paglalarawan

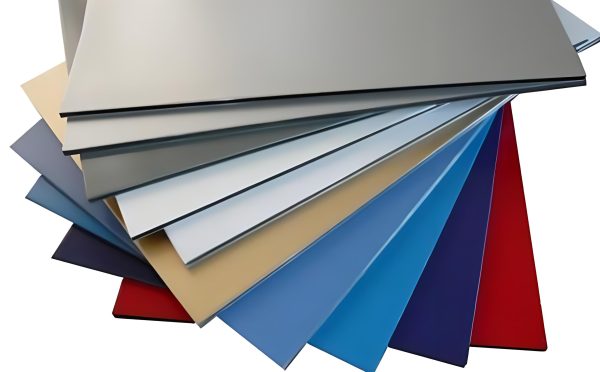

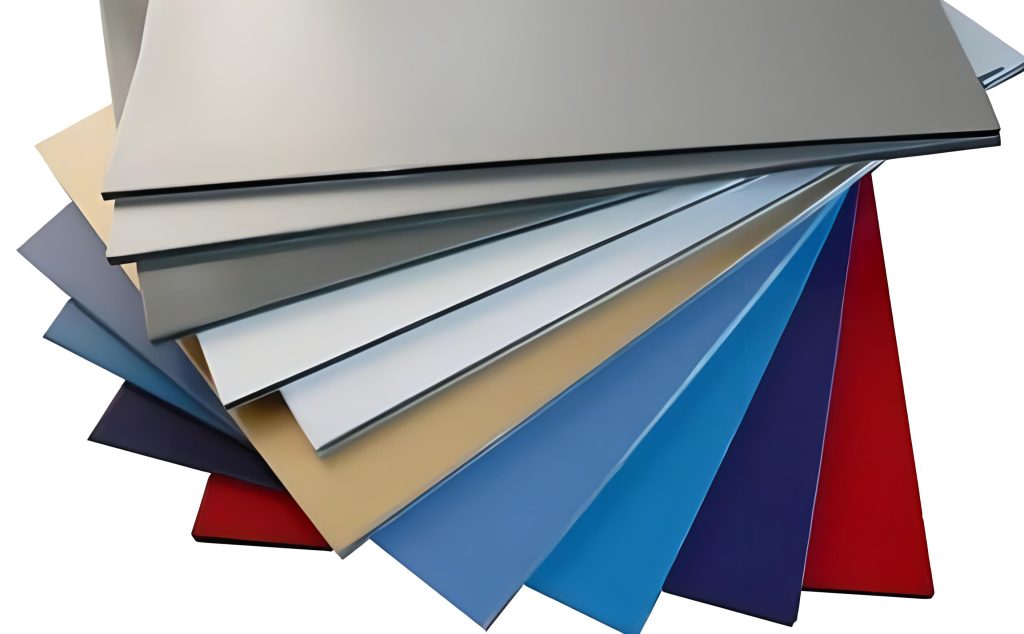

Aluminyo composite panel (ACP) is a flat panel made up of two thin aluminium sheets bonded to a non-aluminium core, usually made of polyethylene (PE) or fire-resistant material (FR). The aluminium sheets are typically coated with a paint finish or a protective film to enhance durability and aesthetics. ACP is commonly used in the construction industry for external cladding, panloob na dekorasyon, signage, and other architectural applications due to its lightweight, paglaban sa panahon, and versatility.

Versatility of Aluminium Composite Panel

Aluminyo composite panel (ACP) are highly versatile and can be used in a wide range of applications. Here are some of the key areas where ACPs demonstrate their versatility:

1. Architecture and Construction: ACPs are commonly used in the construction industry for cladding, façade systems, and interior design. They offer a lightweight and durable solution that can be easily installed. ACPs come in various colors, finishes, and textures, allowing architects and designers to achieve their desired aesthetic.

2. Signage and Advertising: ACPs are widely used for signage and advertising purposes due to their smooth surface, which provides an excellent base for printing graphics and text. They can be easily cut and shaped into different sizes and designs, making them ideal for creating eye-catching signs and billboards.

3. Transportasyon: ACPs are used in the transportation industry for manufacturing bus bodies, railway interiors, and aircraft interiors. Their lightweight nature helps reduce the overall weight of the vehicle, resulting in improved fuel efficiency. Bukod pa rito, ACPs offer excellent insulation properties, contributing to the comfort of passengers.

4. Retail and Commercial Spaces: ACPs are commonly used in retail and commercial spaces for wall cladding, partition, and decorative elements. They can be customized to match the desired theme or branding of a space. ACPs also offer easy maintenance and can withstand high traffic areas.

