Description

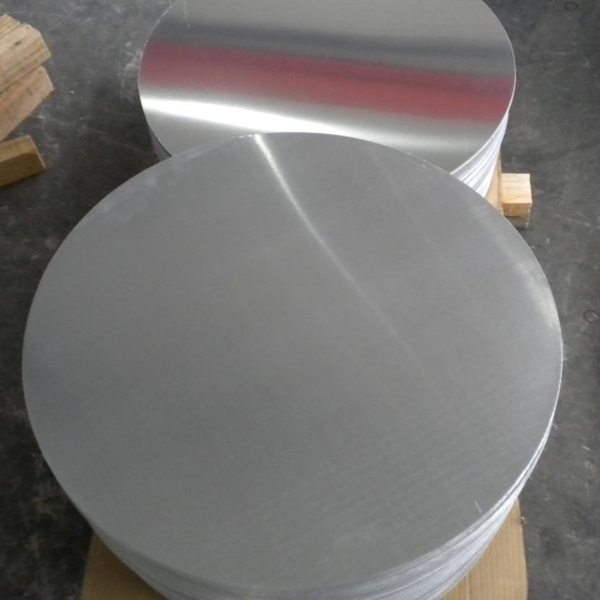

1100 aluminum circle refers to an aluminum product with a purity of 99.0% or higher, specifically designated as aluminum alloy 1100. This is a soft and ductile aluminum grade, also known as “aluminum annealed” or “aluminum cold-rolled.” It is commonly used for various applications due to its excellent corrosion resistance, formability, and workability.

1100 aluminum disc is a round material made of aluminum and aluminum alloys. Its main chemical components include aluminum, silicon, copper, magnesium, zinc and other elements.

Among them, the aluminum content should not be less than 99.00%, and the silicon content should not be higher than 0.40%.

In the context of manufacturing, an 1100 aluminum circle is a sheet of aluminum that has been rolled into a circular shape, often with a thickness ranging from very thin to several millimeters, depending on the specific requirements.

It is used in industries like automotive, construction, packaging, cookware, and signage, where a smooth surface and good mechanical properties are desired.

Aluminum Circles Product Specification:

- Alloy: 1050, 1060, 1070, 1100, 3002, 3003, 3004, 5052A, 5052, 5754, 6061

- Hardness: O, H12, H14, H16, H18

- Thickness: 0.012″ – 0.15″ (0.3mm – 4mm)

- Diameter: 3.94″ – 38.5″ (80mm -2000mm)

- Surface: Polished, Bright, Anodized

- Usage: Suitable for making pots, pans, pizza trays, pie pans, cake pans, covers, kettles, basins, fryers, light reflectors

- Stamping Materials Include: steel, galvanized steel, aluminum, aluminum alloy and other metals

1100 aluminum circle is a type of aluminum alloy that contains 99% aluminum and 1% other elements such as iron, silicon, copper, and zinc.

It is a soft and ductile material that is commonly used in various applications such as cookware, lighting reflectors, traffic signs, and chemical processing equipment.

The 1100 aluminum circle has excellent corrosion resistance, high thermal conductivity, and good electrical conductivity. It is also easy to form, weld, and machine, making it a popular choice for many industries.

Some common uses of 1100 aluminum circles include:

1. Cookware: As a base material for pots, pans, and other kitchen utensils due to its non-reactive nature and heat conductivity.

2. Architectural applications: For trim, fascia, and decorative elements in buildings, as it can be easily shaped and formed.

3. Electrical components: In electrical enclosures, switchboards, and wiring because of its electrical conductivity and lightweight.

4. Packaging: For food cans, beverage cans, and other packaging materials due to its recyclability and corrosion resistance.

5. Signs and advertising: As a substrate for printed graphics due to its smooth surface finish.

When ordering an 1100 aluminum circle, the size (diameter) and thickness will typically be specified, along with any additional surface treatments or finishes required, such as polishing, anodizing, or coating.

