Opis

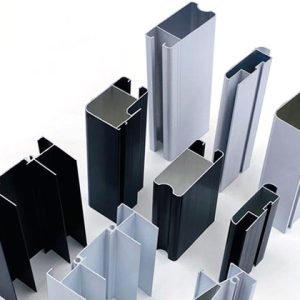

6061 in 6063 are two common types of aluminijasti profili used in various industries.

6061 aluminum profiles are known for their strength, trajnost, in odpornost proti koroziji. They are often used in applications where high strength and stiffness are required, such as aerospace, avtomobilska, and structural engineering. 6061 aluminum profiles have excellent machinability and can be easily welded, making them a popular choice for custom fabrication.

6063 aluminijasti profili, po drugi strani, are known for their excellent finishing properties and aesthetic appeal. They are often used in applications where appearance is important, such as architectural and decorative applications. 6063 aluminum profiles have good corrosion resistance and are easy to extrude, making them a popular choice for custom extrusions.

Oba 6061 in 6063 aluminijasti profili are versatile and can be used in a wide range of applications. The choice between the two depends on the specific requirements of the application, kot je moč, trajnost, and appearance.

Kot vodilni proizvajalec naprednih in visoko specializiranih profilov aluminijastih ekstruzij. Nudimo vrsto aluminijastih profilov po meri, aluminijeve ekstruzije, in veliko strukturno ekstruzijo. Aluminijasti profili so idealni za konstrukcije v strojegradnji in elektrarnah. Velika prednost je majhna teža profilov in fleksibilna tehnologija povezovanja.

6061 6063 Aluminijasti profili Proizvajalec Rayiwell MFG iz Kitajske. Aluminijasti profili lahko razdelimo na 1024, 2011, 6063, 6061, 6082, 7075 in druge vrste zlitin aluminijastih profilov, od katerega 6 serija je najpogostejša. Razlika med različnimi razredi je v tem, da je razmerje različnih kovinskih komponent različno, razen pogosto uporabljenih aluminijasti profili za vrata in okna poleg arhitekturnih aluminijastih profilov, kot so 60 serija, 70 serija, 80 serija, 90 serija, in serije zavesnih sten, za industrijske aluminijaste profile ni jasne razlike med modeli, večina proizvajalcev pa jih obdeluje po dejanskih risbah strank.

Aluminijasti profili imajo takšno površinsko obdelavo

1. Anodiziran aluminij

2. Elektroforetska prevleka aluminija

3. Prašno lakiran aluminij

4. Aluminij za prenos lesnih zrn

5. Aluminij, brizgan s fluoroogljikom

6. Poliran aluminij (delimo na mehansko poliranje in kemično poliranje, med katerimi ima kemično poliranje najvišjo ceno in najdražjo ceno)

Aluminijasti profili so izdelki, rojeni iz aluminijevih zlitin, ki se s postopkom ekstrudiranja pretvorijo v oblikovane predmete. Edinstvena kombinacija fizikalnih lastnosti aluminija je večinoma odvisna od tega procesa. Aluminijeve ekstruzije se uporabljajo na več področjih, ker je ta kovina: Močna in stabilna.

Vrste aluminijastih profilov

- Votli žarek.

- Kvadratni profil.

- SD aluminijasti profil.

- RCW profil.

- Odsek za vrata.

- Louver profil.

- T-odsek

-

Alu in Fe z Mn mg cr Zn Ti Nečistoča al Enota Skupaj 6063 0.2-0.6 <0.35 <0.1 <0.1 0.45-0.9 <0.1 <0.1 <0.1 <0.05 <0.15 Presežek 6061 0.4-0.8 0.7 0.15-0.4 <0.15 0.8-1.2 0.04-0.35 <0.25 <0.15 <0.05 <0.15 Presežek 6005 0.6-0.9 <0.35 <0.1 <0.1 0.4-0.9 0.1 <0.1 <0.1 <0.05 <0.15 Presežek 6060 0.3-0.6 0.35-0.6 0.1-0.3 <0.1 <0.1 <0.15 <0.05 <0.1 <0.05 <0.15 Presežek - Tipične uporabe 6061 Reprezentativne aplikacije vključujejo vesoljske napeljave, Električne napeljave, komunikacija, in se pogosto uporabljajo tudi v avtomatiziranih mehanskih delih, natančno obdelava, Proizvodnja plesni, Elektronika in natančni instrumenti, Smt, Vozila za spajkanje računalniških plošč, etc.

aluminij Izdelki iz aluminija in drugih legiranih elementov. Običajno se predeluje v odlitke, odkovki, folije, plošče, trakovi, cevi, palice, profili, itd, in nato obdelan s hladnim krivljenjem, žaganje, vrtanje, sestavljanje, in barvanje. Glavni kovinski element je aluminij, dodajanje nekaterih elementov zlitine za izboljšanje učinkovitosti aluminija

Aluminum profile extrusion is a manufacturing process that involves the creation of complex shapes and designs using aluminum as the primary material. The process involves forcing molten aluminum through a die, which is a specially designed tool that shapes the aluminum into the desired profile.

The aluminum profile extrusion process begins with the creation of a die, which is typically made from steel or some other durable material. The die is designed to produce the desired shape or profile of the finished product. Once the die is created, it is mounted on a press and heated to a temperature that is high enough to melt the aluminum.

The aluminum is then loaded into a hopper, which feeds it into the press. The press applies pressure to the molten aluminum, forcing it through the die. As the aluminum passes through the die, it is cooled and solidified, forming the desired shape or profile.

After the aluminum has been extruded, it is cut to the desired length and may undergo additional processing such as surface finishing, machining, or assembly. The resulting aluminum profiles can be used in a wide range of applications, vključno z gradnjo, avtomobilska, vesoljsko, and consumer products.

-

-

-