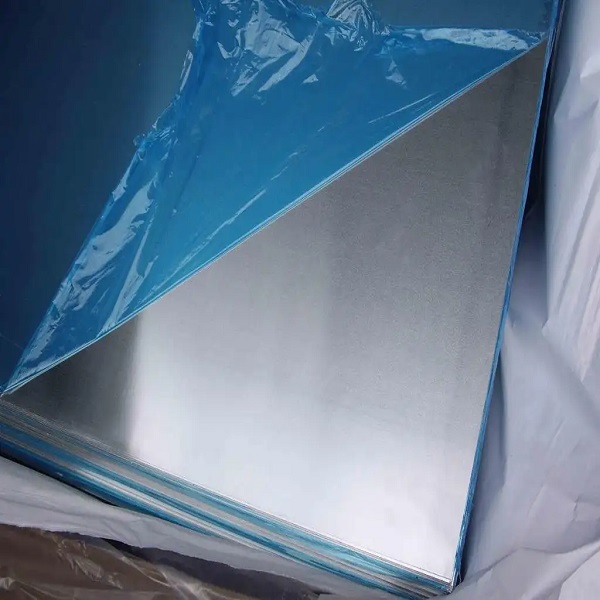

As top China 1050 H14 aluminum sheets supplier in China, RAYIWELL Mfg can supply aluminium sheet, aluminium plate, and aluminum coils, coated aluminum plate or color aluminum coils with different alloy grade.

1050 aluminum strip belongs to a product in the pure aluminum series, which is similar to the chemical composition and mechanical properties of 1060 series products, and is basically replaced by 1060 aluminum strip in application.

Aluminum 1050 sheet, also known as 1050A H14 plate, is a common type of aluminum sheet used in general metal fabrication. It is especially useful in medium-strength applications. Its properties include high corrosion resistance, ductility, and a reflective finish.

1050 contains 99.5% aluminum. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in conventional industries. Industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, and can accept contact welding and gas welding.

Industrial pure aluminum cannot be strengthened by heat treatment, but the strength can be improved by cold deformation. The only form of heat treatment is annealing. The recrystallization starting temperature is related to the impurity content and deformation degree, generally around 200°C

1050 aluminum strips are often used in daily necessities, lighting appliances, reflectors, decorations, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some occasions that require high corrosion resistance and formability, but not high requirements for strength, chemical equipment is a typical application.

What is the difference between aluminum plate AL1050 and AL1060?

1. Different uses: the national standard 1050 aluminum plate contains 99.5% aluminum, the production process is relatively simple, strong corrosion resistance, high plasticity, 1060 aluminum plate contains 99.6% aluminum, 1060 aluminum plate has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity Good features, 1060 aluminum plate has good elongation and tensile strength, which can fully meet the conventional processing requirements (stamping, stretching) and high formability.

2. The content is different: the national standard 1050 aluminum plate contains 99.5% aluminum, and the 1060 aluminum plate contains 99.6% aluminum. Because the materials of the two aluminum plates are very close, in actual use, 1050 aluminum plate is often replaced by 1060 aluminum plate.

Aluminum plate refers to a rectangular plate processed by rolling aluminum ingots, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium-thick aluminum plate, and patterned aluminum plate.

Aluminium Coil Aluminum Plate Sheet Supplier RAYIWELL MFG / RUIYI can offer aluminum sheet grade below

1000 series:1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series:2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series:3003,3004,3102,3104,3105,3005, etc.

4000 series:4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series:6061,6063,6262,6101, etc

7000 series:7072,7075,7003 etc

8000 series: 8011, etc.

Temper of aluminum sheet: O, H, W, F, T

H:H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

T: T0-T651

Size of aluminum sheet

Thickness:0.2-6.0mm

Width:100-2400mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5ton per size

1050 aluminum sheet are often used in daily necessities, lighting appliances, reflectors, decorations, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some occasions that require high corrosion resistance and formability, but not high requirements for strength, chemical equipment is a typical application

1050 aluminum sheets are widely used in industrial applications, particularly in those that require excellent corrosion resistance and ductility. It is also used in pyrotechnic powder, pole materials, and signs, and is known for its high reflectivity. 1050 aluminum sheet has higher thermal conductivity than other types of Aluminium.

1050 Aluminum Sheet is a type of Aluminium-based alloy that belongs to the 1000 series aluminum alloy family. This metal is usually formed by rolling or extrusion, and is most commonly used in electrical and chemical industries. It has excellent corrosion resistance and high tensile strength. It is also highly reflective and can be formed into a variety of shapes. Aluminium Alloy 1050 Sheets are manufactured to meet the highest quality standards.

–

–

–