What are the specific applications of 1100 aluminum discs in the construction field?

The application of 1100 aluminum discs in the construction field is specifically reflected in the following aspects:

Building exterior siding, roof panels and ceilings:

1100 aluminum discs are very suitable for making building exterior wall panels, roof panels and ceilings due to their high corrosion resistance and good plasticity.

Its surface is smooth and flat, which can provide a beautiful appearance. At the same time, it has good fire resistance and can effectively prevent the spread of fire.

Decorative and structural materials:

1100 aluminum discs enjoy a good reputation in the field of architectural decoration. Various decorative materials and structural materials made of it can ensure good compatibility.

Whether it is used as a ceiling material, partition wall or other decorative board, it can show its unique beauty and practicality.

Lightweight and corrosion-resistant:

As a lightweight material, the 1100 aluminum discs made of aluminum can significantly reduce the weight of the overall structure and reduce construction costs while maintaining the stability and strength of the structure.

In addition, aluminum also has strong corrosion resistance and can resist erosion by various environmental factors and extend the service life of the building.

Processing performance:

1100 aluminum discs have excellent processing properties and are easy to cut, stamp, bend and weld, which allows them to be flexibly processed into various shapes and sizes according to the needs of architectural design to meet different building needs.

Environmental protection:

Aluminum is a recyclable material. Building materials made of 1100 aluminum discs can be recycled and reused after reaching their service life, which reduces the environmental burden and meets the requirements of sustainable development.

Aluminum plate is the thickness of more than 0.2mm to less than 500mm, more than 200mm width, length within 16m aluminum material is called aluminum sheet or aluminum sheet, below 0.2mm for aluminum,200mm width within the strip or bar.

| Aluminum plate technical parameters (commonly used models) | ||||

| Aluminum Plate model | Temper | Thickness(mm) | Width(mm) | Length(mm) |

| 1050 Aluminum plate | H111, H112, H14, H18, H19, H22, H24, H26, H28 | 0.2mm-500mm | 20mm-2630mm | customized |

| 1060 Aluminum plate | H111, H112, H14, H18, H19, H22, H24, H26, H28, etc. | 0.1-500mm | 20mm-2640mm | 500-10000mm |

| 1100 Aluminum plate | O, H14, H16, H24, H22, H112, H111, H26, H12, H28, etc. | 0.1-500mm | 0.1-500mm | 500-16000mm |

| 2024 Aluminum plate | T3, T4, T6, T72, T81, T351, T861, T3511, T8611, HO | 0.1mm-550mm | 700mm-2650mm | 500-11000mm |

| 3003 Aluminum plate | HO, H12, H14, H16, H18, H19, H22, h24, h26, H28, H112, etc. | 0.2mm-450mm | 50mm-2650mm | 500-12000mm |

| 5005 Aluminum plate | H12, H14, H16, H18, H22, h24, h26, H28, H36, H38, etc. | 0.2mm-600mm | 30mm-2650mm | 500-12000mm |

| 5052 Aluminum plate | H12, H14, H16, H18, H22, h24, h26, H28, H36, H38, etc. | 0.2mm-500mm | 60mm-2650mm | 500-10000mm |

| 5083 Aluminum plate | H111, H114, H116, H321, H22, H24, H26, H32, H16, H12, HO, etc. | 0.15mm-500mm | 30mm-2600mm | 500-9000mm |

| 6061 Aluminum plate | HO, F, T4, T6, T651 | 0.35mm-500mm | 500mm-2600mm | 600-11000mm |

| 6063 Aluminum plate | O,T6,T651,T4 | 0.15-600mm | 500mm-2800mm | 500-16000mm |

| 7050 Aluminum plate | HO, F, T112, T651, T6, T7451 | 1.0mm-600mm | 600mm-2500mm | 600-8000mm |

| 7075 Aluminum plate | HO, T651, T7451, T6, etc | 15.0mm-600mm | 500mm-2600mm | 600-8000mm |

–

–

–