Опис

6061 aluminijumska плоча Manufacturer RAYIWELL MFG supply aluminum-silicon-magnesium alloy, strengthened by precipitation hardening. This alloy has medium strength, Обрадивост, способност заваривања, Обрадљивост и корозију отпорност.

aluminijumska плоча 6061 T6 temper has an ultimate tensile strength of at least 42,000 psi (290 Мпа) and yield strength of at least 35,000 psi (241 Мпа). In thicknesses of 0.250 inch (6.35 мм,) or less, it has elongation of 8% или више; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties.

легура 6061 alumium plate has a relatively high strength, easily welded and is widely used not only for making bicycle frames, but also in construction, авион, shipbuilding.

The main alloying elements in 6061 алуминум плате are magnesium and silicon, са умереном снагом, добра отпорност на корозију, weldability and oxidation effect. Widely used in various industrial structures requiring certain strength and high antibiotic corrosion resistance.

The main chemical components are: бакар 0.15-0.4%, силицијум 0.4-0.8%, гвожђе 0.7%, манган 0.15%, магнезијум 0.8-1.2%, цинк 0.25%, chromium 0.04-0.35%, титанијум 0.15%.

The difference between 6061 алуминум плате T6 and T651 is that, under normal circumstances, the internal stress of T6 will be relatively large, and it will be deformed during processing. The most suitable state for processing should be T651, stretched on the basis of T6, and eliminate internal stress.

6061-Т6 : cooling after solution heat treatment to achieve high strength, no cold working;

6061-Т651 : Cooling after solution heat treatment to achieve high strength, and then cold stretching by stretching machine to eliminate residual internal stress after heat treatment, so as to ensure the precision of machined products without deformation after deep processing.

6061 Т6 алуминијум Plate is a commonly used aluminum alloy. Unless otherwise specified, it is generally in the 6061 Т6, и 6061 T651 is the best feature of the 6-series aluminum alloy, and it is a fighter in the 6000-series алуминијум легура. It has excellent processing performance, excellent welding characteristics and electroplating performance, добра отпорност на корозију, high toughness, no deformation after processing, dense material without defects, easy polishing, easy coloring and film formation and excellent oxidation effect.

Since 6061-T651 is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process, although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, excellent processing performance and excellent welding Features and electroplating, добра отпорност на корозију, high toughness and no deformation after processing, compact material without defects and east to polish, easy to color film, excellent oxidation effect and other excellent characteristics. The representative applications of 6061-T651 include aerospace fixtures, електричне инсталације, and communication fields, а такође се широко користе у аутоматизованим механичким деловима, прецизна обрада, производња калупа, електронике и прецизних инструмената, СМТ, PC board solder carriers, итд.

The states of 6061 алуминијумски лимови are O temper, Т4, Т6, Т651, итд. For different states, the application fields are different. 6061 aluminum plate has high strength, good anti-corrosion and anti-oxidation effects, and is widely used in automatic mechanical parts, прецизна обрада, automobile chassis, cake molds, итд, and is deeply loved by users.

Both the 6061-T6 алуминум плате and the 6061-T651 aluminum plate are commonly used. The difference between the T6 state of the 6061 aluminum plate and the T651 is:

The internal pressure of T6 is high, and the processing deformation is more suitable for processing. The state is T651, which eliminates internal stress on the basis of T6 extension. The main alloy elements of 6061 aluminum plate are magnesium and silicon, which have medium strength, високе чврстоће, weldability and good oxidation effect.

