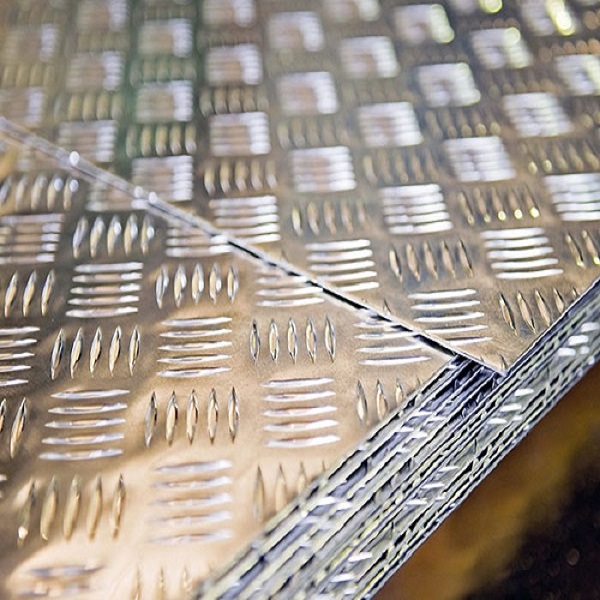

Aluminijasta kontrolna plošča, sometimes called aluminum tread plate, aluminum floor plate, or aluminum diamond plate.

Diamond aluminium tread plate or floor plate is widely used for a variety of structural, architectural and cosmetic applications.

A method has been developed to roll metal plates with an upraised “lug” vzorec, providing the customer with several choices to best meet the needs of the project, with specific qualities of cleanability, impact resistance, support strength, in odpornost proti koroziji.

Aluminijaste karo plošče 3003 in 5052 are two common alloy aluminum plates. They have certain differences in chemical composition, mehanske lastnosti, common specifications, scope of application and price.

Aluminum chequered plate 3003: It belongs to the AL-Mn series alloy. The main alloy element is manganese, and the aluminum content is slightly higher than that of 5052 aluminijaste plošče.

Aluminum tread plate 5052: It belongs to Al-Mg series alloy, and the main alloy element is magnesium.

Mehanske lastnosti

Natezno trdnost: The tensile strength of aluminum checker plate 3003 is between 145~195Rm/MPa, while the tensile strength of 5052 aluminum checker plate is as high as 230~280Rm/MPa, which is much higher than 3003 aluminijaste plošče.

Elongation strength: The elongation strength of pattern aluminum plate 3003 is 115Rm/MPa, while the elongation strength of 5052 aluminijasta tekalna plošča is 150Rm/MPa.

3003 aluminum checker plates are Mainly used in humid environments, such as product packaging, hladilniki, klimatske naprave, cold storages, ventilation ducts, etc.

Ima dobro odpornost proti koroziji, dobra varivost, and high plasticity, and is suitable for making low-load parts working in liquid or gas media.

5052 aluminij tekalne plasti plošče are commonly used in electrical casings, transportation vehicles, tlačne posode, etc. It is a common material for manufacturing automobiles and aircraft fuel tanks and oil pipes.

It has high fatigue strength and corrosion resistance, and cannot be strengthened by heat treatment. It has good weldability with resistance welding and atomic hydrogen welding.

aluminij pločevina 5052 se uporablja v številnih industrijskih aplikacijah, Z: Rezervoarji za gorivo

Primerjava z zlitino 3003, Na splošno, 3003 je precej mehak in ima dobro odpornost proti koroziji, dobra risba, dobra uporabnost, zmerna moč, in je varljiva, medtem 5052 je močnejši in ima boljšo odpornost proti koroziji, dobra risba, dobra preoblikovalnost, višja trdnost, in je tudi varljiva.

Pri žarjenju, aluminijeve zlitine 5052 je močnejši od 1100 in 3003 zlitine. Je eden najmočnejših, zlitine, ki jih ni mogoče toplotno obdelovati in ima dobro obdelovalnost. Ima tudi zelo dobro odpornost proti koroziji, predvsem v slano vodo

Velikost aluminijaste pločevine

debelina:0.2-6.0mm

Premer:100-2400mm

dolžina:200-11000mm

Matična tuljava: CC ali DC

Utež: Približno 2 mt na paleto za splošno velikost

MOQ: 5-15 ton na velikost

Zaščita: vmesni sloj papirja, beli film, modri film, črno-beli film, mikro vezan film, glede na vaše zahteve.

Površinska: čista in gladka, brez svetle pike, korozija, olje, Sinkronizirana, etc.

Standardni izdelek: GBT3880, JIS4000, EN485, ASTM-B209

Menimo, da je dolgoročno partnerstvo posledica visoke kakovosti, storitev z dodano vrednost, bogate izkušnje in osebni kontakt za .063 aluminijasta diamantna plošča,1050 1060 1100 proizvodnja aluminijastih diamantnih/karo plošč,1050 1060 3003 Aluminijasta diamantna plošča za proizvajalca protizdrsnih talnih oblog, Toplo pozdravljam stranke iz vsega sveta, za kakršno koli sodelovanje z nami za izgradnjo prihodnosti obojestransko korist. Mi smo sami namenjajo iskreno strankam ponuditi najboljše storitve.