Opis

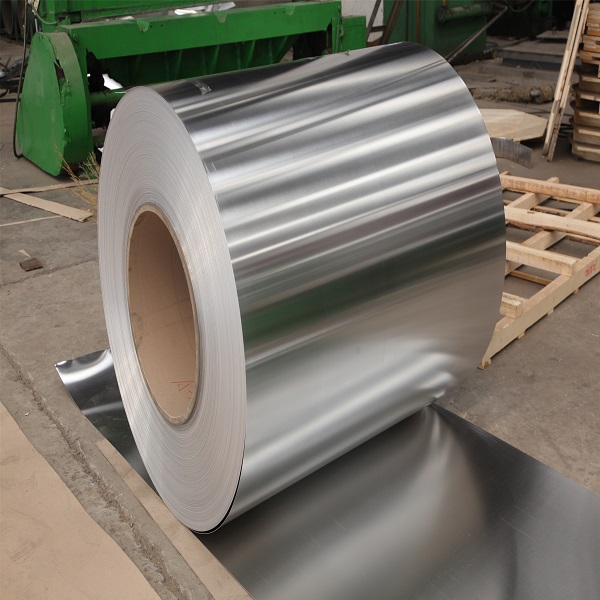

Aluminijasta tuljava je kovinski izdelek, ki je podvržen letečemu striženju, potem ko ga valjamo z vlivanjem in valjanjem ter predelamo z risanjem in upogibanjem kotov.

Aluminijasta tuljava se pogosto uporabljajo v elektroniki, embalaža, Gradnja, stroji, etc. RAYIWELL MFG / Ruiyi Aluminij kot eden od proizvajalcev aluminijastih tuljav na Kitajskem, Proizvodna tehnologija je dohitela razvite države.

According to the different metal elements contained in aluminium coil, it can be roughly divided into 9 kategorije. , ki jih je mogoče razdeliti 9 serija.

1000 serija

The representative 1000 series aluminium coil is also called pure aluminum plate. Among all the series, the 1000 series belongs to the series with the most aluminum content. The purity can reach more than 99.00%. Ker ne vsebuje drugih tehničnih elementov, proizvodni proces je razmeroma preprost, cena pa razmeroma ugodna. It is the most commonly used series in conventional industries at present. Most of the circulating in the market are 1050 in 1060 serija.

The minimum aluminum content of the 1000 serija aluminijasta tuljava is determined according to the last two Arabic numerals. na primer:, the last two Arabic numerals of the 1050 serije so 50. Po mednarodnem principu poimenovanja blagovnih znamk, the aluminum content must reach 99.5% or more to qualify as a product. my country’s aluminum alloy technical standard (gB/T3880-2006) also clearly stipulates that the aluminum content of 1050 should reach 99.5%. In the same way, vsebnost aluminija 1060 series aluminum plates must reach more than 99.6%.

2000 serije aluminijaste plošče

Representative 2A16 (LY16) 2A06 (LY6) 2000 series aluminum plate is characterized by high hardness, among which the content of copper is the highest, o 3-5%. The 2000 series aluminum plate belongs to aviation aluminum, which is not commonly used in conventional industries. There are fewer manufacturers of 2000 series aluminum sheets in my country.

3000 serije aluminijaste plošče

Rep. 3003 3003 3A21-based. It can also be called anti-rust aluminum plate. The production process of 3000 series aluminum plate in China is relatively excellent. The 3000 series aluminum plate is mainly composed of manganese. The content is between 1.0-1.5. It is a series with better anti-rust function. Routinely used in humid environments such as air conditioners, hladilniki, and undercars, the price is higher than the 1000 serija, and it is a more commonly used alloy series.

4000 serija aluminijaste plošče

The aluminum plate represented by 4A01 4000 series belongs to the series with higher silicon content. Usually the silicon content is between 4.5-6.0%. It belongs to building materials, mehanski deli, forging materials, welding materials; low melting point, good corrosion resistance Product description: Has the characteristics of heat resistance and wear resistance.

5000 serija

Represents the 5052.5005.5083.5A05 series. The 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy.

The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series. zato, it is often used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries. The processing technology is continuous casting and rolling, which belongs to the series of hot-rolled aluminum plates, so it can be used for oxidation deep processing.

