Maelezo

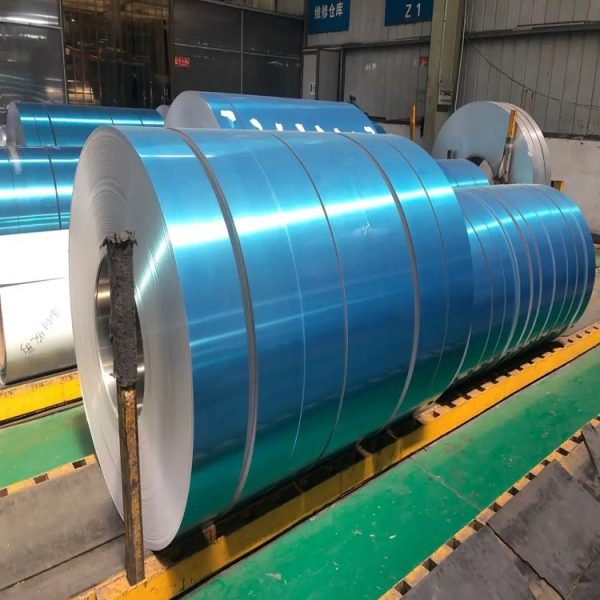

RAYIWELL MFG / TOP Metal Manufacture can supply Fuel Tank aluminum Plate 5052 aluminium Coil, which belongs to the aluminum-magnesium alloy. According to the thickness, it can be divided into 5052 thin plate, 5052 medium and thick plate.

5052 aluminum alloy Plate belongs to the Al-Mg series alloy and has a wide range of applications, especially the construction industry is inseparable from this alloy. It is one of the most promising alloys. Good corrosion resistance, weldability bora, good cold workability, and medium strength. The main alloy element of 5052 aluminum alloy is magnesium, which has good formability, upinzani kutu, weldability, and medium strength. It is used to manufacture aircraft fuel tanks, mabomba ya mafuta, and sheet metal parts for transportation vehicles and ships, vyombo, street lamp brackets and Rivets, bidhaa za vifaa, electrical-apparatus casings, na kadhalika.

5052 Aluminium coil is the most widely used anti-rust aluminum. This alloy has high strength, hasa upinzani wa uchovu: plastiki ya juu na upinzani wa kutu, and cannot be strengthened by heat treatment. Low plasticity when hardened, nzuri ulikaji upinzani, weldability nzuri, poor machinability, and can be polished. Mainly used for low-load parts that require high plasticity and good weldability, working in liquid or gaseous media, such as fuel tanks, gasoline or lubricating oil conduits, various liquid containers and other small-load parts made by deep drawing: The wire is used to make rivets.

5052 sahani ya alumini na 6061 aluminum plate are our commonly used aluminum plates. The element of 5052 is magnesium, while the element of alloy 6061 contains silicon in addition to magnesium. Zaidi ya hayo, the processing state is different, except that the 6061 aluminum plate and the 5052 aluminum plate are both in the O temper, the 6061 aluminum plate is generally in the temper of T6 and T651, and the 5052 aluminum plate is generally in the temper of H112, H24, H32.

Mechanical properties of 5052 aluminum plate Tensile strength σb (MPA): ≤225 Elongation δ5 (%): ≥10 Mechanical properties of 6061 aluminum plate Tensile strength σb (MPA): ≥180 Yield point σ0.2 (MPA): ≥110 elongation Length δ5 (%): ≥14

The 5052 aluminum plate can be bent, and the 6061 aluminum plate has high hardness and is generally used for grinding tools. Both of them have good oxidation effect.

5052 sahani alumini has a wide range of applications, has fatigue resistance, plastiki ya juu na upinzani wa kutu, can not be strengthened by heat treatment, and has good plasticity, low cold working plasticity, nzuri ulikaji upinzani, weldability nzuri, poor machinability, and can be polished. 6061 aluminum plate has good corrosion resistance, weldability and good oxidation effect. Widely used in various industrial building parts that require certain strength and high corrosion resistance. 6061 aluminum plate is mainly used in places with high strength requirements, wakati 5052 aluminum plate is a kind of anti-rust aluminum alloy, which is mainly used in environments with anti-rust requirements.

5052 is an Al-Mg series anti-rust aluminum alloy, which cannot be strengthened by heat treatment. The chemical composition of this alloy is similar to that of 5A02 alloy, and its performance is basically the same as that of 5A02.

5052 aluminum alloy plate is used for parts that require good formability and corrosion resistance, high fatigue limit, weldability nzuri, and medium static load, such as aircraft fuel and oil conduits, matangi ya mafuta, and various marine and land transportation equipment parts, cold stamping parts, sheet metal artifacts, street lamp posts; materials used as rivets or welding rods.

