paglalarawan

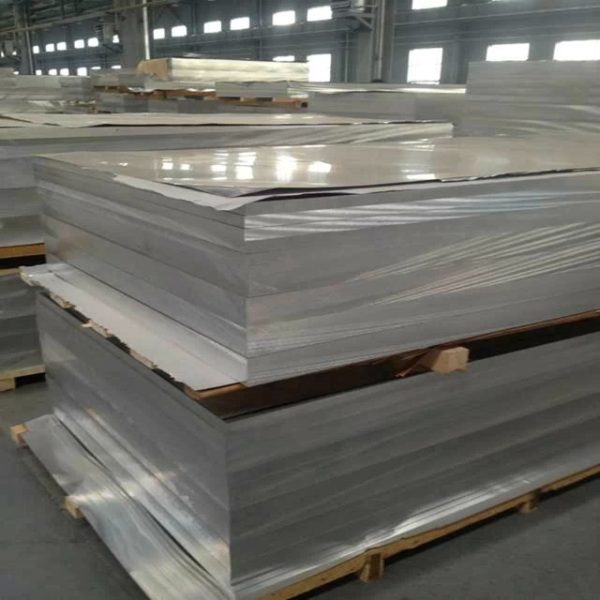

7075 aluminum alloy supplier RAYIWELL is a professional factory of aluminum sheet, aluminum bar, or aluminum plate in China.

Aluminium Coil Aluminum Plate Sheet Supplier RAYIWELL MFG / RUIYI can offer aluminum sheet grade below

1000 serye:1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 serye:2014,2017,2018,2024,2025,2219, 2219,2618a atbp.

3000 serye:3003,3004,3102,3104,3105,3005, etc.

4000 serye:4032,4043, 4017, etc

5000 serye: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 serye:6061,6063,6262,6101, etc

7000 serye:7072,7075,7003 etc

7075 aluminum alloy is a cold-processed forged alloy with high strength, much better than mild steel. 7075 is one of the strongest alloys commercially available. General corrosion resistance, good mechanical properties and anodic reaction. Fine grains allow for better deep drilling performance, enhanced tool wear resistance and distinctive thread rolling.

7050 is a high-strength heat-treatable alloy with extremely high strength and resistance to spalling corrosion and stress corrosion cracking. Commonly used in aircraft structural parts for medium and thick plates, extruded parts, free forging parts and die forging parts.

7075 aluminyo plate is an Al-Zn-Mg-Cu series superhard aluminum. 7075 alloy is an ultra-high strength deformed aluminum alloy widely used in the aviation industry. It is characterized by good plasticity after solution treatment and particularly good heat treatment strengthening effect. It has high strength below 150℃, and has particularly good low-temperature strength. The plasticity in the annealed and freshly quenched states is slightly lower than that of 2A12 in the same state. It is slightly better than 7A04. The plate is static fatigue and notch sensitive, and has excellent stress corrosion properties. Among 7A04, 7075T651 is particularly top-grade and is known as the best product among aluminum alloys. It has high strength and is far better than mild steel. This alloy has good mechanical properties and anodic reaction, and is a typical aviation aluminum.

ang 7075 varieties are divided into plates, thick plates, stretched tubes, extruded tubes, rods, shapes, rows, wire rods, rolled or cold-processed bars, and cold-processed wire rods. The states include O state, T6 state, T651 state, T6511 state, T73 state, T7351 state, T7651 state, T76511 state, and H13 state.

Typical uses of 7075 aluminum are aerospace industry, blow molding (bottle) molds, ultrasonic plastic welding molds, golf ball heads, shoe molds, paper molds, foam molding molds, dewaxing molds, templates, fixtures, mechanical equipment, mold processing and other corrosion-resistant high-stress structural parts

Zinc is the main alloy element in 7075. Adding magnesium to an alloy containing 3%-7.5% zinc can form MgZn2 with significant strengthening effect, making the alloy’s heat treatment effect far better than that of aluminum-zinc binary alloys.

Sheet ng aluminyo / Ang plate 7075-T6/T651 ay karaniwang ginagamit para sa aerospace, militar, at mga aplikasyon ng automotiko. 7075 aluminyo is the strongest aluminum, na may lakas ng maraming mga steels, habang pinapanatili ang magaan na katangian ng aluminyo at paglaban sa kaagnasan.

| haluang metal | init ng ulo | kapal | lapad |

| 7075 | T651 | 4-260mm | 1200-3800mm |

| 7075 | T7651 | 4-260mm | 1200-3800mm |

| 7075 | T7351 | 4-260mm | 1200-3800mm |

Mechanical properties

| Alloy state | Direction | kapal (mm) | Tensile strength | Ang yield Lakas | Breaking Elongation | pamantayan |

| 7075-T651 | LT | 6-260 | 570-590Mpa | 495-515Mpa | 10-13.5 | GB/T3880 |

| 7075-T7651 | LT | 6-102 | 550-560Mpa | 480-490Mpa | 10.5-12.5 | AMS4045K |

| 7075-T7351 | LT | 6-102 | 500-520Mpa | 420-435Mpa | 10-12.5 | AMS4078 |

aluminyo 7075 is a member of the 7000 serye, which has zinc as its main alloying component and is well known for its extraordinarily high strength. Tempering treatment can then further enhance its high mechanical strength. This property makes alloy 7075 very popular in the aerospace and defense industries.

Its strength is comparable to that of many types of steel, but it has a much lower density. The alloy is an excellent substitute to steel in high-stress applications. It also excels in withstanding fatigue stress, rendering it very reliable, a quality much sought after in the industries mentioned above.

haluang metal 7075 offers only average corrosion resistance, an outcome of the small amount of copper included in its chemical composition. It also features reasonable machinability and poor forming and weldability. Another drawback of this alloy is that it has a comparatively high-cost relative to other aluminum alloys due to its exceptionally high strength.

-

-

-