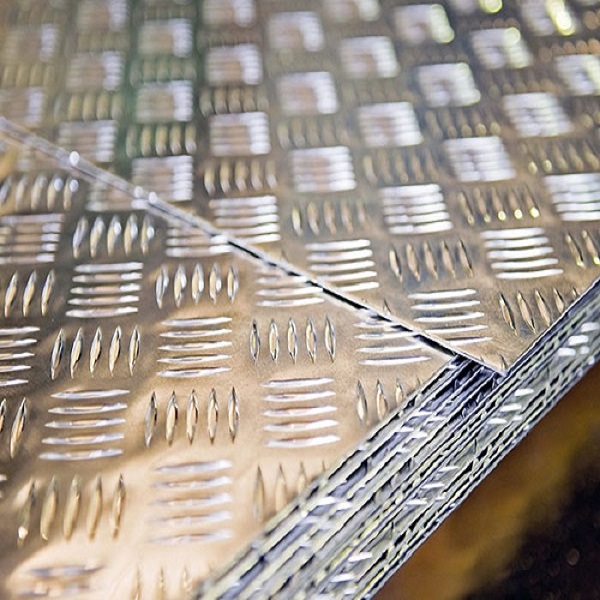

Aluminum checker plate, Minsan tinatawag na aluminyo pagtapak ng plato, aluminyo plate plate, o aluminyo na plato ng brilyante.

Ang brilyante na aluminyo na tread plate o plate ng sahig ay malawakang ginagamit para sa iba't ibang istruktura, architectural and cosmetic applications.

A method has been developed to roll metal plates with an upraised “lug” padron, providing the customer with several choices to best meet the needs of the project, with specific qualities of cleanability, impact resistance, support strength, at paglaban ng kaagnasan.

Aluminum checker plates 3003 at 5052 are two common alloy aluminum plates. They have certain differences in chemical composition, mechanical properties, common specifications, scope of application and price.

Aluminum chequered plate 3003: It belongs to the AL-Mn series alloy. The main alloy element is manganese, and the aluminum content is slightly higher than that of 5052 aluminyo plate.

Aluminum tread plate 5052: It belongs to Al-Mg series alloy, and the main alloy element is magnesium.

Mechanical properties

Tensile strength: The tensile strength of aluminum checker plate 3003 is between 145~195Rm/MPa, while the tensile strength of 5052 aluminum checker plate is as high as 230~280Rm/MPa, which is much higher than 3003 aluminyo plate.

Elongation strength: The elongation strength of pattern aluminum plate 3003 is 115Rm/MPa, while the elongation strength of 5052 plate plate ng aluminyo is 150Rm/MPa.

3003 aluminum checker plates are Mainly used in humid environments, such as product packaging, refrigerators, air conditioners, cold storages, mga duct ng bentilasyon, etc.

It has good corrosion resistance, good weldability, and high plasticity, and is suitable for making low-load parts working in liquid or gas media.

5052 aluminum tread plates are commonly used in electrical casings, transportation vehicles, presyon ng sasakyang-dagat, etc. It is a common material for manufacturing automobiles and aircraft fuel tanks and oil pipes.

It has high fatigue strength and corrosion resistance, and cannot be strengthened by heat treatment. It has good weldability with resistance welding and atomic hydrogen welding.

Aluminum sheet 5052 ay ginagamit sa maraming uri ng pang-industriyang aplikasyon, kabilang: Tangke ng gasolina

Paghahambing sa haluang metal 3003, Sa pangkalahatan, 3003 ay medyo malambot at may magandang corrosion resistance, magandang drawing, magandang workability, katamtamang lakas, at weldable, habang 5052 ay mas malakas at may mas mahusay na paglaban sa kaagnasan, magandang drawing, magandang formability, mas mataas na lakas, at din ay weldable.

Kapag annealed, aluminyo haluang metal 5052 ay mas malakas kaysa sa 1100 at 3003 alloys. Ito ay isa sa mas mataas na lakas, non-heat-treatable alloys at may magandang workability. Mayroon din itong napakahusay na paglaban sa kaagnasan, lalo na sa tubig-alat

Sukat ng aluminum sheet

kapal:0.2-6.0mm

lapad:100-2400mm

haba:200-11000mm

Ina coil: CC o DC

timbang: Mga 2mt bawat papag para sa pangkalahatang sukat

MOQ: 5-15 tonelada bawat laki

Proteksyon: papel inter layer, puting pelikula, asul na pelikula, itim-puting pelikula, micro bound na pelikula, ayon sa iyong mga kinakailangan.

ibabaw: malinis at makinis, walang maliwanag na batik, kaagnasan, langis, slotted, etc.

Karaniwang produkto: GBT3880, JIS4000, EN485, ASTM-B209

Naniniwala kami na ang pangmatagalang partnership ay resulta ng mataas na kalidad, serbisyong idinagdag sa halaga, rich experience and personal contact for .063 plato ng diamante ng aluminyo,1050 1060 1100 paggawa ng sheet ng aluminyo na brilyante / tsek,1050 1060 3003 Ang Plato ng Sheet ng Aluminyo para sa Anti-Slip Floor Manufacturer, Malugod naming tinatanggap ang mga customer mula sa buong mundo para sa anumang uri ng pakikipagtulungan sa amin upang makabuo ng hinaharap na pakinabang sa isa't isa. Buong puso naming iniaalay ang aming mga sarili upang mag-alok sa mga customer ng pinakamahusay na serbisyo.