popis

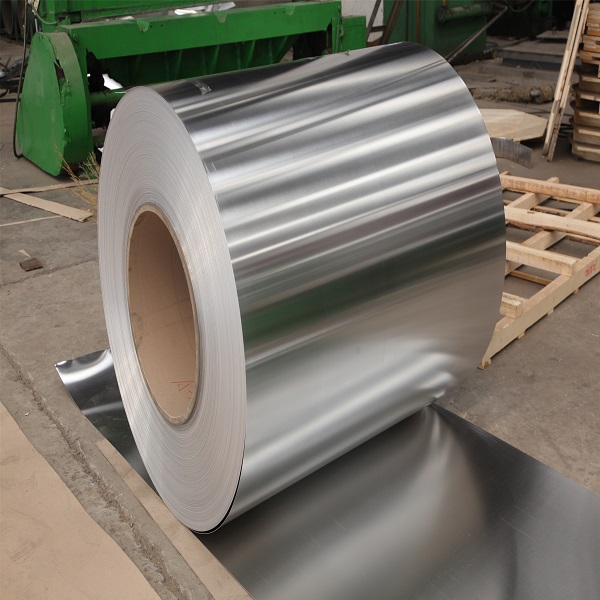

Hliníková cievka je kovový výrobok, ktorý je po valcovaní na odlievacom a valcovacom stroji podrobený letmým šmykom a spracovávaný ťahaním a ohýbaním uhlov.

Hliníková cievka sú široko používané v elektronike, balenie, výstavba, stroje, atď. RAYIWELL MFG / RuiYi Aluminium ako jeden z výrobcov hliníkových cievok v Číne, technológia výroby dobehla vyspelé krajiny.

According to the different metal elements contained in aluminium coil, it can be roughly divided into 9 Kategórie. , ktoré možno rozdeliť na 9 séria.

1000 séria

The representative 1000 series aluminium coil is also called pure aluminum plate. Among all the series, a 1000 series belongs to the series with the most aluminum content. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in conventional industries at present. Most of the circulating in the market are 1050 a 1060 séria.

The minimum aluminum content of the 1000 séria hliníková cievka is determined according to the last two Arabic numerals. Napríklad, the last two Arabic numerals of the 1050 série sú 50. Podľa medzinárodného princípu pomenovávania značiek, the aluminum content must reach 99.5% or more to qualify as a product. my country’s aluminum alloy technical standard (gB/T3880-2006) also clearly stipulates that the aluminum content of 1050 should reach 99.5%. In the same way, obsah hliníka 1060 series aluminum plates must reach more than 99.6%.

2000 Rad hliníkový plech

Representative 2A16 (LY16) 2A06 (LY6) 2000 series aluminum plate is characterized by high hardness, among which the content of copper is the highest, o 3-5%. The 2000 series aluminum plate belongs to aviation aluminum, which is not commonly used in conventional industries. There are fewer manufacturers of 2000 series aluminum sheets in my country.

3000 Rad hliníkový plech

Rep. 3003 3003 3A21-based. It can also be called anti-rust aluminum plate. The production process of 3000 series aluminum plate in China is relatively excellent. The 3000 series aluminum plate is mainly composed of manganese. The content is between 1.0-1.5. It is a series with better anti-rust function. Routinely used in humid environments such as air conditioners, chladničky, and undercars, the price is higher than the 1000 séria, and it is a more commonly used alloy series.

4000 séria hliníkový plech

The aluminum plate represented by 4A01 4000 series belongs to the series with higher silicon content. Usually the silicon content is between 4.5-6.0%. It belongs to building materials, mechanické časti, forging materials, welding materials; low melting point, good corrosion resistance Product description: Has the characteristics of heat resistance and wear resistance.

5000 séria

Represents the 5052.5005.5083.5A05 series. The 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy.

The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series. teda, it is often used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries. The processing technology is continuous casting and rolling, which belongs to the series of hot-rolled aluminum plates, so it can be used for oxidation deep processing.

6000 séria

It means that 6061 mainly contains magnesium and silicon, so the advantages of 4000 series a 5000 series are concentrated. 6061 is a cold-processed aluminum forged product, suitable for applications requiring high corrosion resistance and oxidation resistance. Good workability, excellent interface characteristics, easy coating, good processability. Can be used on low pressure weapons and aircraft connectors.

General characteristics of 6061: excellent interface characteristics, easy coating, vysoká pevnosť, dobrá spracovateľnosť, a silná odolnosť proti korózii.

Typické použitia 6061 hliník: aircraft parts, camera parts, couplers, marine accessories and hardware, electronic accessories and joints, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts .

7000 séria

On behalf of 7075 mainly contains zinc. It also belongs to the aviation series. It is an aluminum-magnesium-zinc-copper alloy. It is a heat-treatable alloy. It belongs to superhard aluminum alloy and has good wear resistance.