6000 serija

It means that 6061 mainly contains magnesium and silicon, so the advantages of 4000 serije in 5000 series are concentrated. 6061 is a cold-processed aluminum forged product, suitable for applications requiring high corrosion resistance and oxidation resistance. Good workability, excellent interface characteristics, easy coating, good processability. Can be used on low pressure weapons and aircraft connectors.

General characteristics of 6061: excellent interface characteristics, easy coating, visoka moč, dobra uporabnost, and strong corrosion resistance.

Typical uses of 6061 aluminij: deli letal, camera parts, couplers, marine accessories and hardware, electronic accessories and joints, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts .

7000 serija

On behalf of 7075 mainly contains zinc. It also belongs to the aviation series. It is an aluminum-magnesium-zinc-copper alloy. It is a heat-treatable alloy. It belongs to superhard aluminum alloy and has good wear resistance.

The thick 7075 aluminum plate is all ultrasonically detected, which can ensure no blisters and impurities.

The high thermal conductivity of the 7075 aluminum plate can shorten the forming time and improve work efficiency.

The main feature is that the hardness is high. 7075 is a high-hardness, high-strength aluminum alloy, which is often used in the manufacture of aircraft structures and futures. It requires high-stress structural parts with high strength and strong corrosion resistance, and mold manufacturing.

8000 serija

The more commonly used is 8011 which belongs to other series. In my memory, the aluminum plate is mainly used as a bottle cap, and it is also used in radiators, most of which are aluminum foil. Not very commonly used.

9000 serija

It belongs to the spare series, and the technology is so advanced. In order to cope with the emergence of aluminum plates containing other alloying elements, the International Aluminum Strip Federation specifically indicated that the 9000 series is a spare series, waiting for another new variety to fill the gap of the 9000 serija.

Aluminijasta tuljava was called aluminum plates or sheets, z debelino 0.2 mm do 500 mm, širina 2600 mm, in dolžina 16 metrov. Vedno več trakov).

Aluminijasta plošča se nanaša na pravokotno ploščo, valjano iz aluminijastega ingota, ki je razdeljen na ploščo iz čistega aluminija, aluminijeve zlitine ploščo, tanka aluminijasta plošča in srednje debela aluminijasta plošča.

Aluminijaste plošče se pogosto uporabljajo pri gradbeništvu, embalaža, klimatske naprave, hladilniki, sončna energija, kozmetika in druge panoge, in se lahko uporablja tudi za protikorozijo in ohranjanje toplote v elektrarnah, kemične in petrokemične rastline.

The raw materials of aluminijasta tuljava are mainly pure aluminum, hot-rolled aluminum or aluminum alloy cast-rolled aluminum coils. Te surovine se dajo v hladno valjanje in se valjajo v tanke aluminijaste tuljave različnih debeline in širine, In potem se aluminijaste tuljave dajo v rezalni stroj za rezanje. Aluminijasti trakovi različnih širine, nastale po rezanju, lahko v dejanskem delovanju igrajo svoje vloge.

There are many classifications of aluminium coil, kot naprimer 1050, 1060, 1070, 1100, 3003, 3004, etc. Obstajata dve glavni državi aluminijastega traku: mehko in trdo stanje. Mehko stanje je predstavljeno s črko o, in trdo stanje je zastopano s črko H. Številke lahko dodate po dveh črkah, da označite trdoto ali žarjenje stopnje aluminijaste tuljave.

Besides, RAYIWELL can also supply prepainted aluminium coil or color coated aluminium coils with higher quality and competitive price.

What is color coated aluminium coil?

Aluminij z barvno prevleko (color coated aluminium coil), kot pove že ime, je izvesti površinsko prevleko in obdelavo barvanja na aluminijasti plošči oz (aluminijasta tuljava). Običajno aluminij, prevlečen s fluoroogljikom (Barvno prevlečena aluminijasta tuljava) in poliestrski barvni prevlečen aluminij (Barvno prevlečena aluminijasta tuljava) se pogosto uporabljajo na aluminijastih plastičnih ploščah, Aluminijasti furnirji, Plošče iz aluminija, Aluminijasti stropi, strešne površine, ostanki, pločevinke in elektronika. Njegova zmogljivost je zelo stabilna in ga ni enostavno korodirati. Po posebnem zdravljenju, površina lahko doseže 30 leta zagotavljanja kakovosti. Volumen volumna je najlažja med kovinskimi materiali. To je nov priljubljen profil z aluminijasto barvo.

-

-

-