темперамент: T1,T2,T3, Т4, Т6, Т651

дебљина:0.2-350мм,

ширина:30-2600мм,

дужина:200-11000мм,

Мотхер цоил: ЦЦ или ДЦ

тежина: Око 2мт по палети за општу величину

МОК: 5-10тона по величини

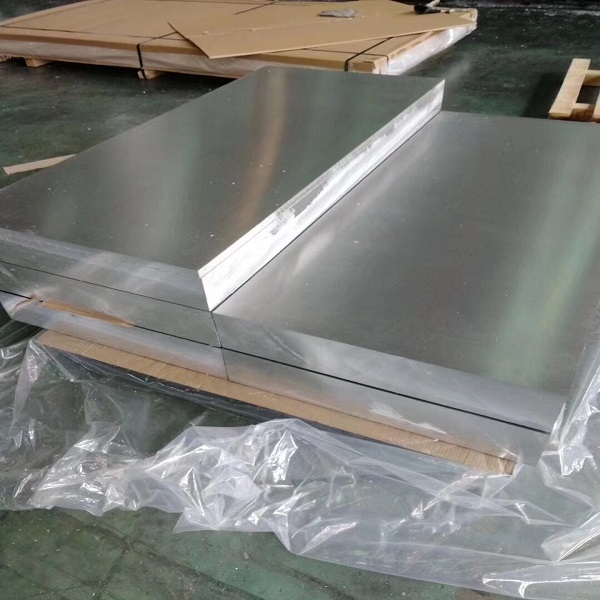

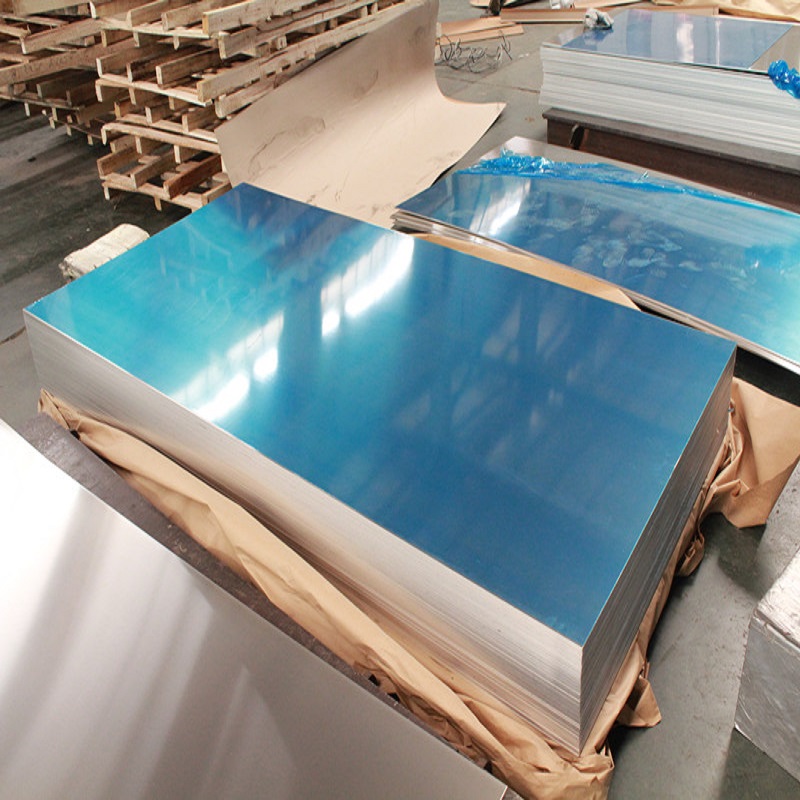

Заштита: папир међу слојевима, бели филм, плави филм, црно-бели филм, микро везани филм, према Вашем захтеву.

површина: чиста и глатка, нема светле тачке, корозија, уље, прорезати, итд.

Стандардни производ: ГБТ3880, ЈИС4000, ЕН485, АСТМ-Б209, ЕН573, ASTMB221, AMS-QQ-A-200/8, ASMESB221

Време испоруке: око 30 дана након пријема депозита

Плаћање: Т/Т, Л / Ц по виђењу

Услови трговања: ФОБ, ЦИФ, ЦФР

други алуминум плате alloy available

1000 серија:1050,1060,1070,1080,1100,1145,1200,1235, итд.

2000 серија:2014,2017,2018,2024,2025,2219, 2219,2618а итд.

3000 серија:3003,3004,3102,3104,3105,3005, итд.

4000 серија:4032,4043, 4017, итд

5000 серија: 5005,5052,5454,5754,5083,5086,5182,5082, итд.

6000 серија:6061,6063,6262,6101, итд

7000 серија:7072,7075,7003 итд

8000 серија: 8011, итд.

Алуминијумски лим or aluminum plate is used in construction material and building material. Укључујући: кровна плоча, плафон, у зиду, преградни зид, капци, ролетна, капија,

балкон, зид, обележавање пута, улични знакови, плоча за заштиту пута, заштитна плоча за аутопут, носећи зид моста, скела, бродска плоча, итд.

Алуминијумски лим се користи у компонентама електричних машина. Укључујући: заштитна плоча, заштитна кутија, кондензаторска кутија, резервоар снаге кондензатора, електролитички кондензатор, променљива батерија, запреминска осовина, оквир звучника, прекидач плоча, полупроводнички радијатор, магнетни диск, оквир мотора, пакао оставља, електрични шпорет, расхладна пера, топлотни издув, итд

-

-

-