Описание

6061 Алюминиевая пластина Manufacturer Rayiwell MFG supply aluminum-silicon-magnesium alloy, strengthened by precipitation hardening. This alloy has medium strength, деформируемость, свариваемость, обрабатываемость и устойчивость к коррозии.

Алюминиевая пластина 6061 T6 temper has an ultimate tensile strength of at least 42,000 psi (290 МПа) and yield strength of at least 35,000 psi (241 МПа). In thicknesses of 0.250 дюйм (6.35 мм) or less, it has elongation of 8% или больше; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties.

сплав 6061 alumium plate has a relatively high strength, easily welded and is widely used not only for making bicycle frames, but also in construction, самолет, shipbuilding.

The main alloying elements in 6061 алюминиевая пластина are magnesium and silicon, с умеренной силой, хорошая коррозионная стойкость, weldability and oxidation effect. Widely used in various industrial structures requiring certain strength and high antibiotic corrosion resistance.

The main chemical components are: медь 0.15-0.4%, кремний 0.4-0.8%, утюг 0.7%, марганец 0.15%, магний 0.8-1.2%, цинк 0.25%, chromium 0.04-0.35%, титан 0.15%.

The difference between 6061 алюминиевая пластина T6 and T651 is that, under normal circumstances, the internal stress of T6 will be relatively large, and it will be deformed during processing. The most suitable state for processing should be T651, stretched on the basis of T6, and eliminate internal stress.

6061-T6 : cooling after solution heat treatment to achieve high strength, no cold working;

6061-T651 : Cooling after solution heat treatment to achieve high strength, and then cold stretching by stretching machine to eliminate residual internal stress after heat treatment, so as to ensure the precision of machined products without deformation after deep processing.

6061 T6 алюминий Plate is a commonly used aluminum alloy. Unless otherwise specified, it is generally in the 6061 T6, а также 6061 T651 is the best feature of the 6-series aluminum alloy, and it is a fighter in the 6000-series алюминий сплав. It has excellent processing performance, excellent welding characteristics and electroplating performance, хорошая коррозионная стойкость, high toughness, no deformation after processing, dense material without defects, easy polishing, easy coloring and film formation and excellent oxidation effect.

Since 6061-T651 is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process, although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, excellent processing performance and excellent welding Features and electroplating, хорошая коррозионная стойкость, high toughness and no deformation after processing, compact material without defects and east to polish, easy to color film, excellent oxidation effect and other excellent characteristics. The representative applications of 6061-T651 include aerospace fixtures, electrical fixtures, and communication fields, and are also widely used in automated mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carriers, и т.д.

The states of 6061 алюминиевые пластины are O temper, T4, T6, T651, и т.д. For different states, the application fields are different. 6061 aluminum plate has high strength, good anti-corrosion and anti-oxidation effects, and is widely used in automatic mechanical parts, precision machining, automobile chassis, cake molds, и т.п., and is deeply loved by users.

Both the 6061-T6 алюминиевая пластина and the 6061-T651 aluminum plate are commonly used. The difference between the T6 state of the 6061 aluminum plate and the T651 is:

The internal pressure of T6 is high, and the processing deformation is more suitable for processing. The state is T651, which eliminates internal stress on the basis of T6 extension. The main alloy elements of 6061 aluminum plate are magnesium and silicon, which have medium strength, высокая прочность, weldability and good oxidation effect.

