Description

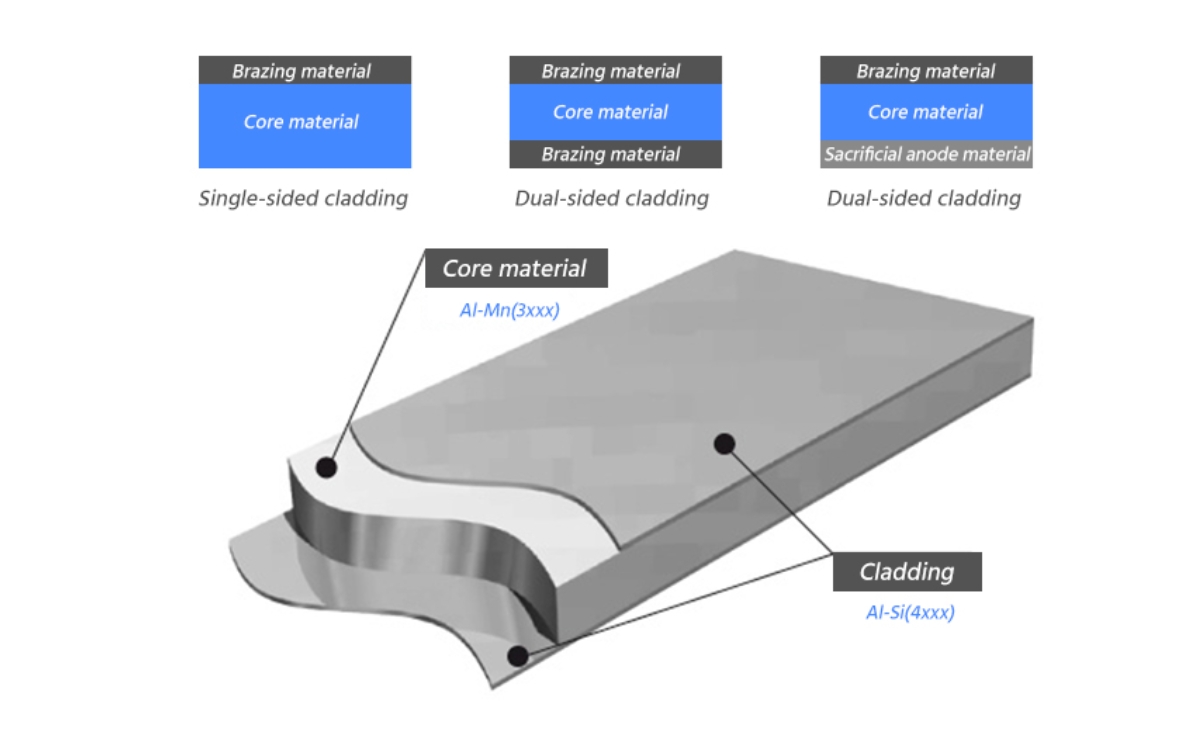

Clad aluminum sheet typically refers to a type of material where two layers of aluminum are bonded together with a thin layer of another metal in between. This process is often used to combine the desirable properties of aluminum, such as its lightweight nature and corrosion resistance, with those of other metals, such as strength or conductivity

Common applications for clad aluminum sheet include:

1. Cookware: Clad aluminum is often used in the production of high-quality cookware due to its excellent heat conductivity and even heat distribution.

2. Architecture and Construction: Clad aluminum panels are used in architectural applications for their durability, lightweight nature, and aesthetic appeal.

3. Transportation: In the aerospace and automotive industries, clad aluminum sheets are used in the manufacturing of aircraft structures, automotive body panels, and other components where a combination of strength and lightness is required.

| Product Name | Clad aluminum sheet |

| Specification Ranges | <0.050.20) x (12-1300) |

| Alloy | 4343/3003/4343, 4343/3003+1.0%Zn/4343, 4343/3OO3+1.5%Zn/4343, 4343/3Z19/4343, 4045/3003/4045, |

| Temper | 0. H14. H24. H18 |

| Aplication Area | Used for outer-fln or Inner-fln of Inter Cooler, etc |

Clad aluminum sheet vs. bare aluminum sheet: Choosing the right material for your project

When it comes to aluminum, there are two main options to consider: clad aluminum sheet and bare aluminum sheet.

Both have their own unique characteristics and are used in various industries and applications. Understanding the differences and advantages of each material can help you make an informed decision when choosing the right material for your project.

Clad aluminum is a composite material that consists of layers of aluminum alloys bonded together through a process called roll bonding.

This creates a material that combines the advantages of different aluminum alloys, such as strength, corrosion resistance, and formability. The most common type of clad aluminum is aluminum clad steel, where a layer of aluminum is bonded to a steel core.

Advantages of clad aluminum sheet:

1. Corrosion resistance: Clad aluminum offers superior corrosion resistance compared to bare aluminum, making it ideal for applications in marine environments or harsh outdoor conditions.

2. Strength: The combination of different aluminum alloys in clad aluminum results in a material with higher strength and durability.

3. Formability: Clad aluminum can be easily shaped and formed into complex designs, making it suitable for applications that require intricate shapes.

4. Cost-effective: While clad aluminum may be slightly more expensive than bare aluminum, its superior properties can lead to cost savings in the long run due to reduced maintenance and replacement costs.

Bare aluminum, on the other hand, refers to aluminum that is not coated or bonded with any other material. It is a pure form of aluminum that is widely used for various applications due to its lightweight, ductility, and conductivity.

Advantages of bare aluminum sheet:

1. Lightweight: Bare aluminum is one of the lightest metals, making it ideal for applications where weight is a critical factor, such as aerospace and automotive industries.

2. Conductivity: Aluminum is an excellent conductor of electricity and heat, making it suitable for electrical wiring, heat exchangers, and other applications that require thermal conductivity.

3. Recyclability: Aluminum is a highly recyclable material, and bare aluminum can be easily recycled and reused to reduce environmental impact.

4. Cost-effective: Bare aluminum is generally more cost-effective than clad aluminum, making it a popular choice for budget-conscious projects.

Choosing the right material for your project

When deciding between clad aluminum sheet and bare aluminum sheet for your project, consider the specific requirements, such as strength, corrosion resistance, formability, and budget constraints. If corrosion resistance and strength are critical factors, clad aluminum may be the better option.

However, if lightweight and conductivity are more important, bare aluminum may be the ideal choice.

Ultimately, the decision between clad aluminum sheet and bare aluminum sheet will depend on the specific needs of your project and the desired properties of the material.

By understanding the advantages and characteristics of each material, you can make an informed decision that aligns with your project goals and requirements.

–

–

–