H32 and H112 are aluminum alloy tempers.

H32: Stabilized 1/4 hard temper after work hardening.

H112: Applicable to hot-formed products, the mechanical properties of this temper have specified requirements

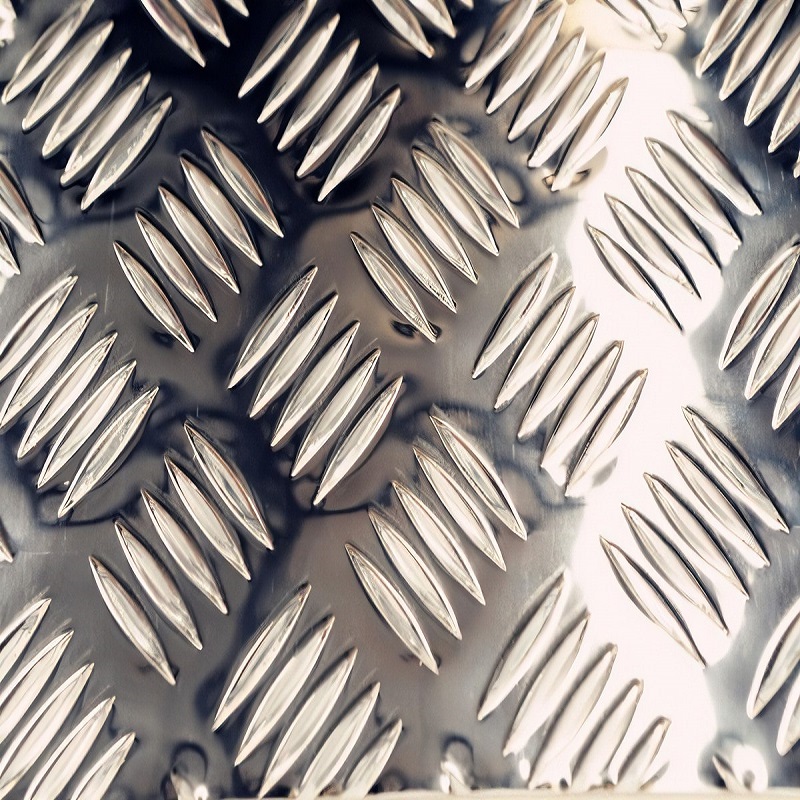

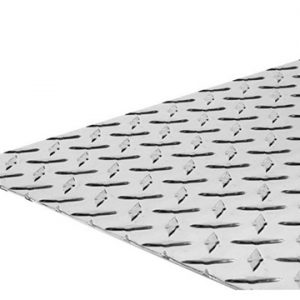

The aluminum-magnesium alloy checker pattern plate is processed from 5000 series aluminum plate such as 5052, which has good processability, high hardness and excellent rust resistance. It is generally used in occasions that require corrosion resistance and load-bearing capacity, such as ship decks, anti-slip carriages, anti-slip stairs, na kadhalika. This kind of aluminum plate has high hardness and has a certain load-bearing capacity.

The five-bar non-slip patterned aluminum plate has become a willow-shaped patterned plate. It has good anti-skid ability and is widely used in the design of construction (sakafu) platforms. Since the patterns on the surface of the aluminum plate are arranged in parallel according to five concave-convex patterns, and the angle between each pattern and other patterns is 60-80 degrees, this pattern has excellent anti-skid performance. This kind of aluminum plate is usually used as anti-slip in China, which has good anti-slip effect and is slightly cheaper.

Specifications of 5052 patterned aluminum plate:

unene (mm)0.8-8.0

upana (mm) 100-1850

Muda (mm) 500-16000

The main purpose of the checkered aluminum plate is anti-slip and decoration. It is often used in special places such as cold storage, meli, carriages, ngazi, na kadhalika.; zaidi ya hayo, it is widely used in furniture, such as refrigerators, air conditioners, carriages, platforms, packaging pipes, screen skeletons, and various suspension beams. , table legs, decorative strips, handles, wiring troughs and covers, chair tubes, na kadhalika.

3003 5052 alumini sahani checkered

As aluminum coil factory in China, we are looking forward to forming successful business relationships with new clients around the world in the near future.Our eternal pursuits are the attitude of ,kuzingatia soko, kuzingatia desturi, kuzingatia sayansi, na nadharia ya ,ubora wa msingi, mwamini wa kwanza na usimamizi wa hali ya juu, kwa , sasa tunatarajia ushirikiano mkubwa zaidi na wateja wa ng'ambo kwa kuzingatia faida za pande zote. Kama una nia yoyote ya bidhaa zetu, please feel free to contact us for more detail.

-

-

-