Aluminiu is a lightweight and versatile metal that has become increasingly popular in the automotive industry due to its numerous benefits. The use of aluminum in the automotive industry has revolutionized the design and production of vehicles, and its impact can be seen in the performance, fuel efficiency, and sustainability of modern cars. In this article, we will explore the influence of aluminum in the automotive industry and its impact on the overall economy.

The Importance of Aluminum in the Automotive Industry

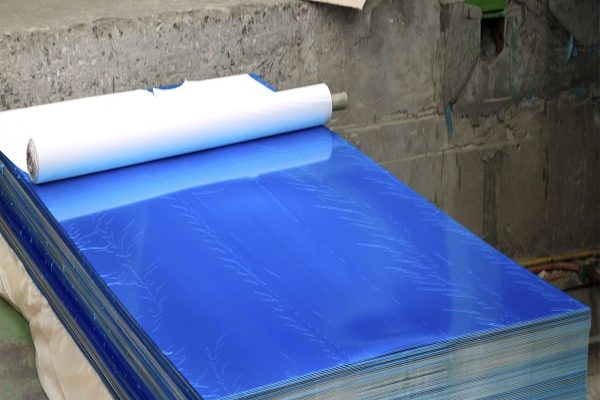

Aluminum is a lightweight and durable metal that is widely used in the automotive industry for its excellent mechanical properties. The use of aluminum in car construction has grown significantly in recent years due to the need for lightweight materials that can improve fuel efficiency and reduce emissions. Aluminum is an ideal material for lightweight, a process that involves reducing the weight of a vehicle without compromising its structural integrity. The influence of aluminum in the automotive industry can be seen in the increasing number of vehicles that use aluminum in their construction. Aluminum is used for various components, including body panels, engine blocks, rotile, and suspension parts. În plus, aluminum has become a preferred material for electric vehicles due to its lightweight and recyclable properties.

Effect on the Economy as a Whole

Aluminum’s use in the automotive sector has had a tremendous economic impact. Aluminum production and use contribute to many countries’ GDP, and the aluminum industry is critical to the automotive supply chain. The aluminum industry collaborates closely with automotive manufacturers to produce new aluminum alloys that fulfill the industry’s changing needs. Furthermore, the usage of aluminum in the automotive industry has had a favorable environmental impact. Aluminum-based lightweight vehicles use less gasoline, resulting in lower emissions and a cleaner environment.

Aluminium Industry Challenges in the Automotive Sector

Despite the various advantages of aluminum in the automotive sector, the industry confronts a number of obstacles. One of the major issues is the high cost of aluminum in comparison to other materials like steel. Furthermore, the use of aluminum in car building necessitates specialized production procedures and equipment, which can be costly for some automakers. Another issue that the aluminum industry has in the automobile sector is the difficulty in recycling aluminum. While aluminum is a recyclable material, the recycling process can be complex and expensive, making it difficult for some automakers to include aluminum recycling in their manufacturing processes.

Advancements in Aluminum Alloys:

The development of new aluminum alloys has played a crucial role in the increasing use of aluminum in the automotive industry. These alloys offer increased strength and durability while maintaining the lightweight properties of aluminum. The most commonly used aluminum alloys in the automotive industry include 5000, 6000, și 7000 series alloys.

The Role of Aluminum Suppliers:

The automotive industry relies heavily on furnizori de aluminiu for the provision of raw materials. Ca atare, aluminum suppliers play a critical role in the automotive supply chain and work closely with automobile manufacturers to develop new aluminum alloys that meet the changing needs of the industry.

Aluminum Recycling:

Aluminum is one of the most recyclable materials, and the automotive industry has been a significant contributor to aluminum recycling. Nearly 90% of scrapped vehicles are recycled, with aluminum being used for various applications, including the construction of new vehicles.

Impact of Aluminum Prices:

The price of aluminum has a significant impact on the automotive industry’s profitability, and fluctuations in aluminum prices can result in significant changes in automobile production costs. Ca atare, the industry is constantly monitoring aluminum prices and developing strategies to mitigate the impact of these fluctuations.

Use of Aluminum in Electric Vehicles:

Electric vehicles (EVs) require lightweight materials to improve their range and performance, and aluminum is an ideal material for EV construction. The use of aluminum in EVs is expected to increase significantly in the coming years as more automobile manufacturers shift towards electrification.

CONCLUSION:

The influence of aluminum in the automotive industry is significant and expected to grow in the coming years. Aluminum is an ideal material for lightweight, and its use has resulted in more fuel-efficient and environmentally friendly vehicles. The use of aluminum in the automotive industry has had a positive impact on the overall economy, and the aluminum industry plays a critical role in the automotive supply chain. in orice caz, the industry faces several challenges, including the high cost of aluminum and the difficulty in recycling aluminum. Nonetheless, the aluminum industry is working to overcome these challenges and develop new aluminum alloys that meet the changing needs of the automotive industry.