Характер: T1,T2,T3, T4, T6, T651

Толщина:0.2-350мм

Ширина:30-2600мм

длина:200-11000мм

Материнская катушка: CC или DC

вес: Около 2 тонн на поддон для общего размера

MOQ: 5-10тонна на размер

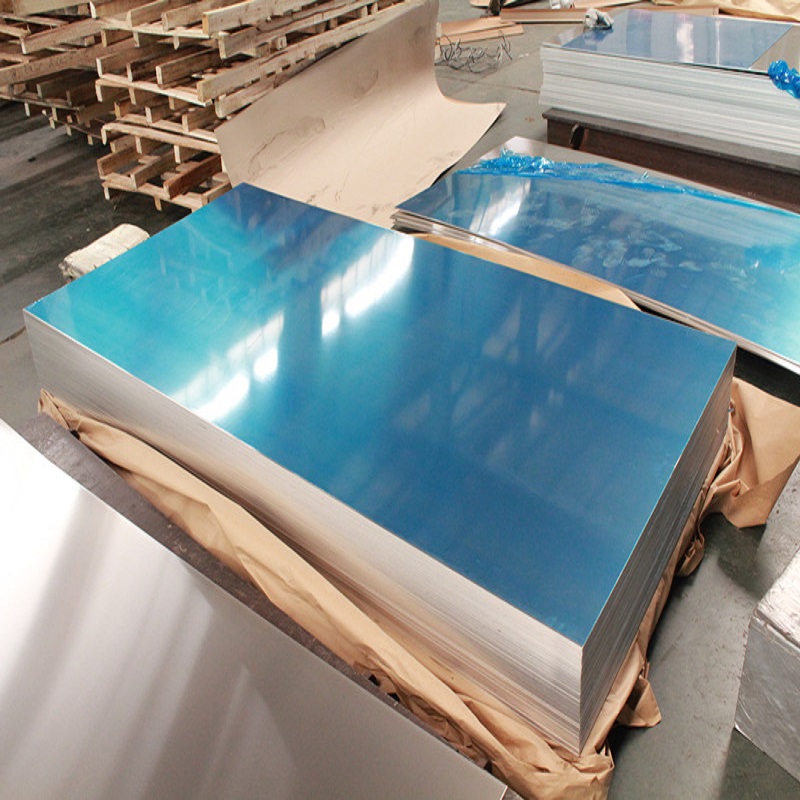

Защита: промежуточный слой бумаги, белая пленка, голубая пленка, черно-белая пленка, микро переплетенная пленка, согласно вашему требованию.

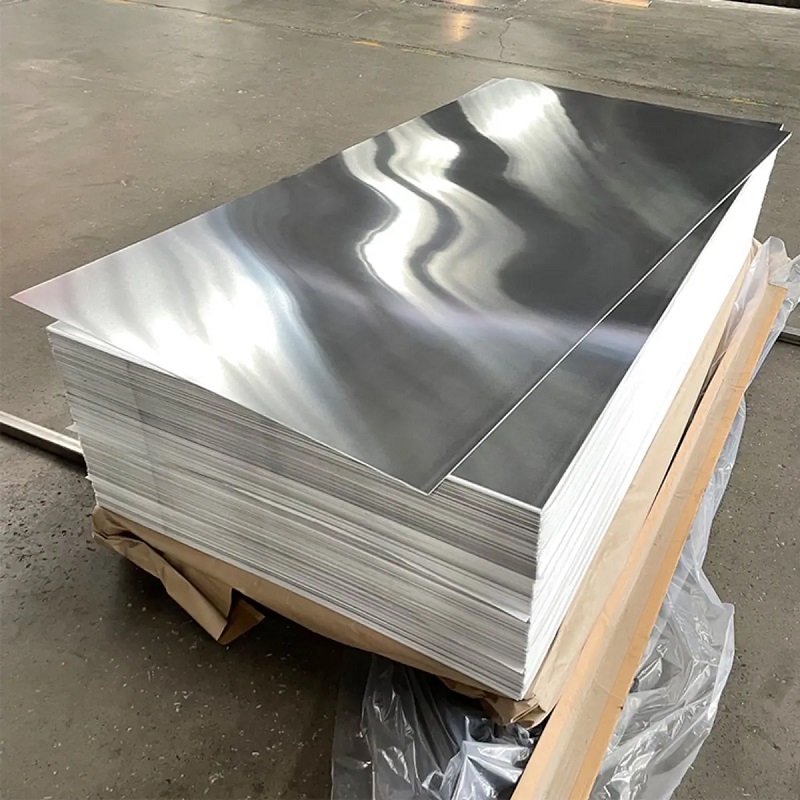

поверхность: чистый и гладкий, нет яркого пятнышка, коррозия, масло, прорезанный, и т.д.

Стандартный продукт: ГБТ3880, JIS4000, EN485, ASTM-B209, EN573, ASTMB221, AMS-QQ-A-200/8, ASMESB221

Срок поставки: Около 30 дней после получения депозита

Оплата: Т/Т, Аккредитив по предъявлении

Торговые условия: FOB, СИФ, CFR

Другие алюминиевая пластина alloy available

1000 серии:1050,1060,1070,1080,1100,1145,1200,1235, и т.д.

2000 серии:2014,2017,2018,2024,2025,2219, 2219,2618и т.д..

3000 серии:3003,3004,3102,3104,3105,3005, и т.д.

4000 серии:4032,4043, 4017, и т.д

5000 серии: 5005,5052,5454,5754,5083,5086,5182,5082, и т.д.

6000 серии:6061,6063,6262,6101, и т.д

7000 серии:7072,7075,7003 и т.д

8000 серии: 8011, и т.д.

Алюминиевый лист or aluminum plate is used in construction material and building material. Включая: панель крыши, потолок, в стене, перегородка, ставни, жалюзи, ворота,

балкон, стена, дорожная разметка, дорожные знаки, пластина для защиты дороги, пластина для защиты шоссе, несущая стена моста, строительные леса, корабельная табличка, и т.д.

Aluminum sheet is used in electric machine components. Включая: защитная пластина, защитная коробка, конденсаторная коробка, бак силового конденсатора, электролитический конденсатор, переменная батареи, объемный вал, каркас громкоговорителя, пластина переключателя, полупроводниковый радиатор, магнитный диск, моторная рама, ад уходит, электрическая плита, ребро охлаждения, радиатор, и т.д

-

-

-