ลักษณะ

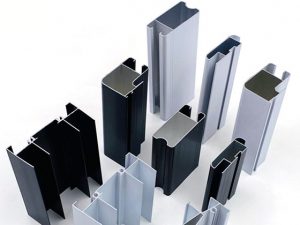

Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross sectional profile. A powerful ram pushes the aluminum through the die and it emerges from the die opening. When it does, it comesout in the same shape as the die and is pulled out along a runout table.

Aluminum extrusions are used as components in many different devices, equipment, and systems, such as those found in aircraft, the International Space Station (ISS),อิเล็กทรอนิกส์, แพทย์,กีฬาและสันทนาการ.

Aluminum extrusion profiles are ideal for use across a range of industries. Our American-made products are strong, น้ำหนักเบา, durable and compliant with the Restriction of Hazardous Substances Directive (RoHS).

อลูมิเนียม is ideal for use in the manufacture of components for medical equipment, such as hospital beds and testing devices. นอกจากนี้, aluminum extrusions can be made to tight tolerances, which allows them to meet the industry’s strict standards

According to different classification principle, there are many types of common aluminum alloys.

ประการแรก, common aluminum alloys are divided into 8 aluminium alloy series according to different chemical composition;

ในประการที่สอง, on the base of aluminium material grade, อลูมิเนียม alloy tempers are more fine classification, mainly including O, H, F, W and T tempers. The Numbers behind these five aluminium alloy temper designations represent different processing degrees;

Thirdly, recrystallization temperature as the cut-off point, the above is heat-treatable aluminum alloy, the following is the non-heat-treatable aluminum alloy;

Fourthly, according to different processing methods, common aluminum alloys can be divided into cast aluminum alloys and wrought aluminium alloys;

Sixthly, according to different sources of raw materials, primary aluminum is mined from aluminum ore, while regenerated aluminum is reprocessed by waste aluminum and scrap aluminum;

ในที่สุด, according to aluminium alloy properties and uses, common aluminum alloys can be divided into aerospace aluminium alloys, marine aluminum alloys, construction aluminum alloys, decoration aluminum alloys and so on.

-

-

-