The thick 7075 aluminum plate is all ultrasonically detected, which can ensure no blisters and impurities.

The high thermal conductivity of the 7075 aluminum plate can shorten the forming time and improve work efficiency.

The main feature is that the hardness is high. 7075 is a high-hardness, high-strength aluminum alloy, which is often used in the manufacture of aircraft structures and futures. It requires high-stress structural parts with high strength and strong corrosion resistance, and mold manufacturing.

8000 séria

The more commonly used is 8011 which belongs to other series. In my memory, the aluminum plate is mainly used as a bottle cap, and it is also used in radiators, most of which are aluminum foil. Not very commonly used.

9000 séria

It belongs to the spare series, and the technology is so advanced. In order to cope with the emergence of aluminum plates containing other alloying elements, the International Aluminum Strip Federation specifically indicated that the 9000 series is a spare series, waiting for another new variety to fill the gap of the 9000 séria.

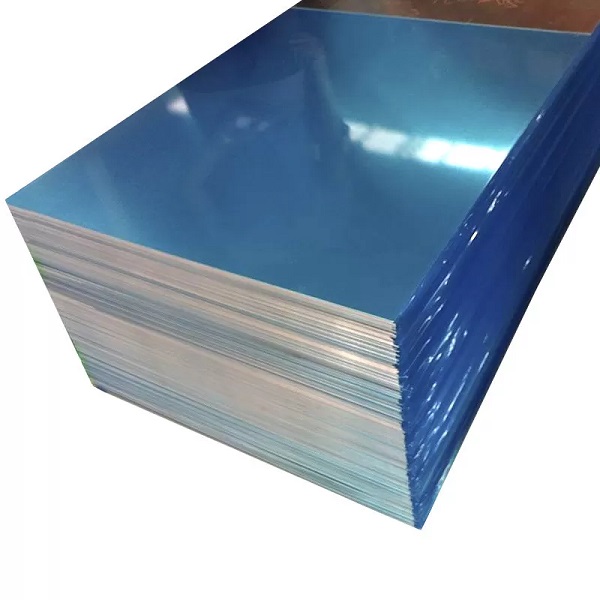

Hliníková cievka was called aluminum plates or sheets, s hrúbkou 0.2 mm až 500 mm, šírku 2600 mm, a dĺžku 16 metrov. stále viac pásikov).

Hliníková doska sa vzťahuje na pravouhlú dosku valcovanú z hliníkového ingotu, ktorý je rozdelený na dosku z čistého hliníka, zliatina hliník plech, tenká hliníková doska a stredne hrubá hliníková doska.

Hliníkové dosky sú široko používané v stavebníctve, balenie, klimatizácie, chladničky, solárna energia, kozmetiky a iných priemyselných odvetví, a možno ho použiť aj na antikoróznu ochranu a tepelnú ochranu v elektrárňach, chemické a petrochemické závody.

The raw materials of hliníková cievka are mainly pure aluminum, hot-rolled aluminum or aluminum alloy cast-rolled aluminum coils. Tieto suroviny sa vkladajú do valcovne za studena a valcujú sa do tenkých hliníkových zvitkov rôznych hrúbok a šírok, a potom sa hliníkové zvitky vložia do rezacieho stroja na rezanie. Hliníkové pásy rôznych šírok vytvorených po rozrezaní môžu hrať svoju vlastnú úlohu v skutočnej prevádzke.

There are many classifications of aluminium coil, ako napr 1050, 1060, 1070, 1100, 3003, 3004, atď. Existujú dva hlavné stavy hliníkového pásu: mäkký stav a tvrdý stav. Mäkký stav predstavuje písmeno O, a tvrdý stav je reprezentovaný písmenom H. Po dvoch písmenách je možné pridať čísla, ktoré označujú tvrdosť alebo stupeň žíhania hliníkovej cievky.

Besides, RAYIWELL can also supply prepainted aluminium coil or color coated aluminium coils with higher quality and competitive price.

What is color coated aluminium coil?

Farebne potiahnutý hliník (color coated aluminium coil), ako už názov napovedá, je vykonávať povrchovú úpravu a farebnú úpravu na hliníkovom plechu resp (hliníková cievka). Zvyčajne hliník potiahnutý fluorokarbónom (farebne potiahnutá hliníková cievka) a hliník potiahnutý polyesterovou farbou (farebne potiahnutá hliníková cievka) sú široko používané v hliníkovo-plastových paneloch, hliníkové dyhy, hliníkové plástové panely, hliníkové stropy, strešné plochy, útržky, plechovky a elektronika. Jeho výkon je veľmi stabilný a nie je ľahké ho skorodovať. Po špeciálnom ošetrení, povrch môže dosiahnuť 30 rokov zabezpečenia kvality. Jednotková objemová hmotnosť je najľahšia spomedzi kovových materiálov. Toto je nový obľúbený hliníkový profil s farebným povlakom.

-

-

-