Опис

5454 Алуминијска плоча је типична алуминијумска алуминијум. Његова снага је отприлике иста као 5154, О томе 20% веће од оне 5052 алуминијум.

The 5454 Алуминијум развијености развијено је за употребу у производњи Алуминијумске листове у резервоар, суве скупне приколице и тела за одлагање. Легура алуминијума 5454 има врло добру отпорност на корозију, посебно на морске и опште услове заштите животне средине.

Алтер 5454 је не-топлота легура алуминијума и магнезијума. То је умерена легура снаге која се може очврснути (ојачан) хладном радом

легура 5454 алуминум плате се широко користи у производњи резервоара за складиштење хемијских производа, Аутомобилски точкови и посебно оне апликације које могу бити подлеже температурама у вишку од 150 ° Ф.

Алуминијумско име:

1000 серија:1050,1060,1070,1080,1100,1145,1200,1235, итд.

2000 серија:2014,2017,2018,2024,2025,2219, 2219,2618а итд.

3000 серија:3003,3004,3102,3104,3105,3005, итд.

4000 серија:4032,4043, 4017, итд

5000 серија: 5005,5052,5454,5754,5083,5086,5182,5082, итд.

6000 серија:6061,6063,6262,6101, итд

7000 серија:7072,7075,7003 итд

8000 серија: 8011, итд.

Величина алуминијумског лима

дебљина:0.2-6.0мм,

ширина:100-2400мм,

дужина:200-11000мм,

Мотхер цоил: ЦЦ или ДЦ

тежина: Око 2мт по палети за општу величину

МОК: 5-15 тона по величини

Заштита: папир међу слојевима, бели филм, плави филм, црно-бели филм, микро везани филм, према Вашем захтеву.

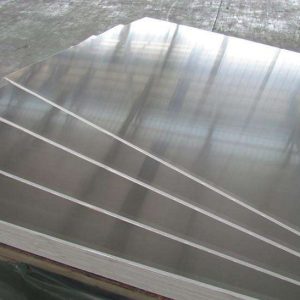

површина: чиста и глатка, нема светле тачке, корозија, уље, прорезати, итд.

Стандардни производ: ГБТ3880, ЈИС4000, ЕН485, АСТМ-Б209

Време испоруке: око 30 дана након пријема депозита

Бити без мрље уља, Удубљење, Укључивање, Огреботине, Мрљати, Оксидалоско уклањање, Паузе, Корозија, Ролне ознаке, Прљавштине и друга оштећења која ће се ометати употреби

Површина без црне линије, чист рез, периодична мрља, Дефекти за штампање ваљка, као што су други стандарди интерне контроле.

Не можете видети никакав мален простор између плоча када су нагомилани. А површина је глатко без пеге.

Имамо строге и професионалне процедуре производње:

(1)Пре израде :

Осигурање усаглашености стандарда и материјала према налогу купца;

Израда плана производње према налогу купца ;

Покретање производње након пријема уплате купца

(2)Завршена производња :

Хемијски тест и механички тест од стране нашег одељења за квалитет, Визуелни преглед

Мерење дебљине (Континуирани ултразвучни)

Контрола димензије дужине.

Равност,Равност,Визуелни & Провера димензије ивице

Контрола тежине

Обележавање

(3)Провера пре испоруке :

Провера пакета

Потврда о усаглашености

Провера марке и количине испоруке

-

-

-