Açıklama

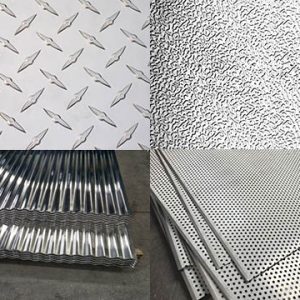

Perforated aluminum sheet is an aluminum sheet with a porous structure, which is mainly made by punching or cutting holes of different shapes and sizes on pure aluminum or aluminum alloy materials.

This material has many characteristics and a wide range of applications. The following is a detailed introduction to perforated aluminum sheet:

Delikli alüminyum levha refers to a rectangular material with a rectangular cross section and uniform thickness made of pure aluminum or aluminum alloy material through pressure processing (such as shearing or sawing), and a porous structure is formed on its surface through a punching process.

What is the main features of delikli alüminyum levha?

Light material: The density of aluminum is relatively low, which makes the overall weight of perforated aluminum plate light, easy to transport and install.

High temperature and corrosion resistance: Aluminum alloy materials have good high temperature and corrosion resistance, suitable for a variety of harsh environments.

Non-flammable: Aluminum is a non-combustible material, which improves the safety of the building.

Good stability: Özel tedaviden sonra, the perforated aluminum plate has good dimensional stability and flatness.

Strong decorative effect: Through different hole designs and color matching, a variety of decorative effects can be achieved.

- Malzeme: High-grade Perforated Aluminum Sheets

- Kalınlık: 0.1mm~12mm

- Mesh Length:1.8m~2.44m

- Mesh Width:0.8m/1.22m

- Perforated area percent: itibaren 7% için 83%

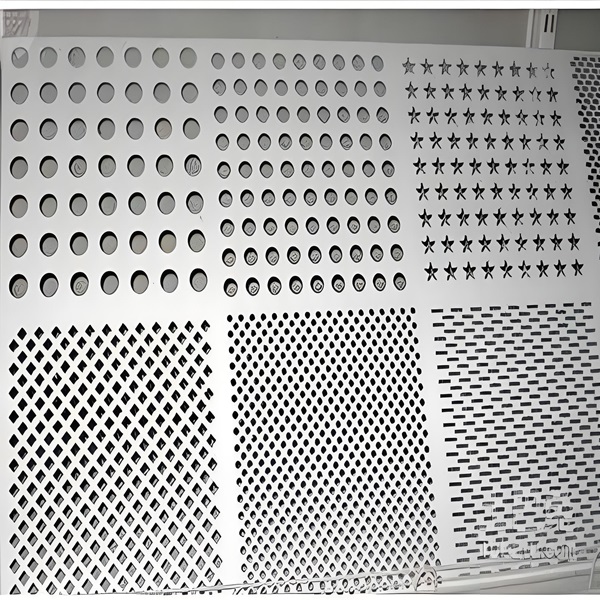

- Hole Type: Elmas, round, kare, rectangular, triangle, hexagon, hexagonal, oluklu, oval, club, cross, louver, vb.

1060 ve 1050 perforated aluminum sheets are both common aluminum alloy perforated sheets. They have some similarities and differences in material properties, application areas, processing and installation.

alüminyum içeriği 1050 perforated aluminum plate reaches more than 99.5%, which is a kind of high-purity industrial pure aluminum.

alüminyum içeriği 1060 perforated aluminum plate is slightly higher than 1050, reaching 99.60%, which makes its material relatively softer.

Both have excellent electrical conductivity, termal iletkenlik, korozyon direnci, and good plasticity and processing properties. Yine de, due to the slightly higher aluminum content of 1060, its ductility and plasticity may be slightly better than 1050.

Perforated aluminum sheets are widely used in many fields due to their unique properties and advantages:

Mimari dekorasyon: used for indoor and outdoor architectural decoration, such as exterior wall decoration, tavanlar, bölme duvarları, stair handrails, vb. Through different hole designs, patterns, text or geometric figures can be formed to enhance the beauty and artistry of the building.

Ventilation and heat dissipation: Due to its good air permeability, perforated aluminum sheets can be used for the outer cover or grid of ventilation and heat dissipation equipment, such as coolers, fans, klimalar, vb.

Filtration field: As a filter material, it is used to filter air, liquid or solid particles. By adjusting the pore size and hole shape, different filtering accuracy and effects can be achieved.

Acoustic sound insulation: It is used to make acoustic sound insulation materials such as sound-absorbing panels and sound insulation screens to effectively absorb and isolate sound waves, improve sound quality and reduce noise pollution.

Safety protection: used to make security windows, guardrails and other security protection equipment, which are transparent and meet safety requirements.

Other fields: such as display racks, furniture finishes, car interiors, electronic product housings, vb.

-

-

-