5. Industrial Applications: ACPs are used in various industrial applications, including clean rooms, pharmaceutical manufacturing facilities, and food processing plants. Their non-toxic and non-absorbent properties make them suitable for environments that require strict hygiene standards.

6. Furniture and Interior Design: ACPs are increasingly being used in furniture and interior design due to their versatility and aesthetic appeal. They can be used for creating cabinets, countertops, wall panels, and decorative elements. ACPs offer a wide range of finishes, including wood grain and metallic, allowing designers to achieve a desired look.

Overall, the versatility of aluminium composite panels makes them a popular choice in many industries. Their lightweight, tibay, ease of installation, and aesthetic options make them a versatile material for various applications.

Specification of Aluminium Composite Panel

| lapad(mm) | Standard 1220mm, 1250mm, options 900mm, 1500mm, 2000mm,

or any other width |

| haba(mm) | Standard 2440mm,options: 3050mm, 5000mm, 5800mm, or any other

length that can be put into a 20gp container |

| Panel

kapal(mm) |

Standard thickness: 3mm, 4mm, options: 1mm, 2mm, 5mm,

6mm,7mm, 8mm,etc |

| aluminyo

kapal(mm) |

0.5mm, 0.45mm, 0.4mm, 0.35mm, 0.3mm, 0.25mm, 0.21mm,

0.18mm,etc |

| Coating | PE, HDPE, PVDF, FEVE, Epoxy coating,etc |

| Kulay | Solid, metallic, high gloss, pearl, spectra mirror,stone look,

wood look,brushed,etc |

| timbang | 5-6.5kg/Square meters, based on 4mm thickness

3-4.5kg/Square meters, based on 3mm thickness |

| Function | Firefroof, Mould Proof, self-cleaning, Anti-Static, Antibacterial,etc |

| Sertipikasyon | SGS / CE / CTC / ISO 9001:2008 / ISO 14001:2004 /

GB/T 1774-1999,etc |

Aluminium composite panel can be used for building exterior walls, curtain wall panels, renovation of old buildings, interior wall and ceiling decoration, advertising signs, display stands, and purification and dust-proof projects.

Are Aluminium Composite Panels Fire Resistant?

Aluminyo composite panel (ACP) can vary in terms of fire resistance depending on their composition and the specific manufacturer. However, ACPs are generally considered to have good fire-resistant properties. The core material of the panel, which is typically made of polyethylene (PE) or fire-retardant (FR) materials, plays a significant role in determining the fire resistance.

PE core ACPs are less fire-resistant compared to FR core ACPs. PE cores have a lower melting point and can contribute to the spread of fire. On the other hand, FR core ACPs are designed to have higher fire resistance and are less likely to contribute to the spread of flames. These panels are often used in buildings where fire safety is a concern.

It is important to note that fire resistance ratings for ACPs can vary, and it is advisable to consult the manufacturer’s specifications and certifications to ensure compliance with fire safety regulations. Bukod pa rito, installation methods and proper fire safety measures should be followed to enhance the overall fire resistance of the building.

In order to meet the needs of people in various types of buildings, aluminium cladding designs are also different. In addition to the various colors of painting aluminium cladding, there are also many other treatments of aluminum panels for sale.

Corrugated aluminium cladding. Corrugated aluminum composite panel is a kind of corrugated aluminum sheet, which is formed by rolling pressure of the aluminum sheet. Corrugated aluminium panel is suitable for all kinds of industrial and civil building walls and interior decoration and so on. At saka, corrugated aluminum cladding has long service life and easy to maintain.

Perforated aluminum cladding. Perforated aluminum composite panel is perforated on the surface of aluminum composite panel cladding. The holes are varying in size and shape.Perforated aluminum cladding is widely used in daily life, it can be used as decorative aluminium sheet, beautiful and graceful. It also can be made into a variety of utensils, corrosion resistant and durable.

Brushed aluminium composite panel. The brushed aluminium composite sheet is made by repeatedly using sandpaper to scratch the surface of aluminium alloy sheet. This kind of alu clad aluminium composite panel is not only beautiful but can also resistant to erosion.

In addition to these common panel aluminium, there are many other types of aluminum panels for sale, such as aluminium interlocking panels, aluminium composite panel wood finish, aluminium composite panel bunnings and so on. If you want more aluminum cladding details and aluminum composite panel thickness, lamang makipag-ugnay sa amin, our professional experts will offer you the most comprehensive answers.

-

-

-