Bobina de alumínio refere-se a uma placa fina laminada, a espessura é geralmente entre 0,2 ~ 4,5 mm, e a largura pode ser personalizada de acordo com as necessidades. Aluminum coils are usually made of pure aluminum or aluminum alloys and are lightweight, high-strength, and corrosion-resistant.

The manufacturing process of aluminum coils includes raw material pretreatment, smelting, fundição, rolling, desenho, cutting and other links. Entre eles, rolling is the most critical step in the alumínio coil manufacturing process. The rolling of aluminum coils is usually divided into two methods: hot rolling and cold rolling. Hot rolling is performed at high temperatures and is suitable for manufacturing thicker and larger aluminum coils; cold rolling is performed at room temperature and is suitable for manufacturing thinner and smaller aluminum coils.

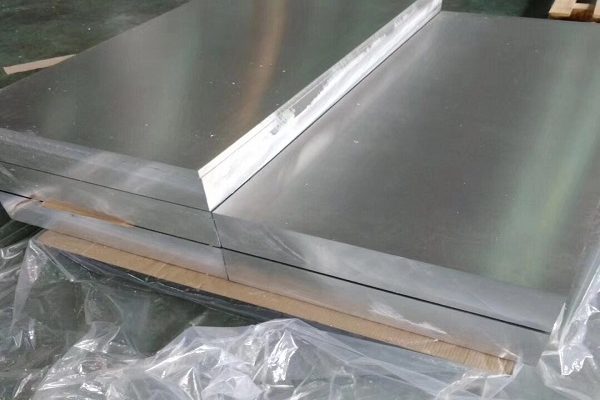

Characteristics of bobinas de alumínio

1. Lightweight and high strength: Aluminum alloy has a low density, so the aluminum coil has light weight and high strength.

2. Resistência à corrosão: The surface of the aluminum coil can be treated with oxidation and other treatments to obtain good corrosion resistance.

3. Good machinability: Aluminum coils can be processed by cutting, flexão, estampagem, soldagem, etc., and have good machinability.

4. Beautiful and easy to handle: the surface of the aluminum coil is flat and smooth, easy to carry out surface treatment, such as spraying, Revestimento, etc.

Application of aluminum coil

1. Construction field: Aluminum coils can be used to manufacture components such as building exterior walls, telhados, tetos, partições, etc., and have good decorative and corrosion resistance.

2. Aerospace field: Alumínio coil is an important material for manufacturing aircraft, and is widely used in the manufacture of aircraft, rockets, and satellites.

3. Electronic field: Bobinas de alumínio can be used as manufacturing materials for electronic product casings, radiators and other components, helping to improve the performance and reliability of electronic products.

4. Packaging field: Aluminum coils are suitable for manufacturing cans, embalagem de alimentos, pharmaceutical packaging and other fields, and have good sealing and anti-corrosion capabilities.

5. Transportation field: Aluminum coils can be used in the manufacturing of cars, trens, ships and other transportation vehicles, helping to reduce the weight of the vehicle body and improve the overall performance of the vehicle.