Description

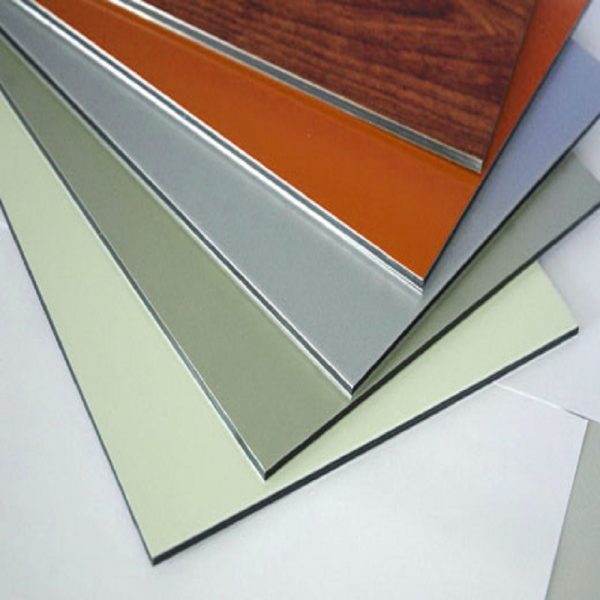

Aluminium panel sheet is a decorative material made of aluminium alloy plate after chrome treatment and then painted on the surface of raw aluminum sheets.

Aluminium panel sheet is a decorative material made of aluminium alloy plate after chrome treatment and then painted on the surface of raw aluminum sheets.

The raw aluminum sheets for aluminium panel sheet are mainly aluminum plates made from high quality 1000 series aluminum or 3000 series aluminum. Among them, 1100 aluminum sheet and 3003 aluminum plates are the most popular types in the market.

The next is the coating types on the surface of aluminum clad. Common aluminum wall covering coatings include PVDF paint, PET paint and Powder coating. Generally, PVDF paint is the best coating for exterior aluminum panels. Because PVDF aluminum sheet wall covering has better weatherability, it can cope with various weather conditions, and it will not be easily damaged. The price of PE aluminium wall covering is cheaper than PVDF, but its durability is not as good as PVDF. Therefore, for interior aluminum wall panels, PE coating is a better choice.

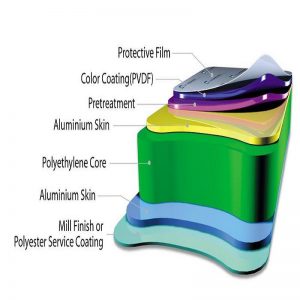

The PVDF aluminum composite panel consists of two sheets of corrosion resistant aluminum permanently bonded to polyethylene core material. The front aluminum coats PVDF (Fluor resin) paint. Because of its excellent weather proof and other features, this aluminium composite material becomes a very popular cladding material in the world.

Specifications

Panel thickness 3mm,4mm.5mm,6mm

Panel width 1000mm,1220mm,1250mm,1350mm,1500mm,1570mm

Panel length 2440mm-5800mm,or per customer’s request

Alu skin thickness 0.25mm,0.30mm,0.35mm,0.40mm,0.45mm,0.50mm

Standard size 1220(W) ×2440(L)mm

paint polyester coating

core Normal PE core

Fluoropolymers have been used in a multitude of high performance coating applications for over thirty five years. Poly(vinylidene fluoride) (PVDF) has been used especially in architectural applications, where both excellent appearance and substrate protection must be maintained over a very long period of time.

PVDF coatings can be applied by conventional coil or spray coating techniques, and baked at temperatures of 230-250 ºC.

–

–

–