popis

6061-T651 Aluminum coil supplier RAYIWELL MFG supply aluminum-silicon-magnesium alloy, strengthened by precipitation hardening. This alloy has medium strength, tvárnosť, zvariteľnosť, spracovateľnosť a odolnosť proti korózii.

hliníkový plech 6061 T6 temper has an ultimate tensile strength of at least 42,000 psi (290 MPa) and yield strength of at least 35,000 psi (241 MPa). In thicknesses of 0.250 palec (6.35 mm) or less, it has elongation of 8% alebo viac; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties.

zliatina 6061 alumium Coil has a relatively high strength, easily welded and is widely used not only for making bicycle frames, but also in construction, lietadlo, shipbuilding.

Hlavné legujúce prvky v 6061 hliníkový plech are magnesium and silicon, s miernou silou, dobrá odolnosť proti korózii, weldability and oxidation effect. Widely used in various industrial structures requiring certain strength and high antibiotic corrosion resistance.

The main chemical components of 6061 aluminum coil are: meď 0.15-0.4%, kremík 0.4-0.8%, železo 0.7%, mangán 0.15%, magnézium 0.8-1.2%, zinok 0.25%, chromium 0.04-0.35%, titán 0.15%.

The difference between 6061 hliníkový plech T6 and T651 is that, under normal circumstances, the internal stress of T6 will be relatively large, and it will be deformed during processing. The most suitable state for processing should be T651, stretched on the basis of T6, and eliminate internal stress.

6061-T6 : cooling after solution heat treatment to achieve high strength, no cold working;

6061-T651 : Cooling after solution heat treatment to achieve high strength, and then cold stretching by stretching machine to eliminate residual internal stress after heat treatment, so as to ensure the precision of machined products without deformation after deep processing.

6061 T6 hliník Plate is a commonly used aluminum alloy. Unless otherwise specified, it is generally in the 6061 T6, a 6061 T651 is the best feature of the 6-series aluminum alloy, and it is a fighter in the 6000-series hliník zliatina. It has excellent processing performance, excellent welding characteristics and electroplating performance, dobrá odolnosť proti korózii, high toughness, no deformation after processing, dense material without defects, easy polishing, easy coloring and film formation and excellent oxidation effect.

Since 6061-T651 is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process, although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, excellent processing performance and excellent welding Features and electroplating, dobrá odolnosť proti korózii, vysoká húževnatosť a žiadna deformácia po spracovaní, compact material without defects and east to polish, ľahko zafarbiteľný film, vynikajúci oxidačný účinok a ďalšie vynikajúce vlastnosti. The representative applications of 6061-T651 include aerospace fixtures, elektrické príslušenstvo, a komunikačné polia, a sú tiež široko používané v automatizovaných mechanických častiach, presné obrábanie, výroba foriem, elektronika a presné prístroje, SMT, Nosiče spájkovania dosiek PC, atď.

The different temper of 6061 hliníkové dosky sú O , T4, T6, T651, atď. For different temper, the application fields are different. 6061 aluminum plate has high strength, good anti-corrosion and anti-oxidation effects, and is widely used in automatic mechanical parts, presné obrábanie, automobile chassis, cake molds, atď., and is deeply loved by users.

Both the 6061-T6 hliníkový plech and the 6061-T651 aluminum plate are commonly used. The difference between the T6 state of the 6061 aluminum plate and the T651 is:

The internal pressure of T6 is high, and the processing deformation is more suitable for processing. The state is T651, which eliminates internal stress on the basis of T6 extension. The main alloy elements of 6061 aluminum plate are magnesium and silicon, ktoré majú strednú pevnosť, vysoká pevnosť, weldability and good oxidation effect.

zlosť: T1,T2,T3, T4, T6, T651

hrúbka:0.2-350mm

šírka:30-2600mm

dĺžka:200-11000mm

Materská cievka: CC alebo DC

závažia: Približne 2 mt na paletu pre všeobecnú veľkosť

MOQ: 5-10tona na veľkosť

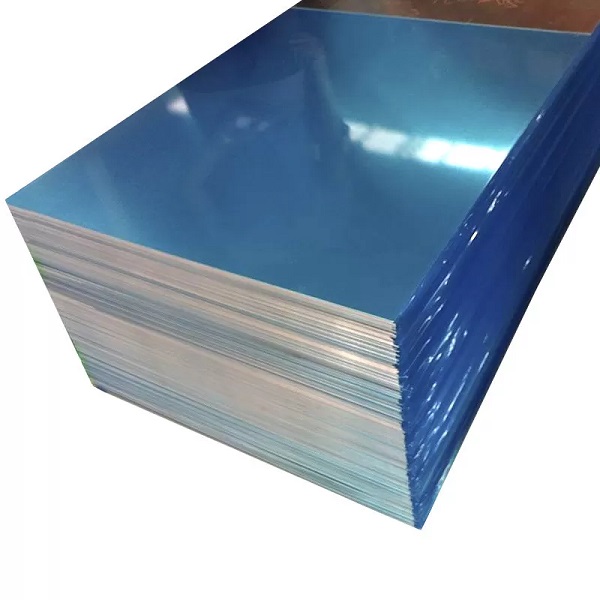

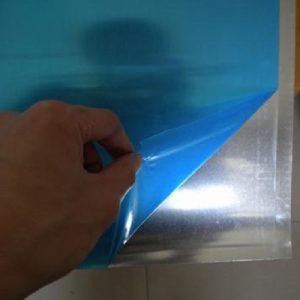

Ochrana: papierová medzivrstva, biely film, modrý film, čiernobiely film, mikro viazaný film, podľa Vašej požiadavky.

povrch: čisté a hladké, žiadna svetlá škvrna, korózia, oleja, Perforovaný hliníkový plech, atď.

Štandardný produkt: GBT3880, 4000 JIS, EN485, ASTM-B209, EN573, ASTMB221, AMS-QQ-A-200/8, ASMESB221

Dodacia lehota: asi 30 dní po prijatí zálohy

platba: T/T, L/C na dohľad

Obchodné podmienky: FOB, CIF, CFR

ostatné hliníkový plech alloy available

1000 séria:1050,1060,1070,1080,1100,1145,1200,1235, atď.

2000 séria:2014,2017,2018,2024,2025,2219, 2219,2618atď.

3000 séria:3003,3004,3102,3104,3105,3005, atď.

4000 séria:4032,4043, 4017, atď

5000 séria: 5005,5052,5454,5754,5083,5086,5182,5082, atď.

6000 séria:6061,6063,6262,6101, atď

7000 séria:7072,7075,7003 atď

8000 séria: 8011, atď.

hliníkový plech or aluminum plate is used in construction material and building material. Počítajúc do toho: strešný panel, strop, v stene, deliaca stena, okenice, okenná roleta, brána,

balkón, stena, cestné značenie, pouličné značky, cestná ochranná doska, diaľničný ochranný štítok, mostná nosná stena, lešenie, lodný tanier, atď.

Hliníková cievka sa používa v komponentoch elektrických strojov. Počítajúc do toho: ochranný plech, ochranný box, kondenzátorová skrinka, nádrž výkonového kondenzátora, elektrolytický kondenzátor, premenná batérie, objemový hriadeľ, reproduktorový rám, spínacia doska, polovodičový radiátor, magnetický disk, rám motora, peklo odchádza, elektrický varič, chladiaca plutva, chladič, atď

-

-

-