paglalarawan

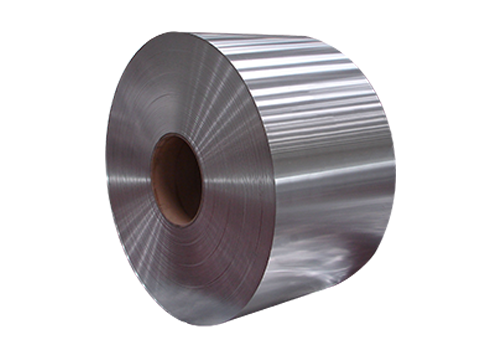

Battery aluminum foil, also known as battery aluminum foil or lithium battery-specific aluminum foil, is a material specially used to manufacture the positive electrode collector of lithium batteries.

Battery aluminum foil has high conductivity, magandang ductility, corrosion resistance and excellent molding processability, and is an important component of lithium batteries.

The thickness of battery aluminum foil is usually between 0.01mm~0.2mm, and the width is in the range of 600mm~2000mm.

The surface roughness is required to ensure that the positive active material can be evenly coated and tightly adhered to the surface of the aluminum foil, thereby improving the capacity and performance of the battery.

During the production process, battery aluminum foil needs to go through multiple processes, including smelting, casting, gumugulong, heat treatment, surface treatment, etc.

Una, the aluminum ore is refined and smelted to obtain high-purity liquid aluminum, and then the liquid aluminum is cast into slabs or rolled into aluminum plates through a continuous casting or rolling process.

Then, the aluminum plate is subjected to cold rolling, intermediate annealing and finish rolling to obtain the required thickness and surface quality.

Sa wakas, the aluminum foil is subjected to surface treatment, such as cleaning, pickling, passivation, at iba pa, to improve its corrosion resistance and coating performance.

The quality of battery aluminum foil has a direct impact on the performance of lithium batteries. If the aluminum foil has insufficient conductivity, excessive surface roughness, or defects, it may lead to increased internal resistance, reduced capacity, and shortened cycle life of the battery.

kaya, the quality of aluminum foil needs to be strictly controlled during the production process to ensure that it meets the requirements of lithium batteries.

Sa pangkalahatan, battery aluminum foil is one of the important materials in lithium battery manufacturing, and its quality and performance have an important impact on the performance and safety of lithium batteries.

With the rapid development of new energy vehicles and energy storage, the market demand for battery aluminyo foil is also growing.

The brand of battery aluminum foil mainly indicates its alloy composition and performance characteristics. In battery manufacturing, commonly used battery aluminum foil grades include 1060, 1050, 1145, 1235, etc.

Among them, 1060 at 1070 are two commonly used aluminum foil grades for lithium batteries.

1060 aluminum foil: This aluminum foil has high purity, Mababang densidad, and good electrical conductivity. It is mainly used as negative electrode material for lithium-ion batteries.

1070 aluminum foil: This aluminum foil has high purity and good surface flatness, and is suitable for positive electrode materials in lithium-ion batteries.

In addition to these two commonly used grades, other grades of aluminum foil are also used according to different application fields and process requirements.

These grades of aluminum foil may have different alloy compositions, thicknesses, widths, strengths and other performance characteristics to meet the needs of specific batteries.

-

-

-