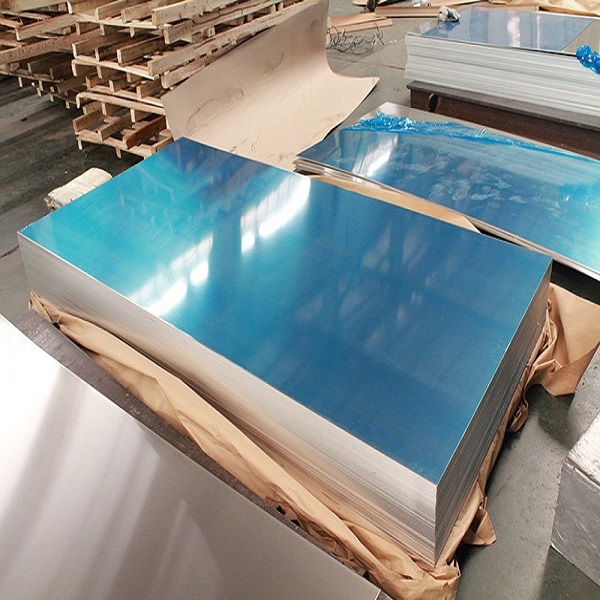

paglalarawan

Anodized aluminum sheet is a special metal product made through electrochemical reaction. During the production process, the aluminum sheet is placed in the corresponding electrolyte (tulad ng sulpuriko acid, kromiko acid, okselik acid, at iba pa) as an anode, and electrolysis is performed under specific conditions and the action of external current.

After electrolysis, an aluminum oxide film will form on the surface of the aluminum plate. Its thickness is usually between 5 at 20 microns, and the hard anodized film can reach 60 sa 200 microns. This oxide film not only improves the hardness and wear resistance of the aluminum plate, but also gives it good heat resistance, insulation and corrosion resistance.

Anodized aluminum sheet are widely used in many fields, including construction, home furnishing, electronics, mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, machine casings, lamp lighting, consumer electronics, handicrafts, household appliances, panloob na dekorasyon, Signage, kasangkapan, car decoration, etc.

|

baitang

|

1050, 1060, 1070, 1100, 5050, 5052

|

|

Surface finish

|

Color Anodized

Reflective Mirror (Powder) Coated brushed (Anodized) Sandblasted (Anodized) |

|

Kulay

|

Ecru, itim, Blue, Gold, Sliver, pula, Rose-gold, custom

|

|

Sheet Size(mm)

|

330*625, 610*406, 1220*2440, Custmized

|

|

kapal(mm)

|

0.3-10mm, standard: 0.5mm, 0.6mm, 0.8mm, 1.0mm, 2.0mm, etc

|

Anodized aluminum sheet offer a variety of features and benefits. First of all, it has strong corrosion resistance and can effectively extend its service life. ikalawa, as the base material, the aluminum plate itself has good fire resistance and can effectively prevent the spread of flames.

At saka, anodized aluminyo plates also have the characteristics of good processability, paglaban sa panahon, strong metallic feel, strong stain resistance and strong applicability. It is easy to bend and form and perform high-speed stamping, and can be directly processed into products, which greatly reduces the product production cycle and cost.

Kasabay nito, its surface has high hardness, good scratch resistance, no paint coverage, retains the metallic color of the aluminum plate, and enhances the grade and added value of the product.

We are a leading supplier of pad printing plates (clichés) for all pad printing machinery. We supply several types of pad printing plates:

- Laser engravable pad printing plates

- Alcohol washable polymer pad printing plates

- Water washable polymer pad printing plates

- Steel pad printing plates in both thin and thick steel

All of our plates can be delivered in any size required. at, kung kinakailangan, fitted with punched holes for any pad printing machine in the market.

Anodized aluminum sheet or Pad printing aluminum cliché is a technique used in the pad printing process, which is a method of transferring an image or design onto a surface.

An aluminum cliché is a plate or pad that is made from aluminum and has the desired image or design etched or engraved onto its surface. The cliché is then coated with ink, and a silicone pad is pressed onto the cliché, picking up the ink from the etched areas.

The silicone pad is then pressed onto the surface to be printed, transferring the ink onto the desired object. This process allows for precise and detailed printing on various materials, including aluminum.

Aluminum clichés are preferred in pad printing due to their durability, as they can withstand repeated use without wearing down or losing their shape. They also provide excellent ink transfer, resulting in high-quality prints.

To create an aluminum cliché, a design or image is first created digitally or drawn by hand. The design is then transferred onto a photosensitive coating applied to an aluminyo plate. This coated plate is exposed to UV light, which hardens the coating in the areas where the image is present.

After exposure, the unhardened coating is washed away, leaving behind a relief of the design on the aluminum plate. The plate is then treated with an etching solution to deepen the relief and ensure proper ink transfer.

10 Tips for Printing anodized Aluminum sheet

1. Use high-quality aluminum plates specifically designed for printing purposes to ensure the best results.

2. Clean the aluminum plates thoroughly before printing to remove any dust, dirt, or oil that could affect the printing quality.

3. Use the right type of ink for aluminum printing, such as UV-curable or solvent-based inks, to ensure good adhesion and durability.

4. Adjust the printing press settings, such as pressure and speed, to achieve the best print quality on aluminum plates.

5. Use a high-resolution image or design for printing to ensure sharp and clear results on the aluminum plates.

6. Test print on a small piece of aluminum first to check the color accuracy and quality before printing on a larger scale.

7. Use proper drying and curing techniques to ensure the ink adheres well to the aluminum surface and is fully cured for durability.

8. Handle the aluminum plates with care to avoid scratching or damaging the printed surface during and after printing.

9. Consider using a protective coating or laminate to enhance the durability and longevity of the printed aluminum plates.

10. Regularly maintain and clean the printing equipment to ensure consistent and high-quality printing results on aluminum plates.

-

-

-